Active wheel speed sensor tester

A technology of wheel speed sensor and tester, which is applied in the testing/calibration of brakes, speed/acceleration/shock measurement equipment, electronic circuit testing, etc., and can solve the problems that sensors cannot be easily tested

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

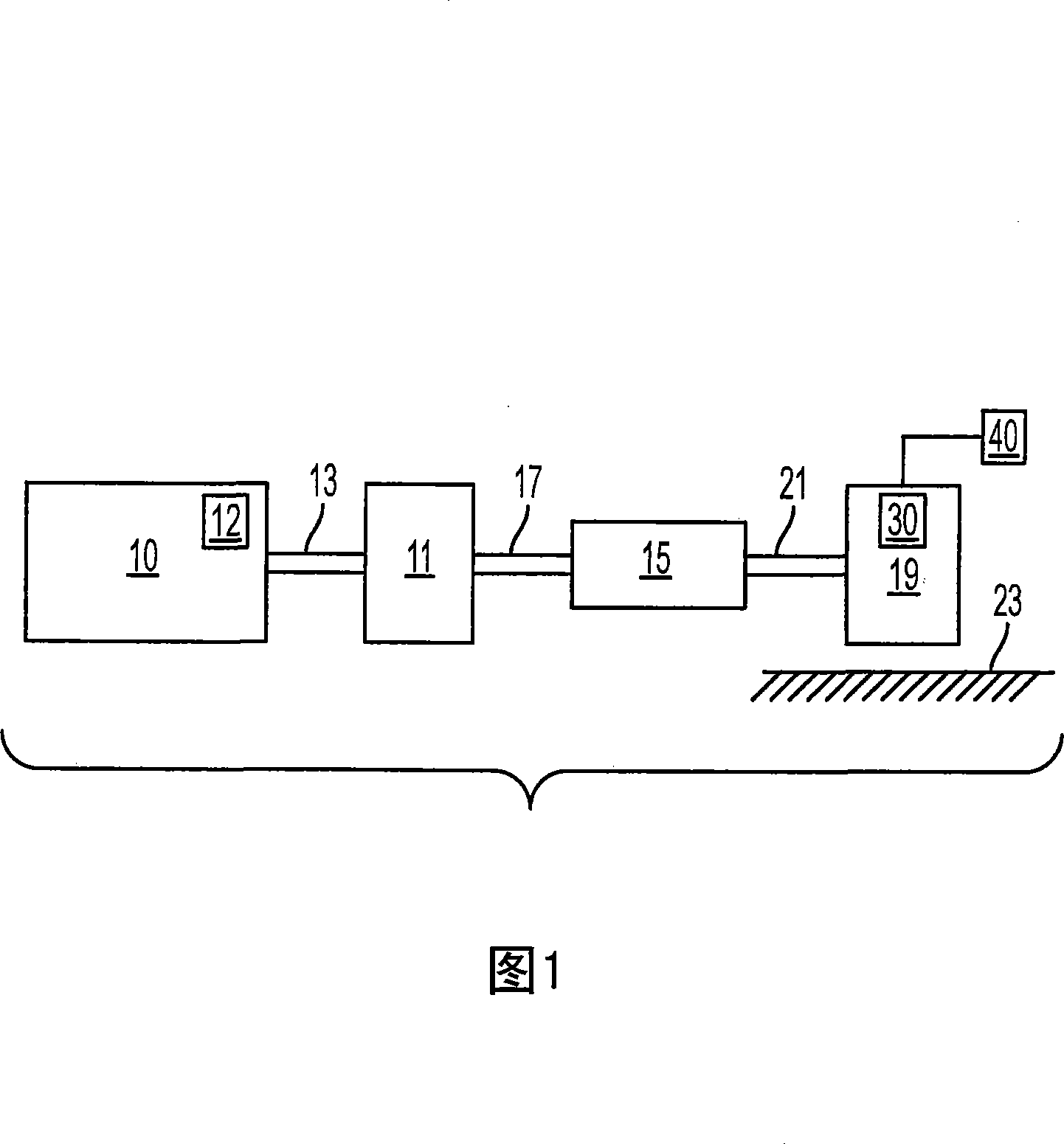

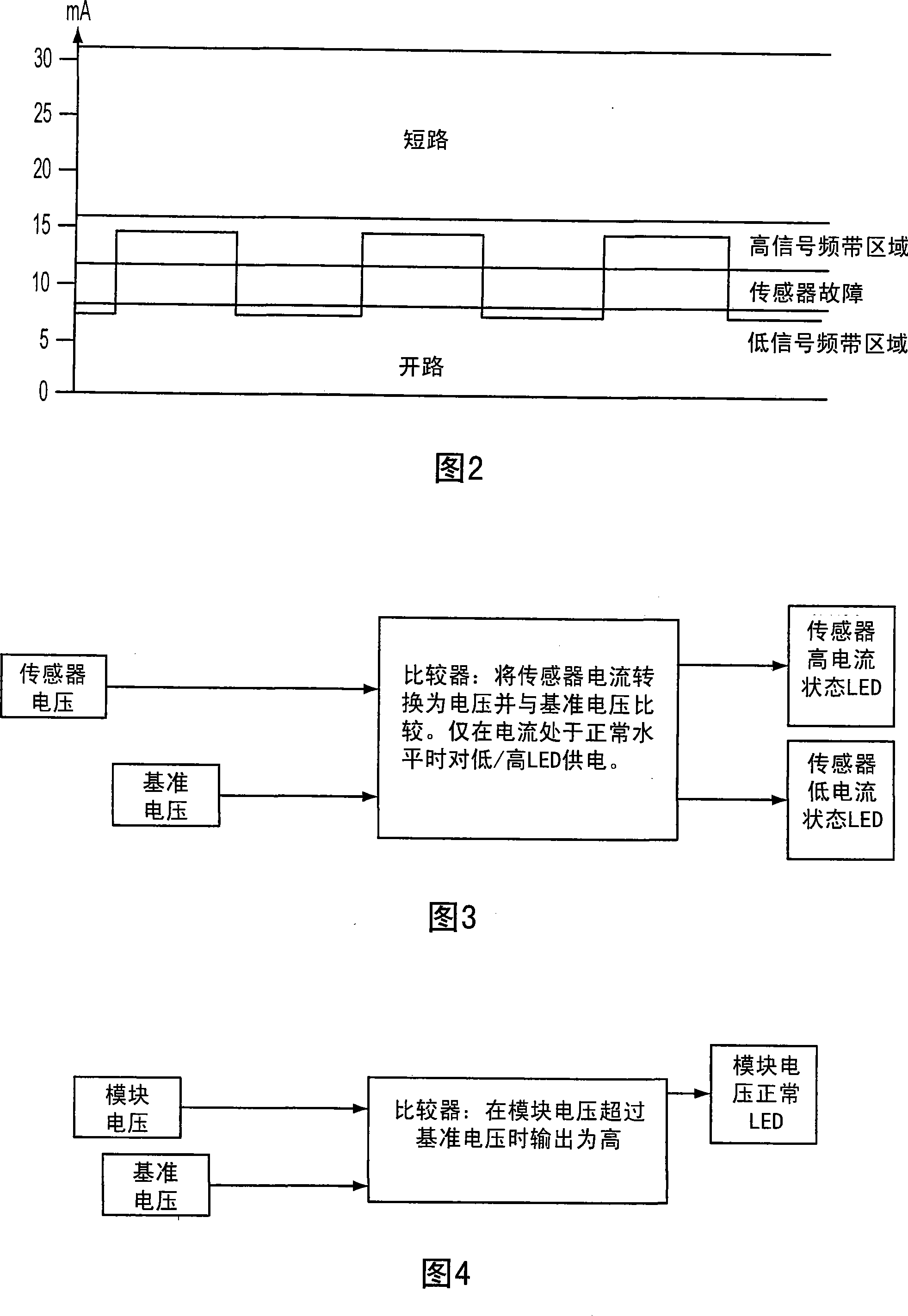

[0017] Active wheel speed sensors can be implemented with integrated circuits and magnets. The integrated circuit may contain a magnetic field responsive component, such as a Hall Effect sensor, that detects changes in the magnetic field passing through the sensing device. Active wheel speed sensors may be located near a rotating toothed tone wheel connected to the axle. As the teeth of the tonewheel pass near the wheel speed sensor, the magnetic field of the magnet distorts. Magnetic field responsive components detect changes in the magnetic field. As a result, the current in the sensor changes. In some embodiments, a sensor may have "low" and "high" states defined by current flow. Electronic control modules in automobiles, such as the anti-lock braking system electronic control module, can monitor the current level in the sensor circuit. Each transition from high to low may involve the passing of a gear tooth, and thus can be used to derive wheel or vehicle speed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com