Method for manufacturing embroidered wallcovering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

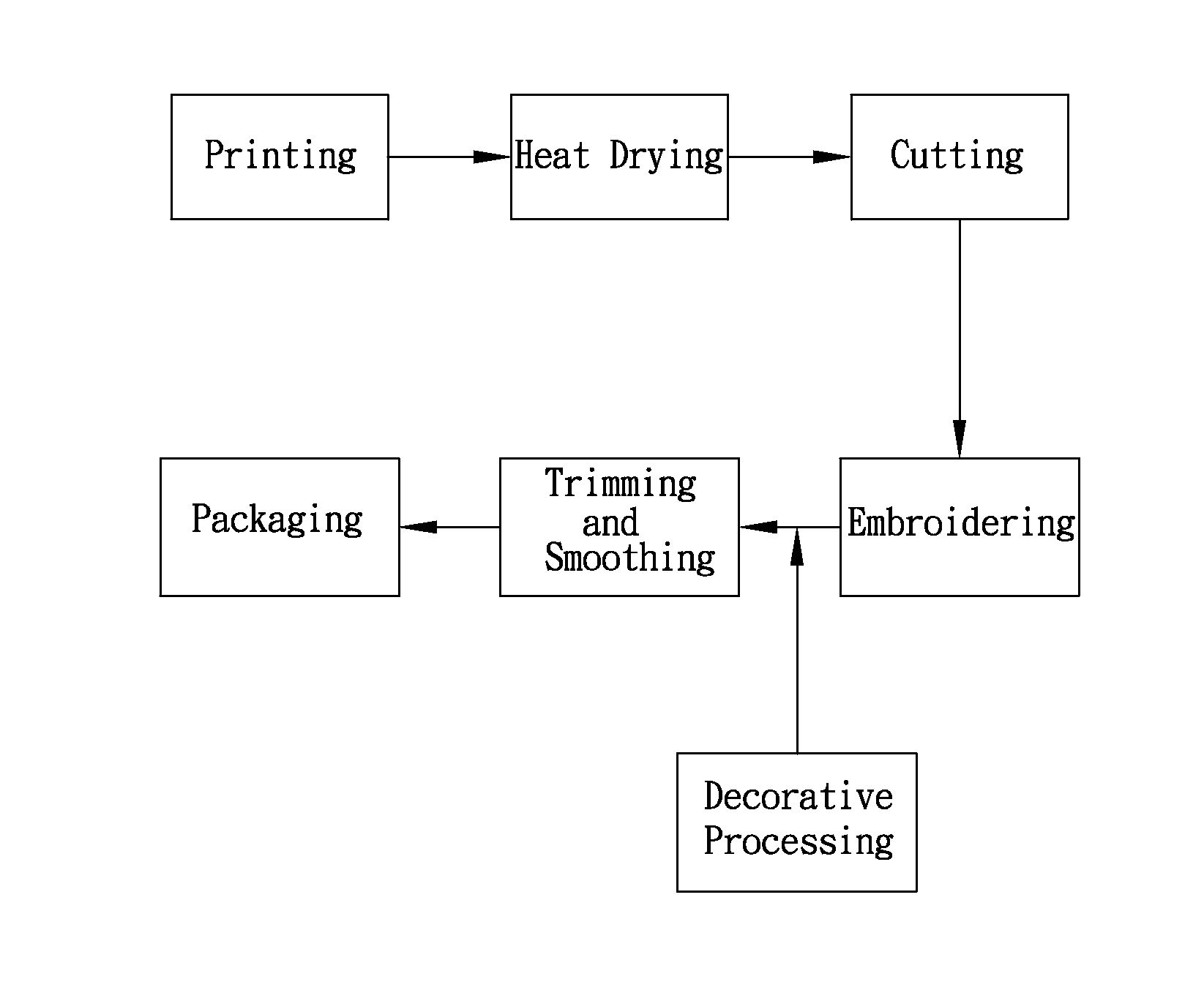

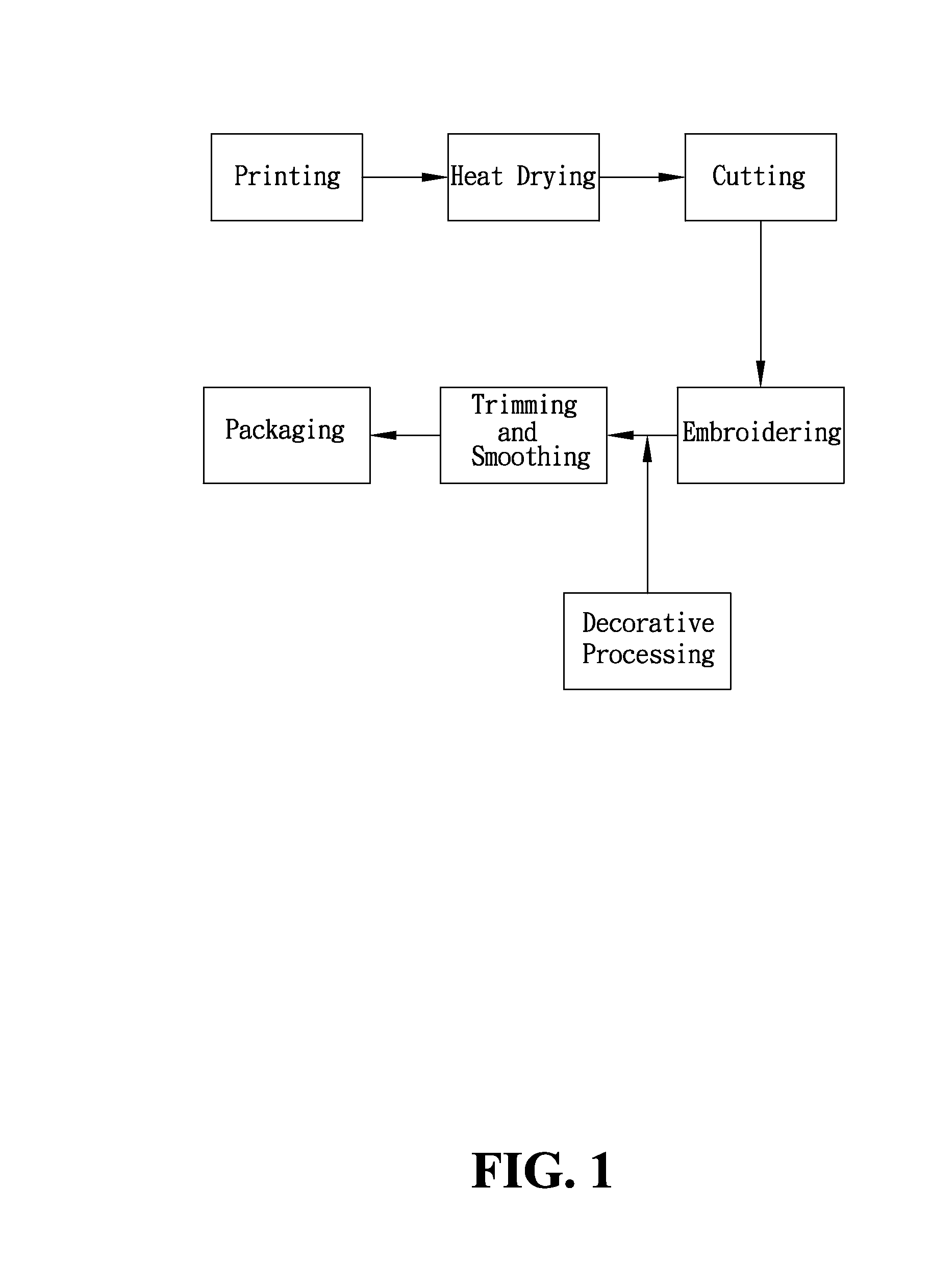

[0017]Referring to FIG. 1, a method for manufacturing an embroidered wallcovering according to the present invention includes printing, heat drying, cutting, embroidering, decorative processing, trimming, and packaging. A method for manufacturing an embroidered wallcovering according to the present invention includes the following steps. (a) A non-woven material is chosen as a base material of a wall cloth. Using a gravure press with water soluble inks, print patterns are printed on the base material. In the mean time of printing, the base material passes an oven and is heat dried at a temperature of 180 degree Celsius. (b) The base material is cut into the semi-finish wall cloth having 10 m in length and 53 cm in width. (c) Thread patterns, which is corresponding to the print patterns, are embroidered on the semi-finish wall cloth to get an embroidered wall cloth. Polyester threads are used and a thread count of the thread patterns is under eighty thousand per meter in lengthwise d...

second embodiment

[0018]A method for manufacturing an embroidered wallcovering according to the present invention includes the following steps. (a) Cotton textile is chosen as a base material of a wall cloth. Using a cylinder screen press with water soluble inks, print patterns are printed on the base material. In the mean time of printing, the base material passes an oven and is heat