A light emitting device including anti-reflection layer(s)

A light-emitting device and anti-reflection technology, which is applied in the direction of electric solid-state devices, electroluminescent light sources, instruments, etc., can solve problems such as the difficulty of preventing Newton's rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

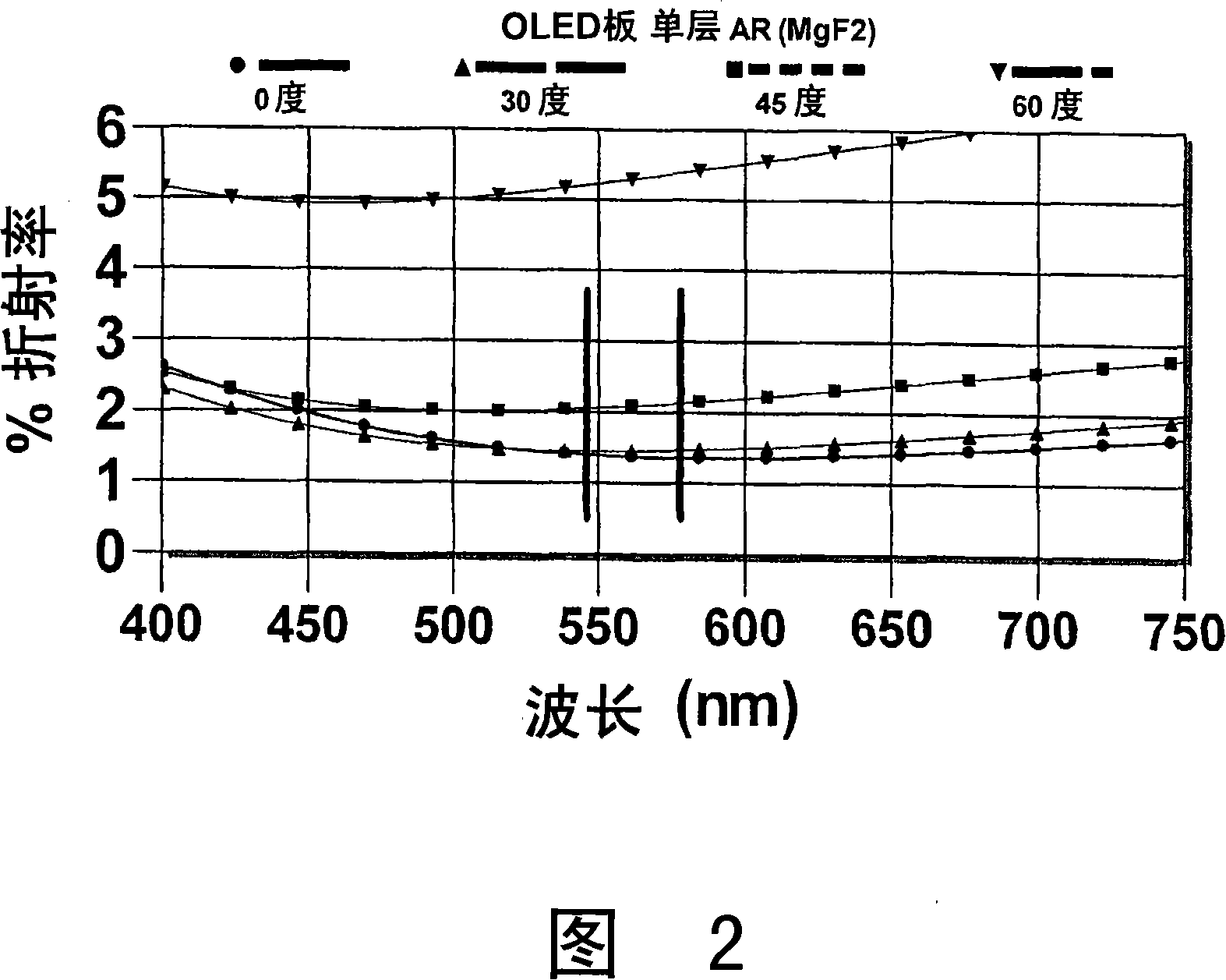

[0061] Example 1 - Monolayer MgF 2 coating

[0062] In the first example, a single layer of magnesium fluoride coating on a sheet of Eagle 2000TM One surface of the glass is modeled to simulate light-emitting devices covering the inner surface of the substrate. Eagle in this example 2000TM Glass has a refractive index of 1.507 at 589.3 nm, so based on the above theory, the target refractive index of the anti-reflection coating is 1.23 and an optical thickness of 147 nm. A single-layer magnesium fluoride coating has a refractive index of 1.38 and thus a physical thickness of approximately 107 nm.

[0063] Figure 2 shows the modeled refractive index of a single-layer magnesium fluoride coating at different angles of incidence. At a wavelength of 546 nm, this refractive index is approximately 1.4% when viewed from an angle of incidence of 0 to 30 degrees. At a 45 degree incidence angle, the refractive index is slightly greater than two percent, and at a 60 degree incidence a...

example 3- 4

[0070] Example 3 - Four layers of anti-reflective coating

[0071] In the third example, four layers of anti-reflective coating on Eagle 2000TM Overlay the modeling on the substrate. The four-layer coating includes 12 nm of niobium oxide, about 36 nm of silicon dioxide, about 110 nm of niobium oxide, and a top layer of 90 nm of silicon dioxide.

[0072] As shown in Figure 7, the modeled reflectance for light at angles of incidence up to 45 degrees is less than one percent for visible wavelengths below 630 nm. The model indicated that the coating composition was sufficient to reduce the appearance of Newton's rings at angles of incidence up to about 45 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com