Tyre bead structure

A technology of bead and bead wire, which is applied in the direction of tires, tire edges, tire parts, etc., can solve problems such as difficulties in manufacturing tires, and achieve the effect of good mechanical retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the description of the drawings, in order to make it easier to understand, similar elements will be denoted by the same reference numerals regardless of their structures or their functions.

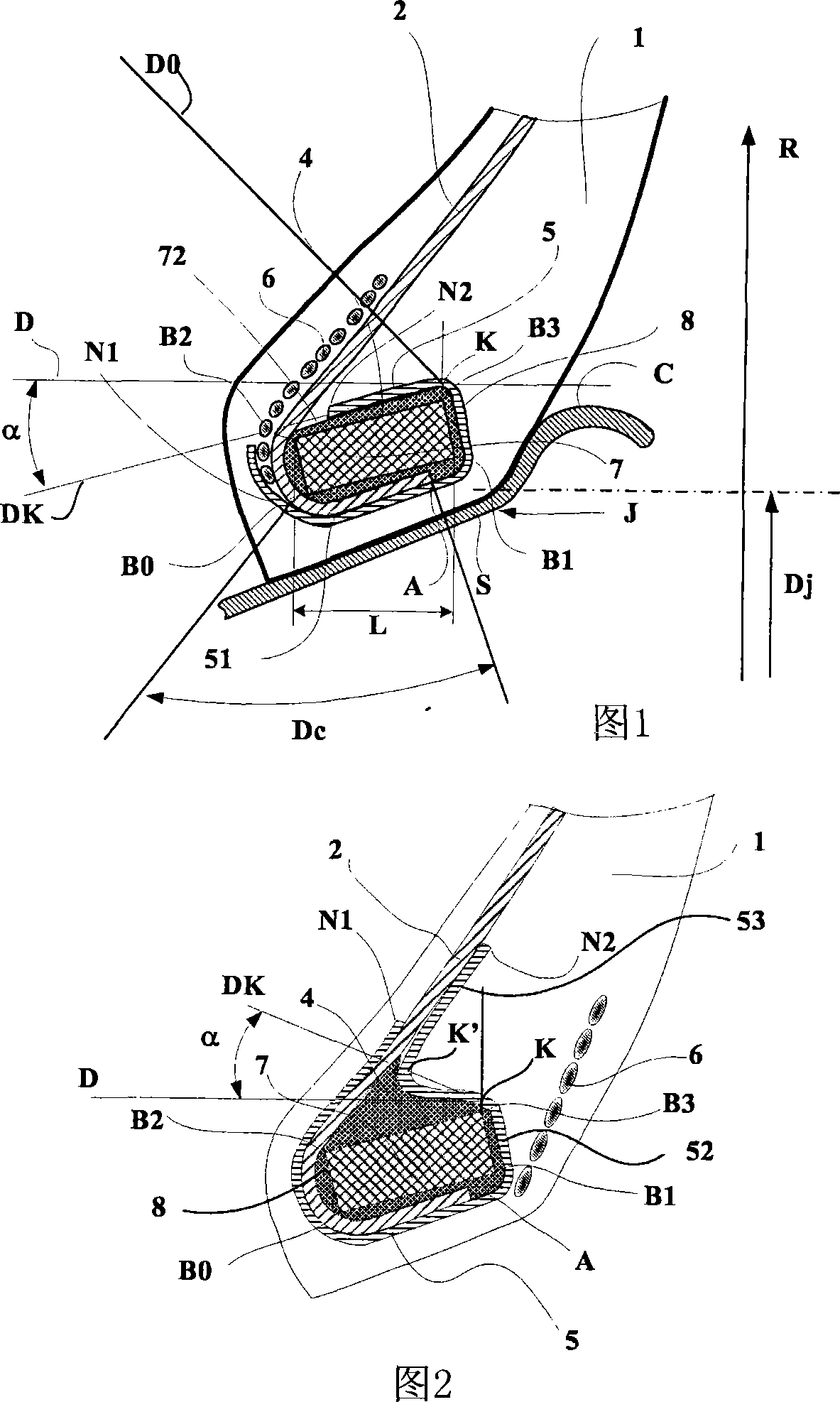

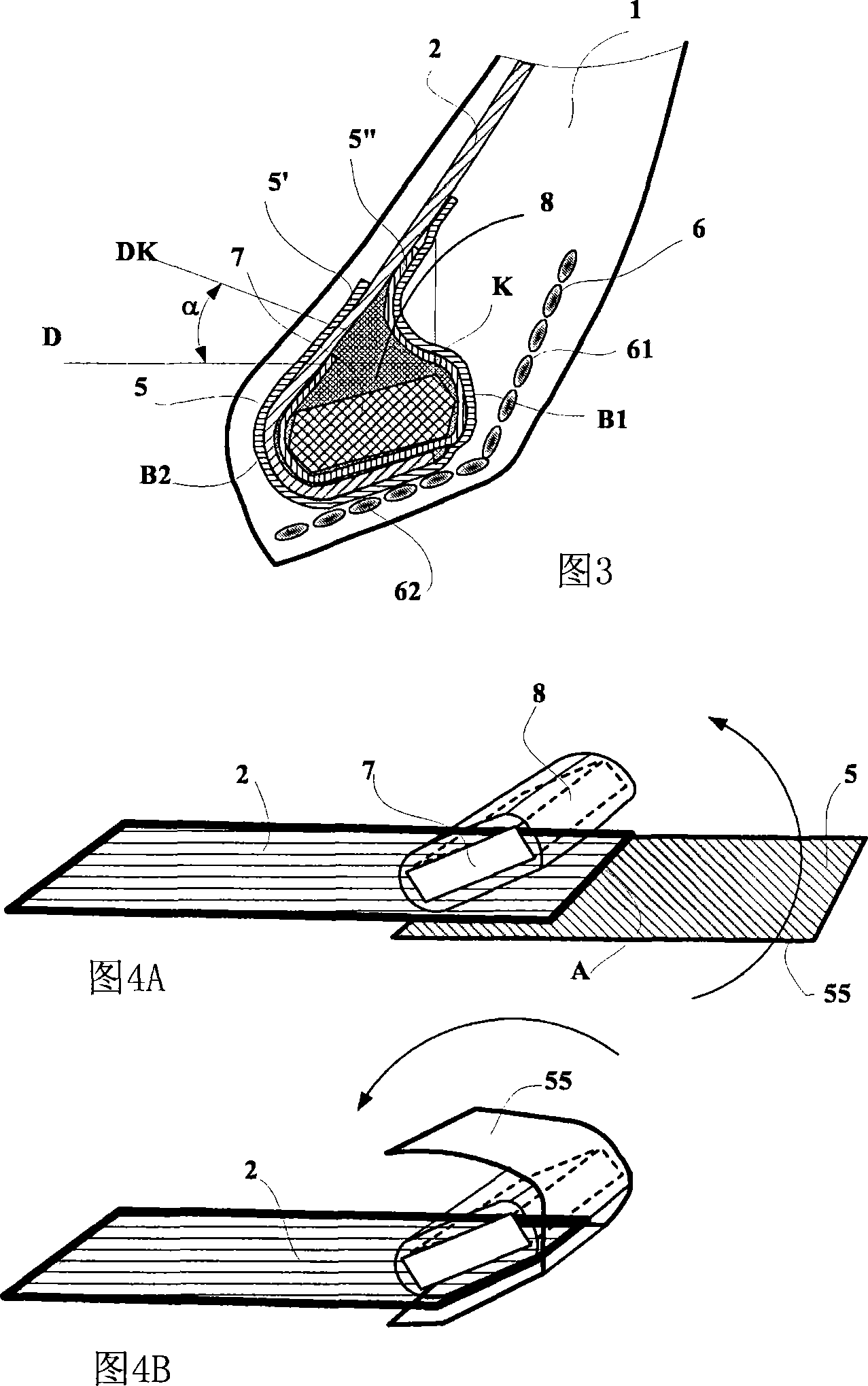

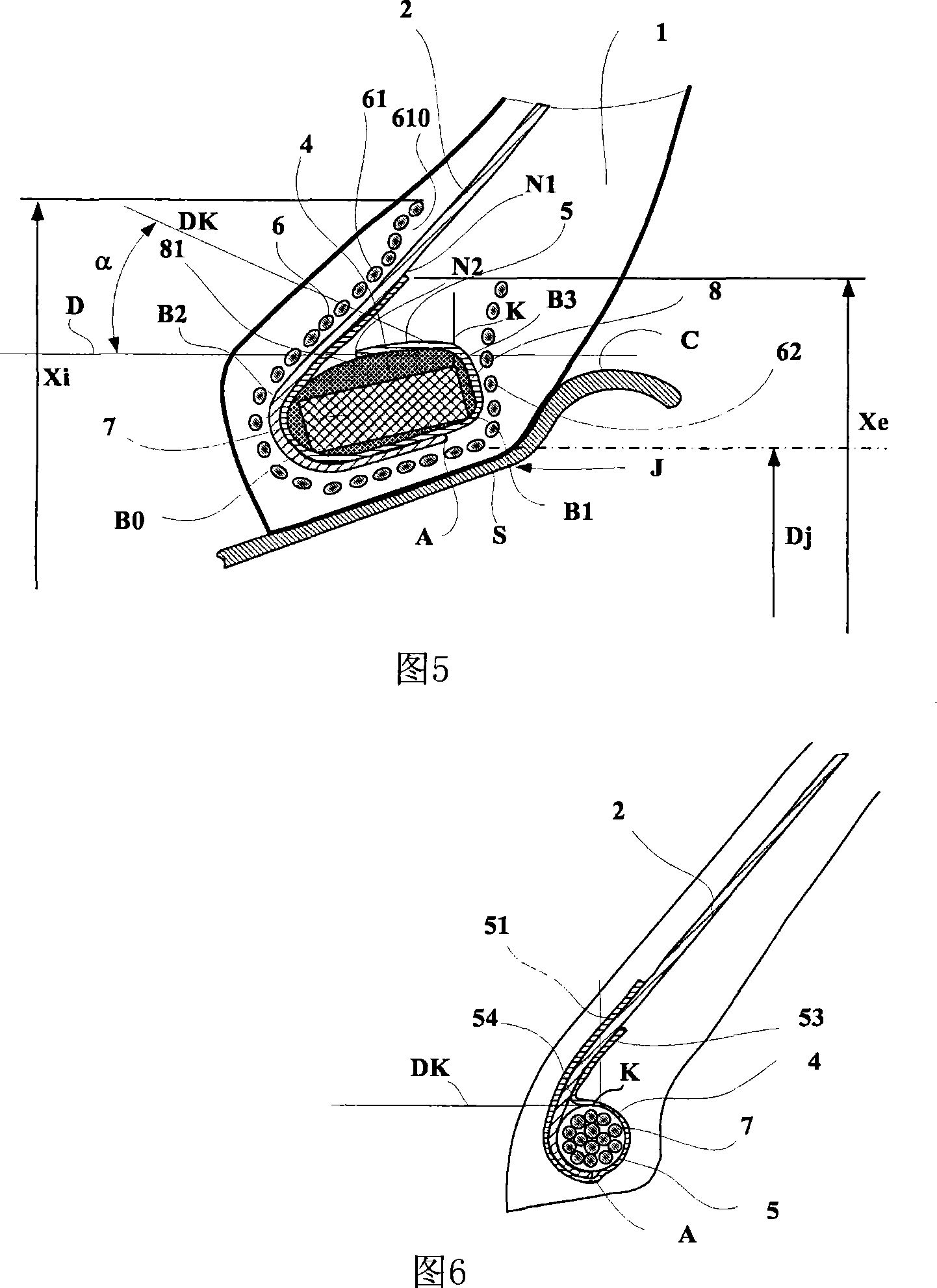

[0038]Figure 1 shows a tire bead 1 according to a first embodiment of the invention. Each bead 1 of this 315 / 60 R 22.5 tire comprises a reinforcement in the form of a metal bead wire 7 formed of a plurality of thin wires wound circumferentially, said bead wire being essentially of Four rectangular sections with vertices B0, B1, B2 and B3 defining four sides. Points B0 and B1 are located on the radially inward side of the cross-section of the bead wire, while points B2 and B3 are located on the radially outward side. Vertex B0 is the radially innermost point (ie, closest to the axis of rotation), and point B3 is the radially outermost point. In this example, the bead wire 7 has an axial width L equal to 20 mm, measured between the points B1 and B2 of the bottom axially furthest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com