dried at a temperature of 250 degree Celsius. (b) The base material is cut into the semi-finish wall cloth having 10 m in length and 70 cm in width. (c) Thread patterns, which is corresponding to the print patterns, are embroidered onto the semi-finish wall cloth to get an embroidered wall cloth. Caddices are used and a thread count of the thread patterns is under eighty thousand per meter in lengthwise direction. (d) A decoration process is operated, which beads, sequins, furs, rhinestones are adhered onto the embroidered wall cloth. (e) A back of the wall cloth is trimmed and smoothed. (f) The wall cloth is curled up ...

third embodiment

[0019]A method for manufacturing an embroidered wallcovering according to the present invention includes the following steps. (a) Paper is chosen as a base material of wallpaper. Using a gravure press with water soluble inks, print patterns are printed on the base material. In the mean time of printing, the base material passes an oven and is heat dried at a temperature of 100 degree Celsius. (b) The base material is cut into the semi-finish wallpaper having 10 m in length and 1 m in width. (c) Thread patterns, which is corresponding to the print patterns, are embroidered onto the semi-finish wallpaper. Cotton threads are used and a thread count of the thread patterns is under eighty thousand per meter in lengthwise direction. (d) A back of the wall cloth is trimmed and smoothed. (e) The wallpaper is curled up into a roll and the roll is wrapped in a shrink film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com