Electric and manual dual-purpose jack

A kind of jack and manual technology, applied in the direction of lifting device, etc., can solve the troublesome, laborious and time-consuming problems of car tire replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

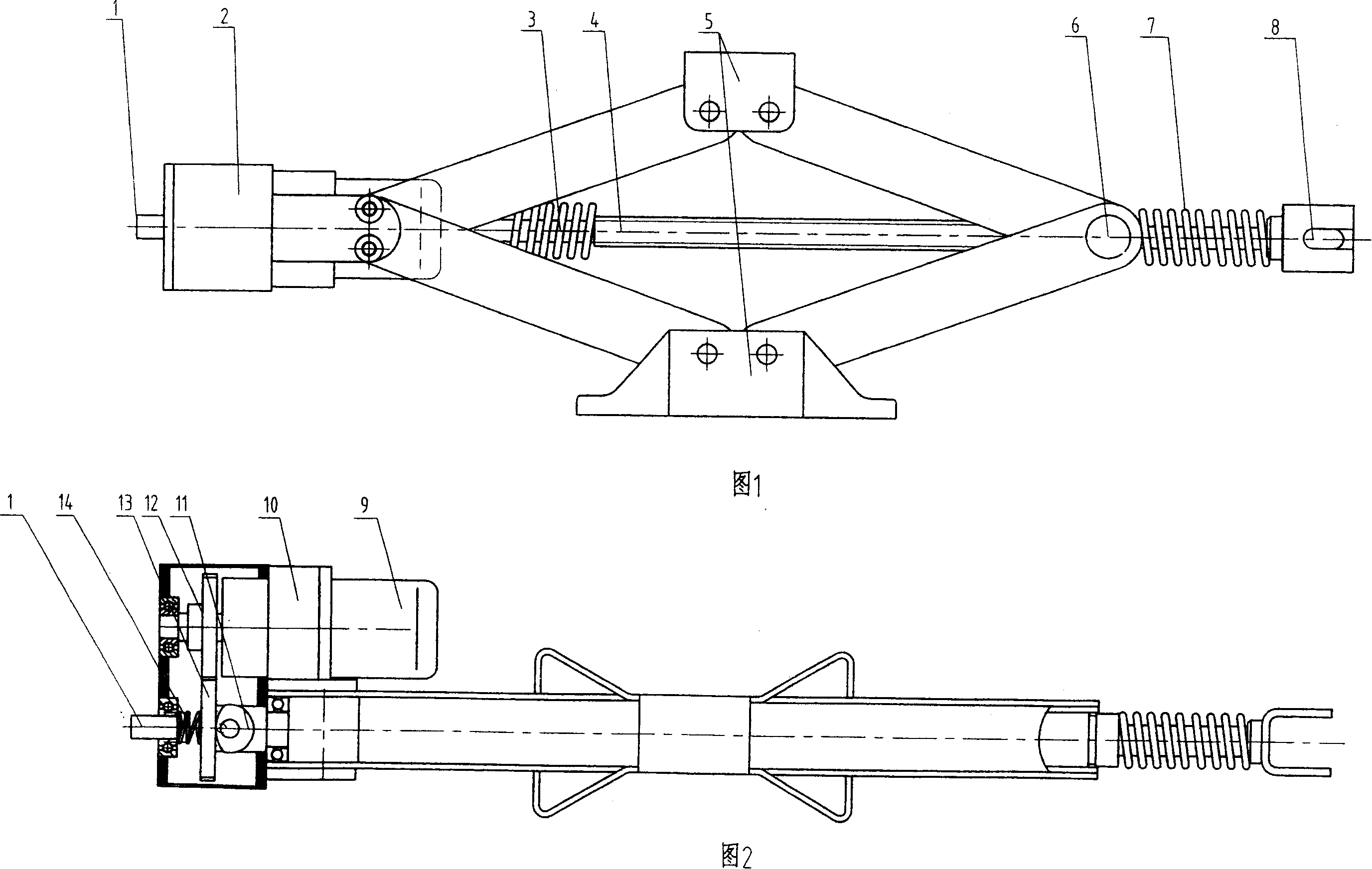

[0013] Referring to Fig. 1 and Fig. 2, electric jack of the present invention includes support 5, screw mandrel 4, motor 9, multistage planetary reducer 10, eccentric wheel 11 and two return force springs 3,7. Bracket 5 is a scissor-type bracket with four arms up and down symmetrical. Reducer 10 is coaxially connected with motor 9. Transmission gear 12 is coaxially connected with reducer 10. Transmission gear 12 is also meshed with clutch gear 13. Clutch gear 13 passes through the screw rod The shaft pin is sleeved on the screw rod 4, and a return spring 14 is sleeved between the clutch gear 13 and the handle interface 1. On the other side of the clutch gear 13, there is an eccentric wheel 11 with a rotating handle, and the screw rod 4 has two There is no thread at the end, and one end of the screw rod 4 is socketed with the two arms of the bracket 5 through the movable nut 6, and the two ends of the screw rod 4 have hand handle interfaces 1, 8, and there are sockets between th...

