Variable dry wall

A drywall and rib technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of low installation work efficiency, difficult renovation, and difficult disassembly of drywall, etc., so as to facilitate renovation, assembly and disassembly. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

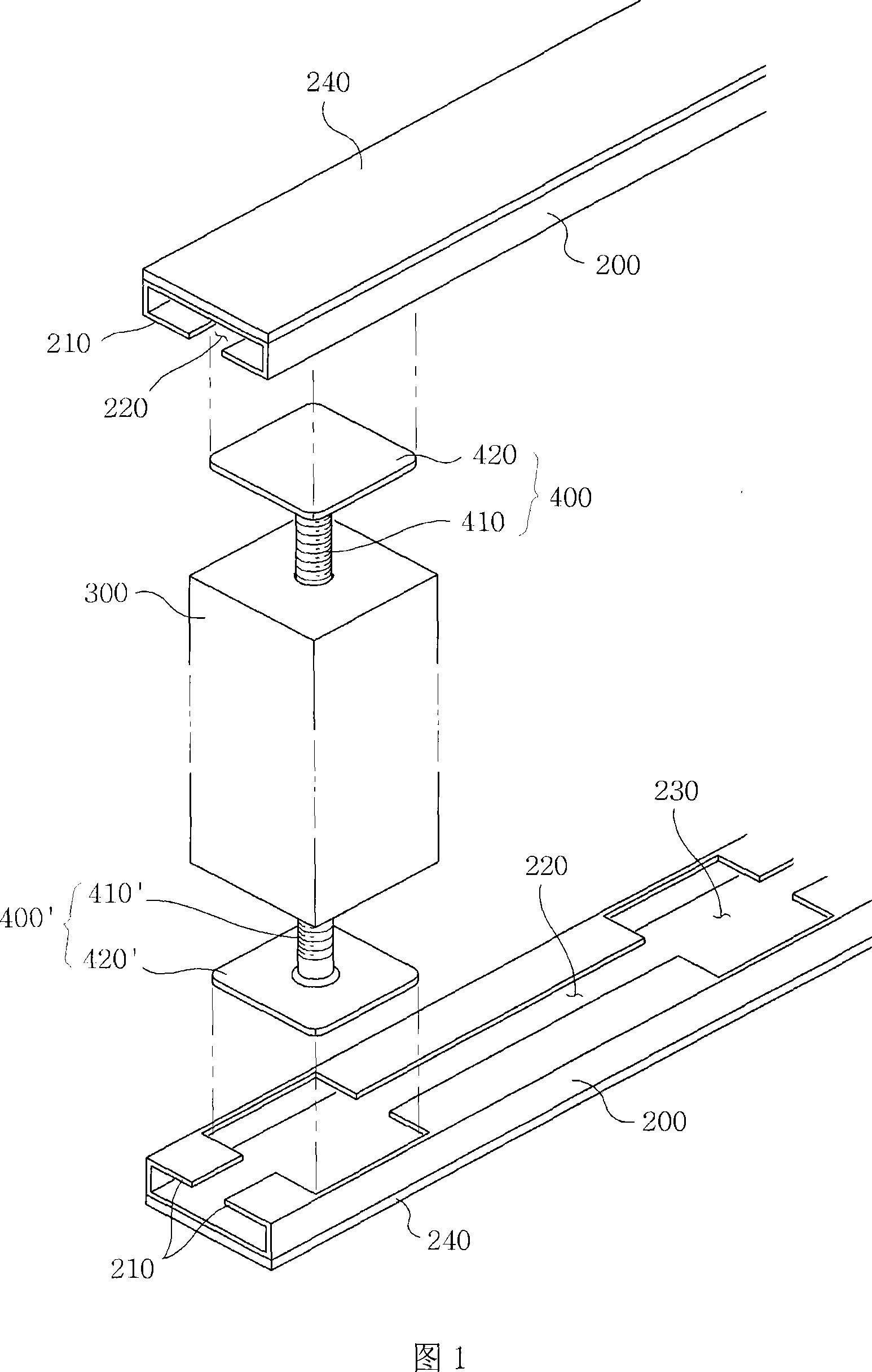

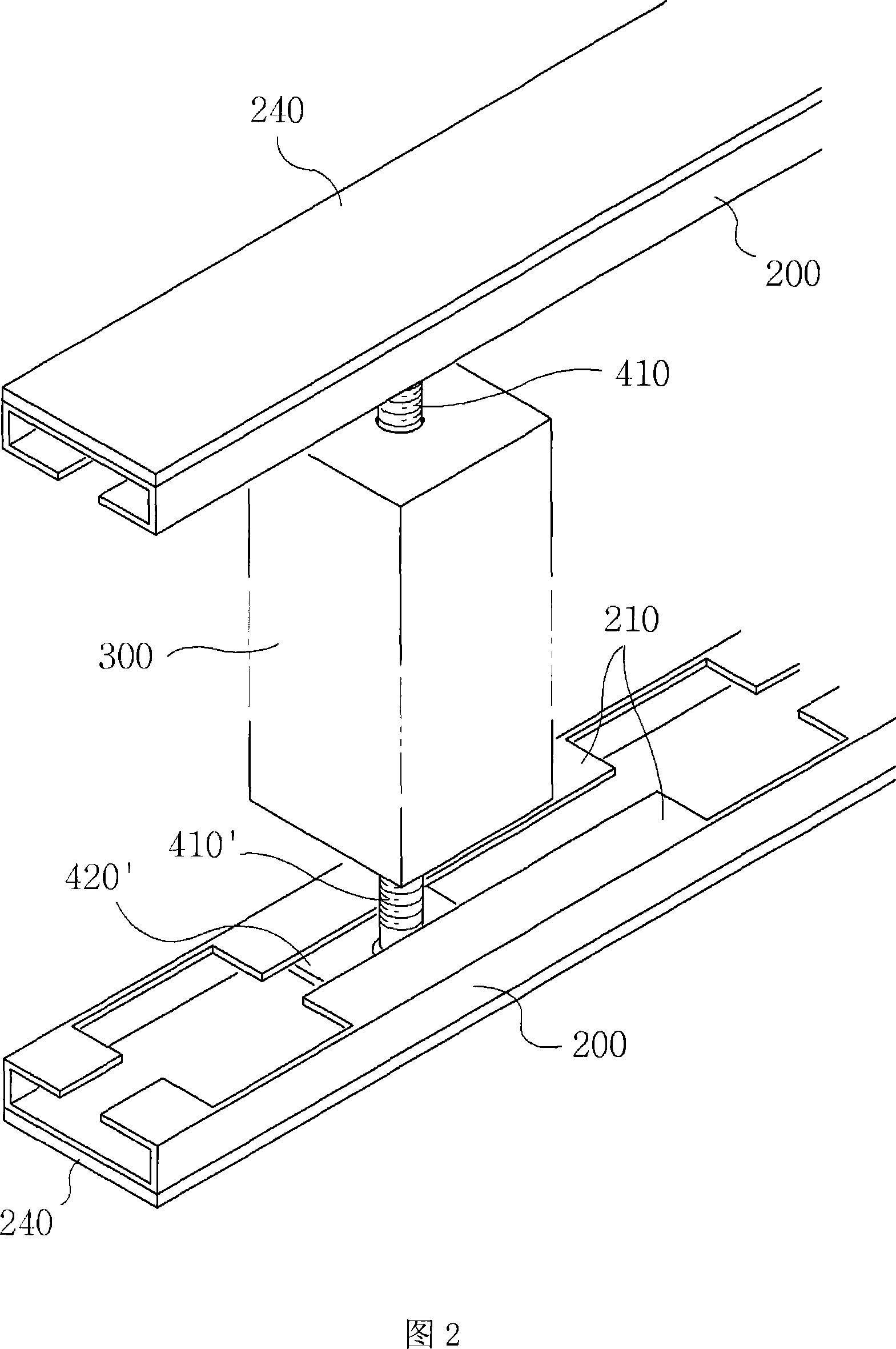

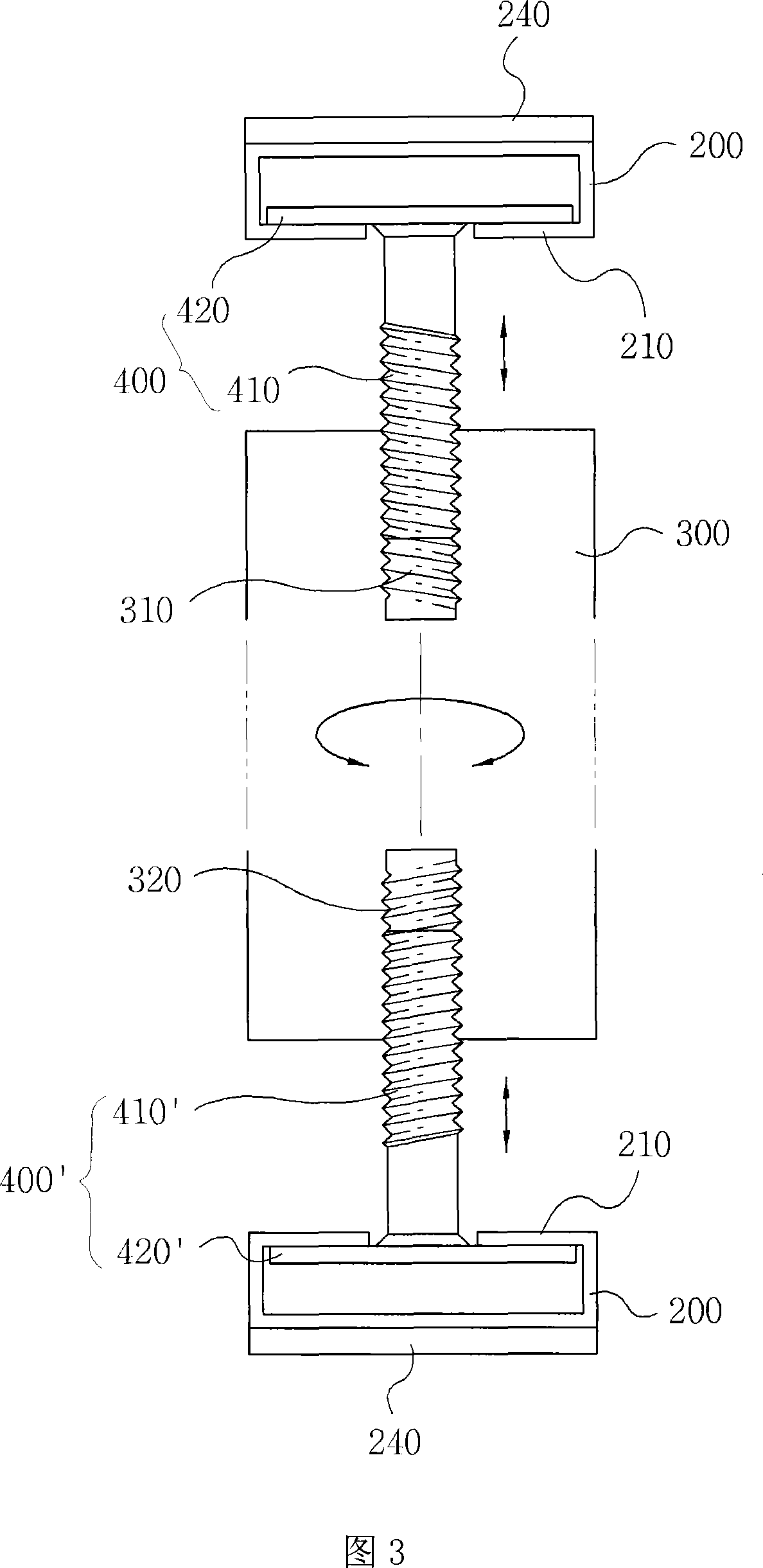

[0022] 1 to 4 are schematic views of the deformable drywall of the present invention.

[0023] As shown in the figure, the deformable drywall 100 of the present invention is mainly composed of a cross sill 200 , a vertical rib 300 , and a board 500 .

[0024] As shown in FIG. 1 and FIG. 2 , the above-mentioned cross sills 200 are fixedly arranged on the top board and the floor respectively.

[0025] Adhesive films 240 are pasted on the side facing the top board and the floor of the above-mentioned cross sill 200 , so that it is pasted and fixed on the top board and the floor.

[0026] In addition, a guide groove 220 cut along the length direction of the cross sill 200 is formed on the facing surfaces of the two cross sills 200 disposed above, and on both sides of the guide groove 220 , along the length of the cross sill 200 The direction is formed with ribs 210 separated by the width of the guide groove 220 .

[0027] In addition, one end of the guide groove 220 of the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com