Electric millstone tile lifting appliance

A technology of grinding tiles and spreaders, which is applied in the direction of load hanging components, hoisting devices, track systems, etc., can solve the problems of cumbersome maintenance and lifting of grinding tiles, irregular shape of grinding tiles, narrow space, etc., and reduce labor investment, improve maintenance efficiency and reduce maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

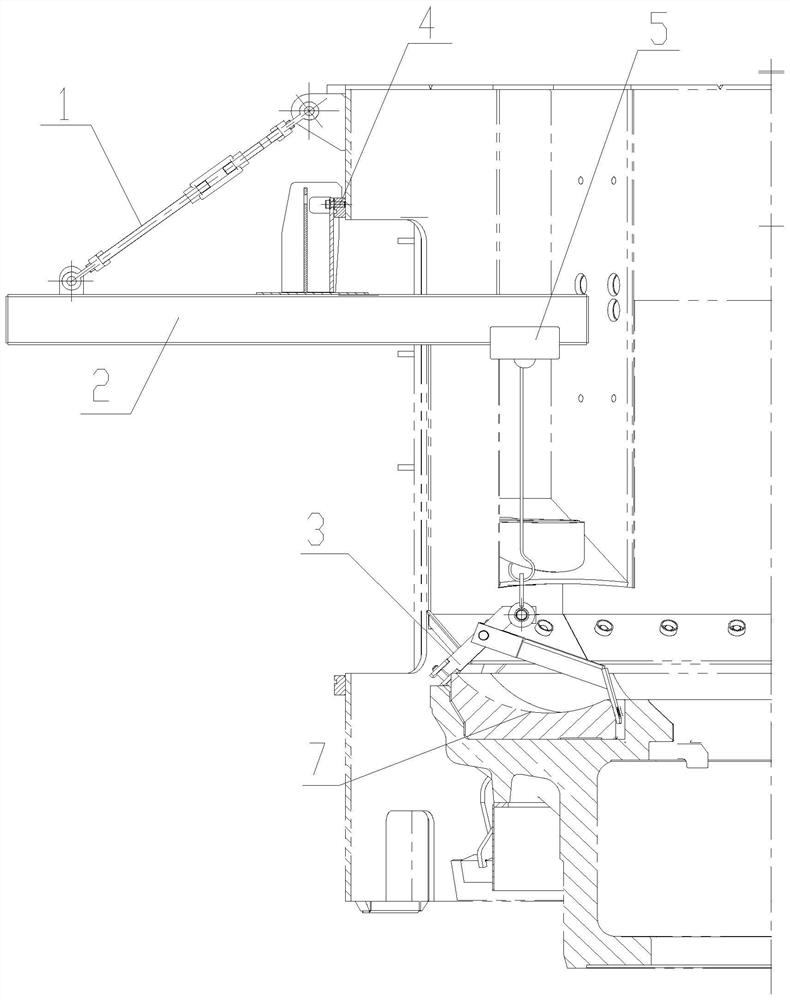

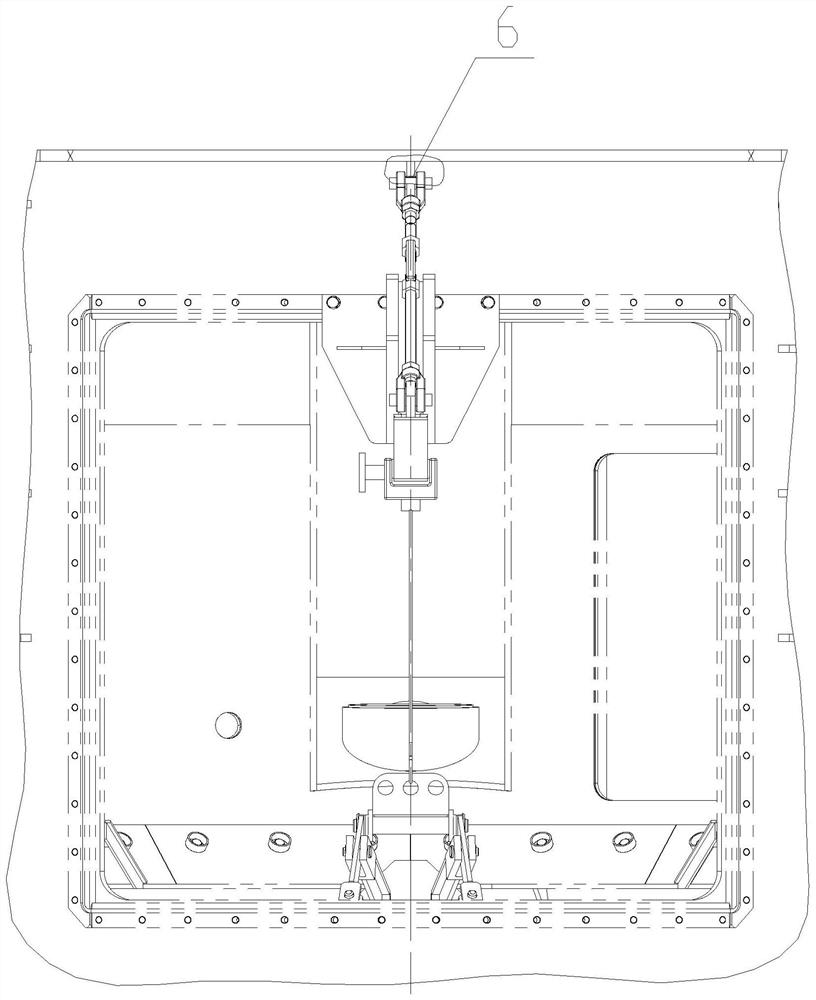

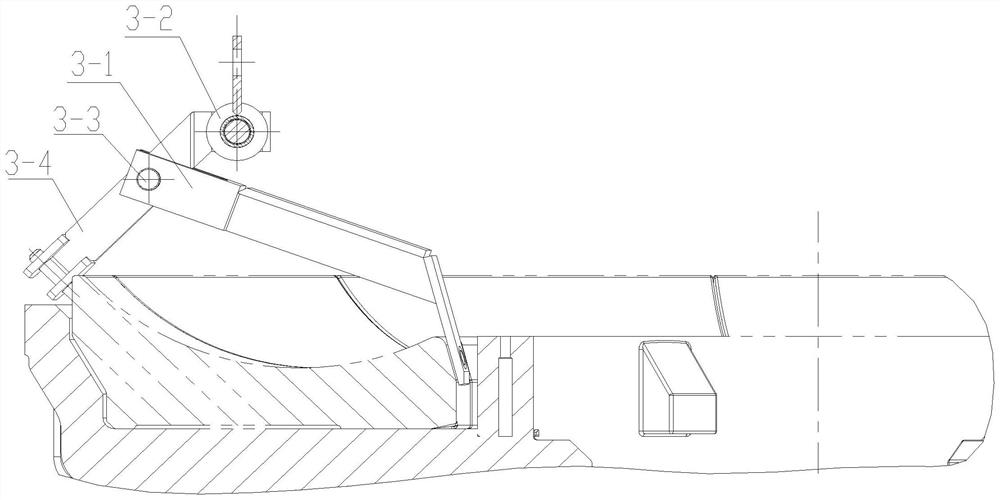

[0020] like Figure 1-Figure 2 As shown, the present invention provides a kind of electric mill tile spreader, and its structure is by rigging turnbuckle (1), hanging beam (2), hanging concrete (3), connecting bolt (4), electric hoist (5), sleeve pipe (6) and mopan tile (7), the mopan tile (7) is fixed by the hoisting concrete (3) when hoisting, the hoisting point end of the hoisting concrete (3) is connected with the electric hoist (5), and the electric hoist ( 5) Cooperate with the hanging beam (2), and use the hanging beam (2) as the track to realize the lateral movement of the electric hoist (5). One end of the hanging beam (2) is connected to the medium-speed coal mill The gantry of the frame body inspection door is fixed, and the other end is fixed on the lifting lug of the frame body in the medium-speed coal mill through the rigging turnbuckle (1) and the casing (6). The rigging turnbuckle (1) can adjust its own length. It is convenient to control the levelness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com