Embodiment 2

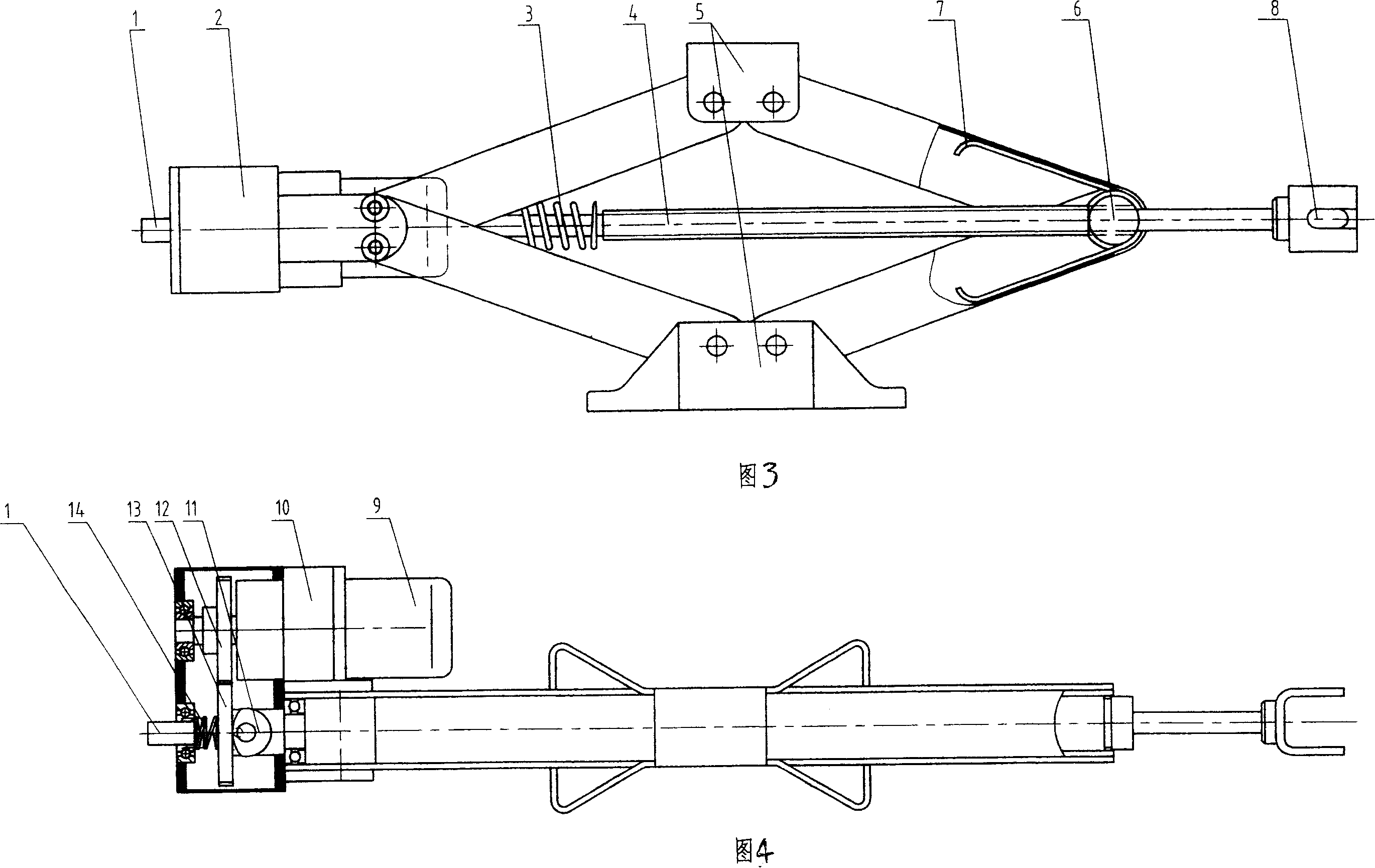

[0015] Referring to Fig. 3 and Fig. 4, the electric and manual dual-purpose jack of the present invention includes a bracket 5, a screw mandrel 4, a motor 9, a multistage planetary reducer 10, an eccentric wheel 11 and two return springs 3,7. Bracket 5 is a scissor-type bracket with four arms up and down symmetrical. Reducer 10 is coaxially connected with motor 9. Transmission gear 12 is coaxially connected with reducer 10. Transmission gear 12 is also meshed with clutch gear 13. Clutch gear 13 passes through the screw rod The shaft pin is sleeved on the screw rod 4, and the return spring 14 is sleeved between the clutch gear 13 and the handle interface 8. On the other side of the clutch gear 13, there is an eccentric wheel 11 with a rotating handle. One end of the screw rod 4 The two arms of the movable nut 6 and the bracket 5 are socketed, and the two ends of the screw rod 4 are threadless and connected to the return force springs 3, 7, wherein the return force spring 7 conne...

