Square staff

A technology of wall foot and line board, which is applied in the field of building decoration materials, can solve the problems of inconvenient disassembly, insufficient thickness of the wall foot line, easy damage to the wall foot line, etc., and achieves the effect of improving the installation quality, facilitating the arrangement of hidden lines, and ensuring a stable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

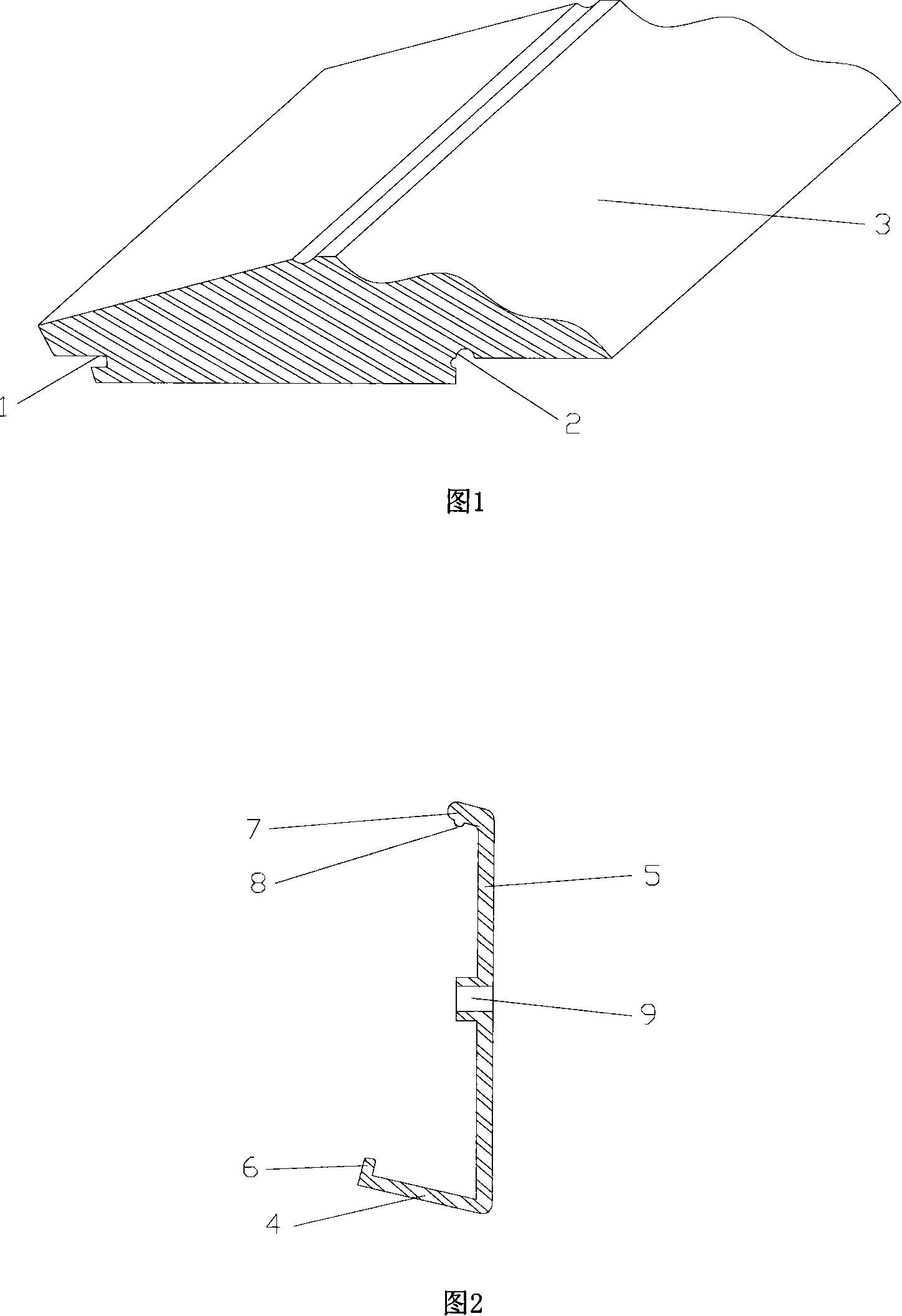

[0016] Embodiment 1: As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention includes skirting boards and fixed supports. Wherein, the fixed support is composed of the base plate 4 and the side plate 5, which is an integral structure, and the outer end of the base plate 4 is provided with an inwardly inclined convex strip 6, and the upper end of the side plate 5 is provided with a baffle plate bent to the inside of the side plate 5 7. Platforms corresponding to the inner side of the bottom plate 4 and the inner side of the baffle plate 5 are arranged longitudinally on the back of the skirting board, and grooves 1 matching the convex strips 6 are provided on the platforms corresponding to the inner side of the bottom plate 4 . The inboard of above-mentioned baffle plate 7 is longitudinally provided with boss 8, is provided with above-mentioned boss 8 on the skirting board back side platform corresponding with baffle plate 7 inner side and baffle plate 7 inner side and baffl...

