Technology for producing needle embroidery wall cloth

A production process and wall covering technology, applied in the production technology field of decorative wall coverings, can solve the problems of difficult color control, unclear patterns, insufficient three-dimensional effect of surface patterns, etc., and achieve improved decorative level, high ornamental value and three-dimensional effect strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

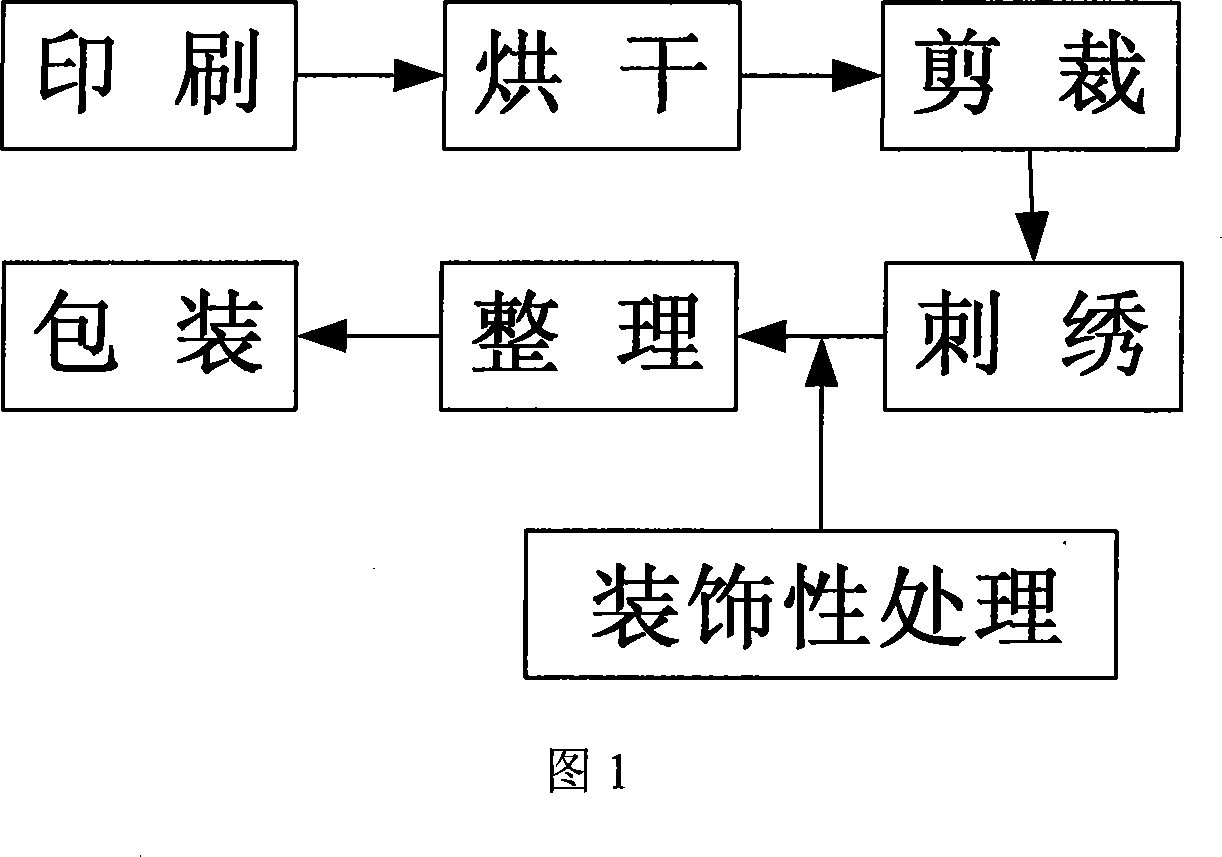

[0026] Embodiment 1 As shown in FIG. 1 , it is a flow chart of the production process of the needle-embroidered wall covering, which mainly includes printing, drying, cutting, embroidery, decorative treatment, finishing and packaging. Choose non-woven fabric as the base material of the wall covering. First, use the gravure printing machine to print and color the pattern on the surface of the base material of the wall covering with ink, and dry the printed pattern on the surface of the base material of the wall covering through an oven at 180°C while printing. ; Then trim the wall covering base material after printing and drying, and cut it into a semi-finished wall covering with a fixed width of 53cm and a length of 10m; then use polyester embroidery thread to embroider the stitches per meter in the length direction with 80,000 needles Ratio, the surface of the semi-finished wall covering after cutting is embroidered corresponding to its pattern to obtain an embroidered wall co...

Embodiment 2

[0027] Example 2 Select cotton gauze as the base material of the wall covering. First, use a rotary screen printing machine to print and color the surface of the base material of the wall covering with ink, and print the pattern on the surface of the base material of the wall covering through an oven at 250°C while printing. Drying; then trimming the printed and dried wall covering substrate, cutting it into a semi-finished wall covering with a fixed width of 70cm and a length of 10m; then using a towel thread, the number of embroidery needles per meter in the length direction is 60,000 According to the needle ratio, the surface of the semi-finished wall covering after cutting is embroidered corresponding to its pattern to obtain an embroidered wall covering; then the embroidered wall covering is decorated, and sequins, hot diamonds, and fur are pasted on the surface of the embroidered wall covering; The back of the embroidered wall covering is trimmed and leveled; finally, the...

Embodiment 3

[0028] Example 3 Select wallpaper as the base material of the wall covering. First, use a gravure printing machine to print and color the surface of the base material of the wall covering with ink, and at the same time, dry the printed pattern on the surface of the base material of the wall covering through an oven at 100°C. Dry; Trim the wall covering base material after printing and drying, and cut it into a semi-finished wall covering with a fixed width of 1m and a length of 10m; then use cotton thread to embroider at a rate of 40,000 stitches per meter in the length direction, Embroidery the surface of the semi-finished wall covering after cutting according to its pattern to obtain the embroidery wall covering; trim and level the back of the embroidery wall covering; finally wrap the embroidery wall covering into a cylinder shape and use a packaging shrinking machine to shrink the embroidery wall covering. Packing to get the finished product of the needle-embroidered wall c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com