Embodiment 3

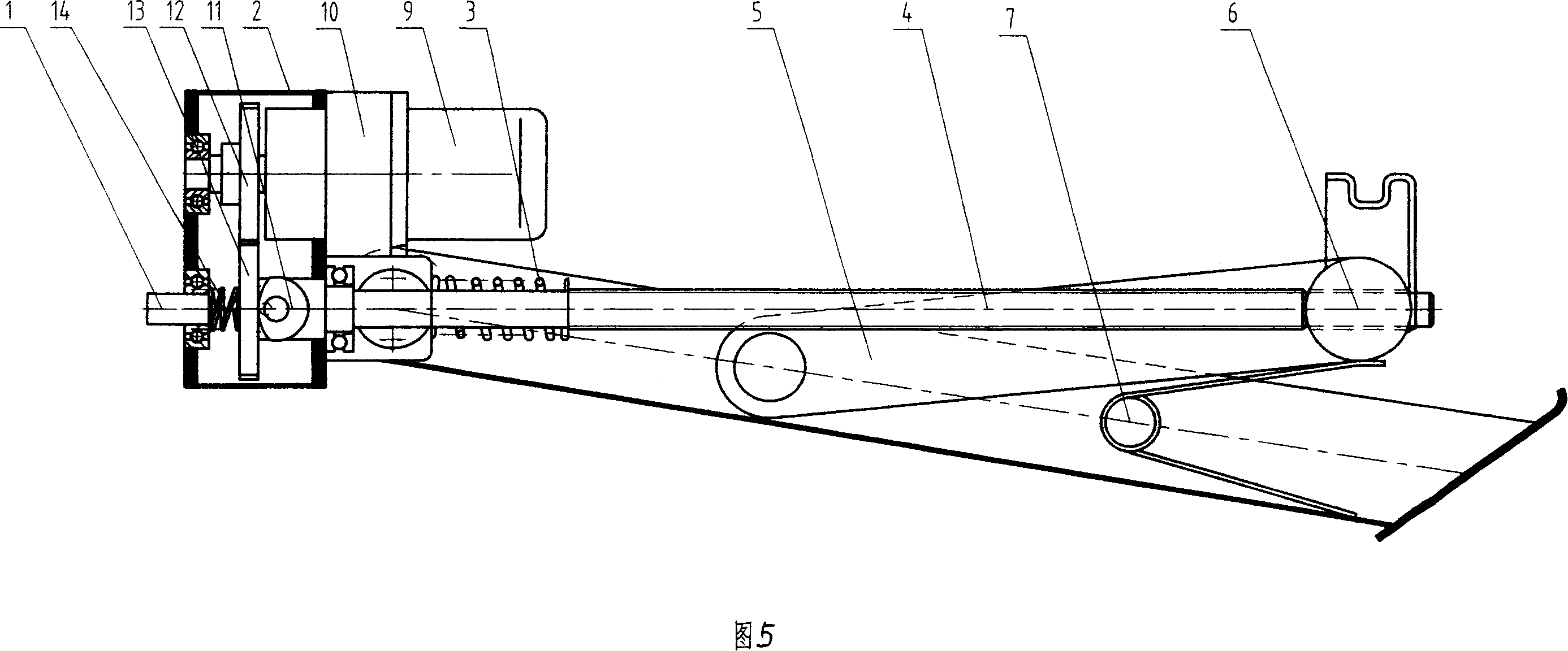

[0017] Referring to Fig. 5, the electric and manual dual-purpose jack of the present invention includes a bracket 5, a screw mandrel 4, a motor 9, a multistage planetary reducer 10, an eccentric wheel 11 and two return springs 3,7. The bracket 5 is a Y-shaped bracket with two arms movably connected, the speed reducer 10 is coaxially connected with the motor 9, the transmission gear 12 is coaxially connected with the speed reducer 10, and the transmission gear 12 is also meshed with the clutch gear 13, and the clutch gear 13 passes through the wire The shaft pin is socketed on the screw rod 4, and the return spring 14 is socketed between the clutch gear 13 and the handle interface 1. On the other side of the clutch gear 13, there is an eccentric wheel 11 with a rotating handle, and the screw rod 4 One end is socketed with one arm of the bracket 5 through the movable nut 6, and the two ends of the screw rod 4 have no thread and are connected with the return force springs 3, 7, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com