Embodiment 2

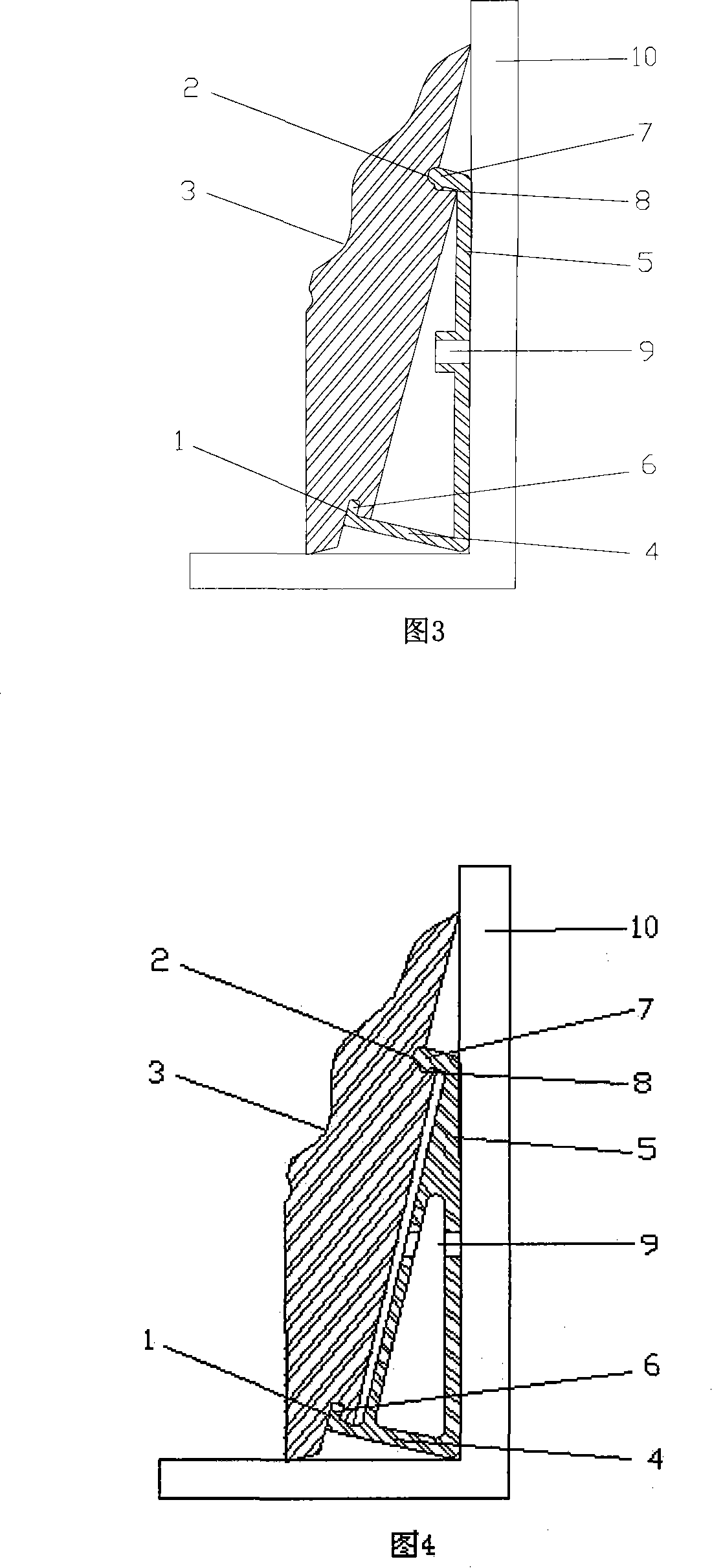

[0017] Embodiment 2: As shown in Fig. 4, other structures of this embodiment are the same as Embodiment 1, the difference is that the thickness of the fixing support is different, and this fixing method is more stable.

