Electric capstan

An electric winch and motor technology, which is applied in the directions of portable lifting devices, hoisting devices, clockwork mechanisms, etc., can solve the problems that the electric winch does not have the automatic braking function, cannot automatically brake, and is inconvenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

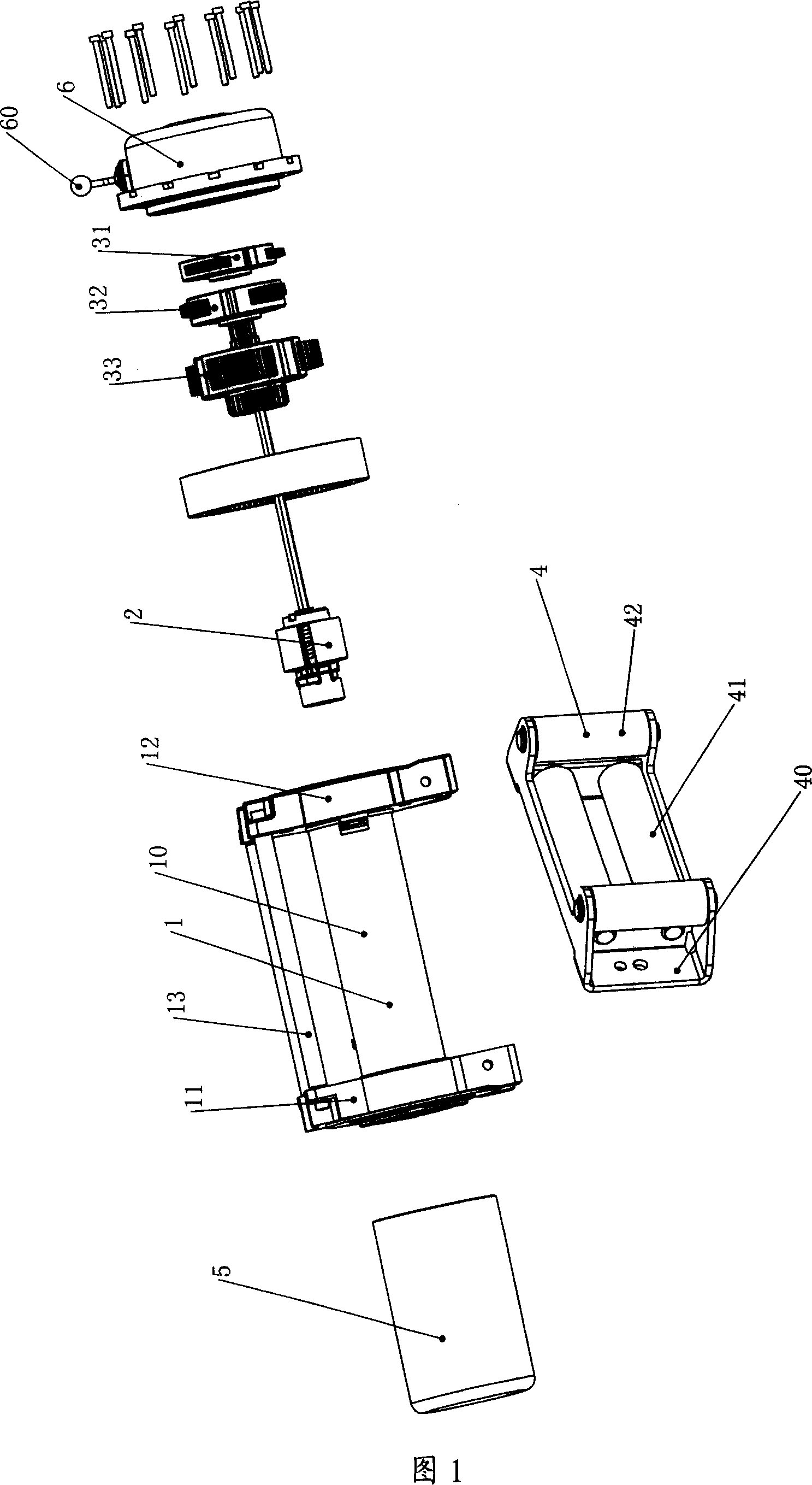

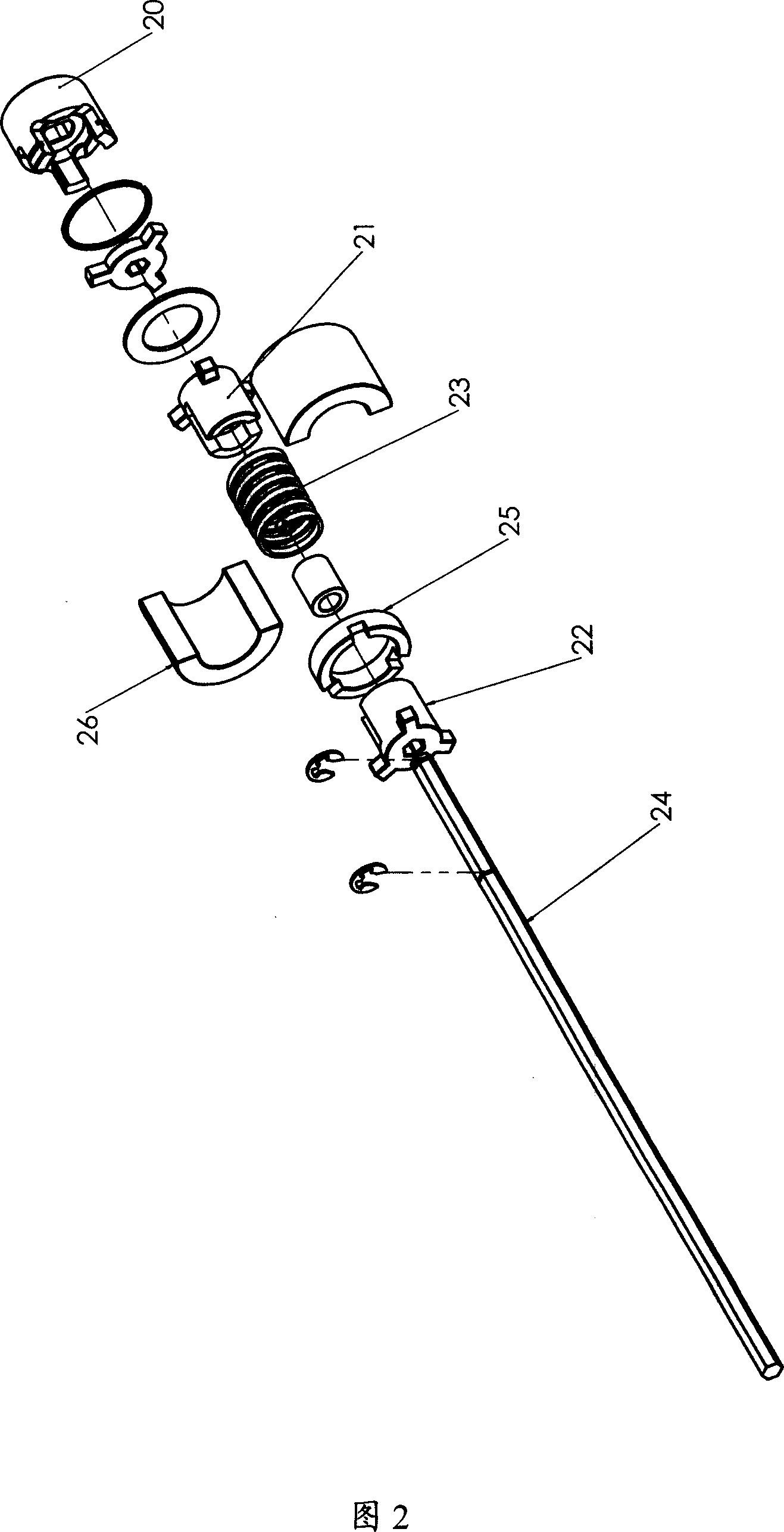

[0020] Please refer to FIG. 1 , the electric winch of the present invention includes a drum unit 1 , an automatic braking unit 2 , a gearbox unit, a cable fairlead 4 and a motor 5 .

[0021] The drum unit 1 is driven by a motor 5, and it includes a drum 10 for winding cables, a front cover 11 positioned at both ends of the drum 10, a rear cover 12, and a connecting rod 13 connected between the front and rear covers 11, 12 . The drum 10 can change the direction of rotation under the control of the remote controller.

[0022] The gearbox unit includes three stages of planetary gears: a first stage planetary gear 31 , a second stage planetary gear 32 and a third stage planetary gear 33 . The three-stage planetary gears are connected successively, and as a transmission mechanism, the energy generated by the motor 5 is converted into a powerful traction force so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com