Embodiment 3

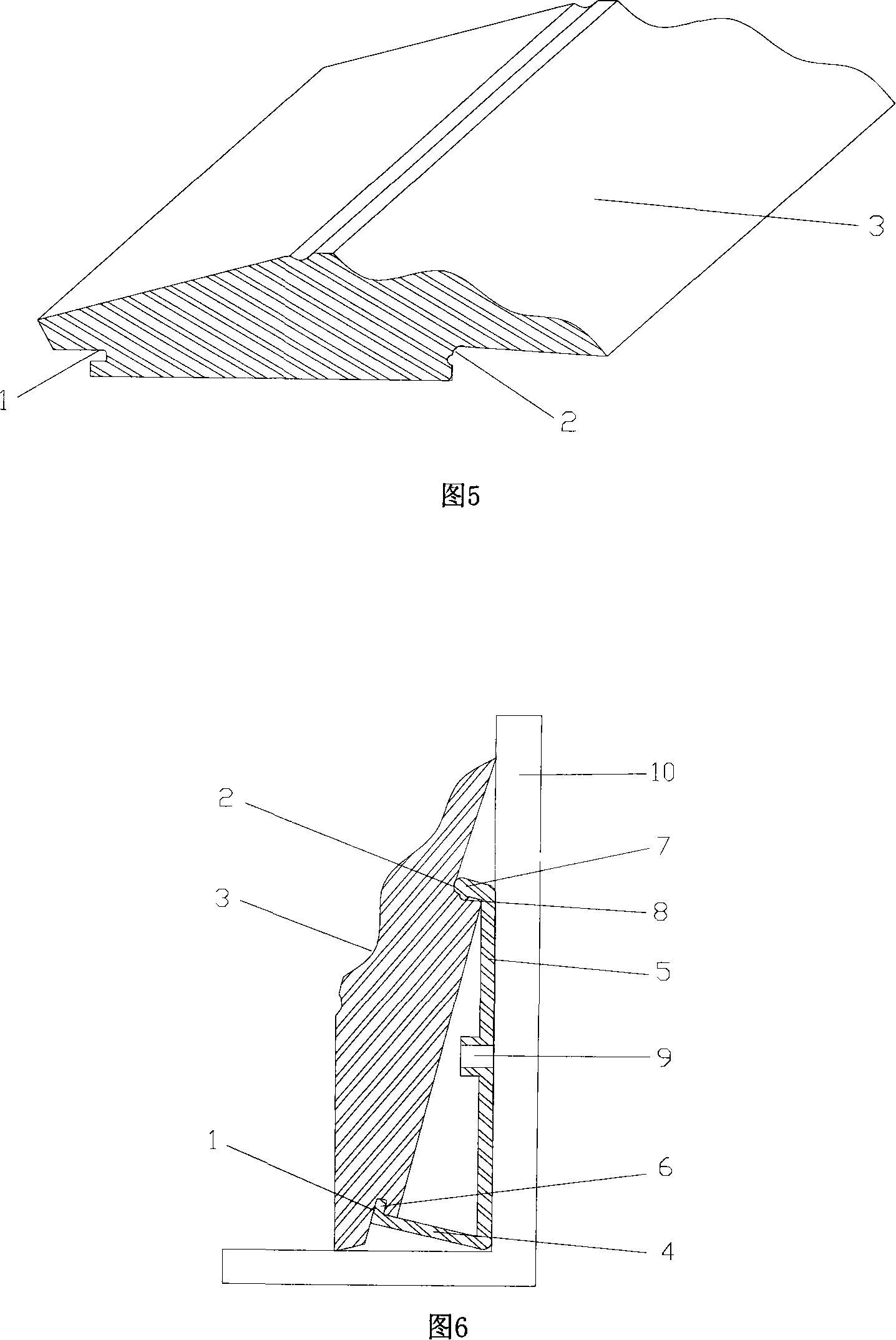

[0018] Embodiment 3: As shown in FIG. 5 and FIG. 6 , other structures of this embodiment are the same as those of Embodiment 1, the difference being that in this embodiment, the groove 2 only cooperates with the above-mentioned boss 8 .

[0019] During installation, first nail the fixed support on the wall surface 10 through the pin hole 9; then clamp the groove 1 at the lower part of the skirting board on the raised strip 6; finally, use the elastic force of the fixed support itself to make the Baffle plate 7 buckles the groove 2 on the top of the skirting board, and the skirting is fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com