Continuously variable transmission for bicycle

A technology of continuously variable transmissions and bicycles, applied in vehicle gearboxes, vehicle components, chain/belt transmissions, etc., can solve the problems of step-by-step speed reduction, low mechanical strength, and large friction, etc., to reduce torque mutations, The effect of compact mechanical structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

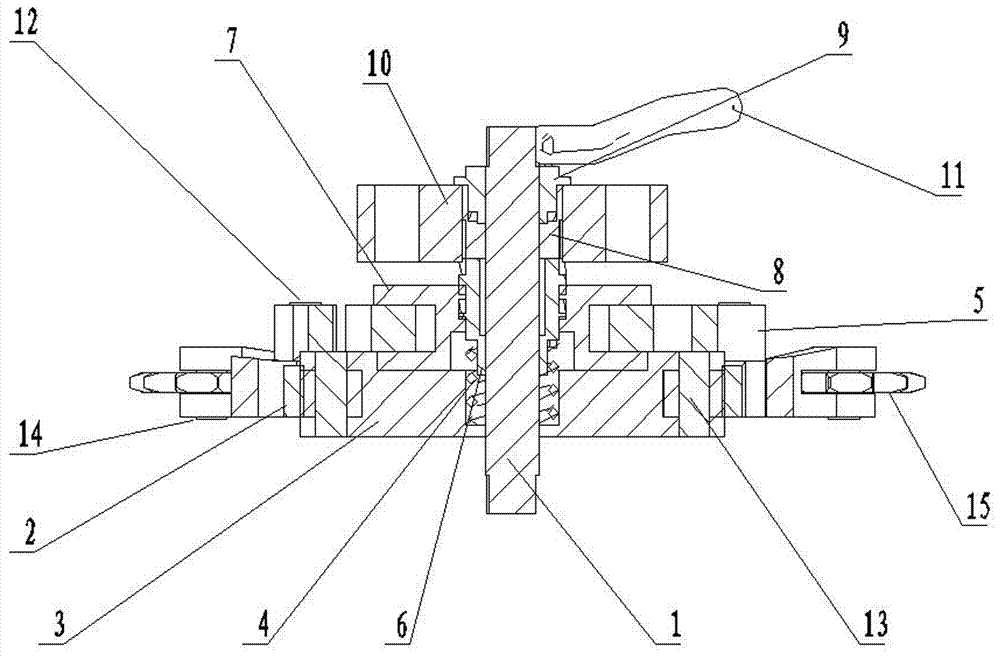

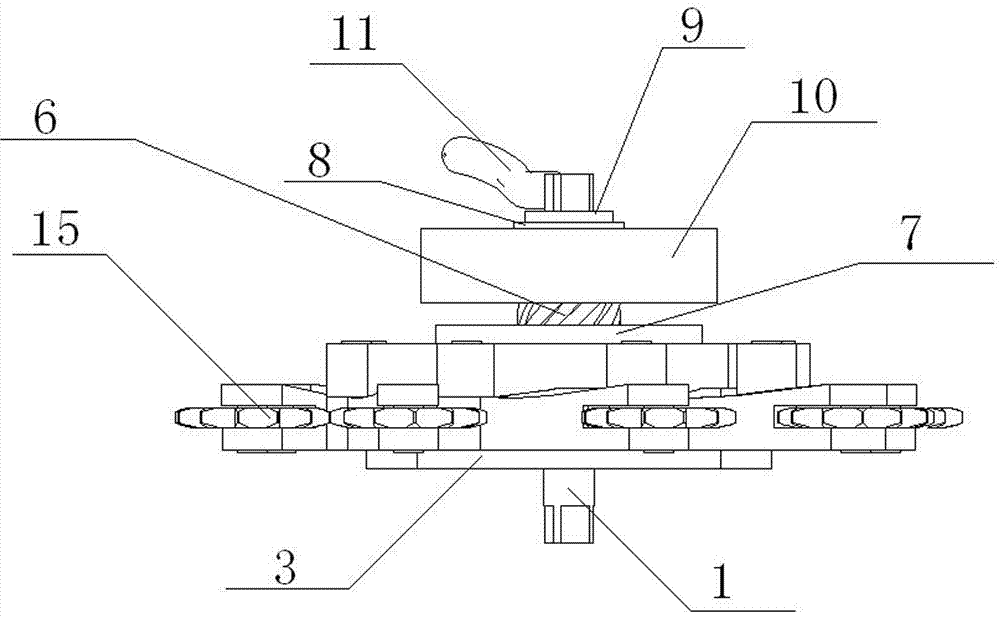

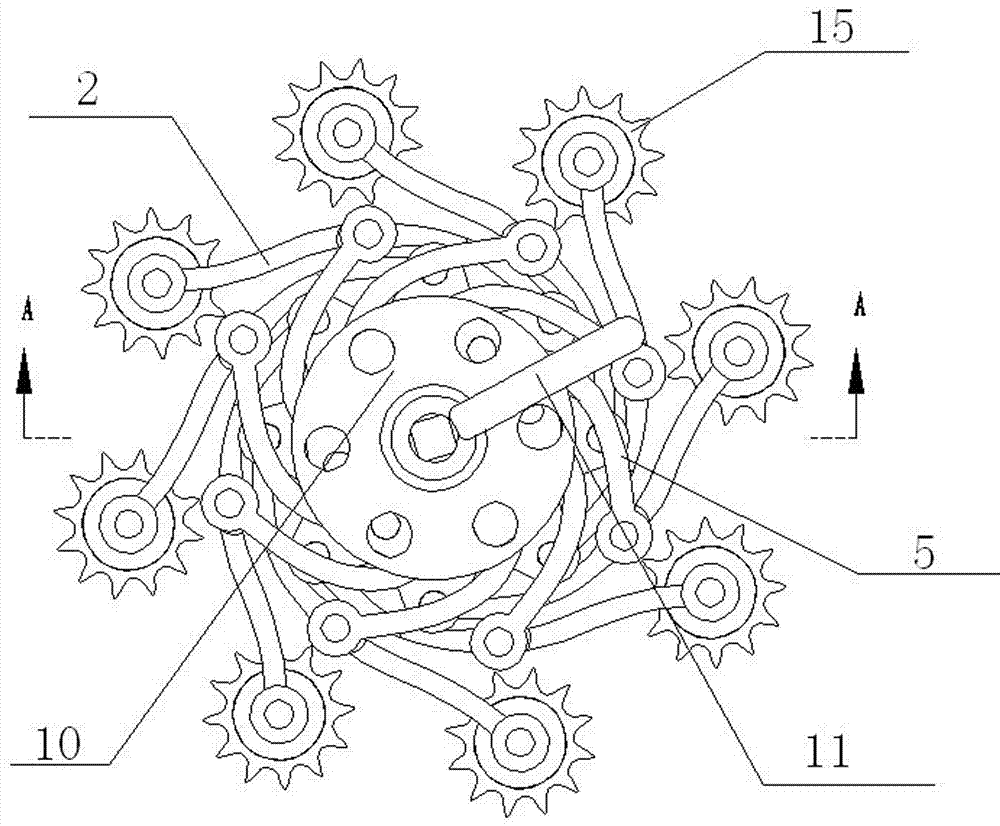

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Such as Figures 1 to 4 As shown, a bicycle continuously variable transmission includes a rotating shaft 1, and the rotating shaft 1 sequentially passes through the circular hole in the center of the first transmission disc 3, the center of the spring 4, the circular hole in the center of the intermediate shaft 6, the first slip The round hole in the center of the gear 8, the round hole in the center of the second sliding gear 9, a spring 4 is arranged in the center hole of the first transmission disc 3, one end of the intermediate shaft 6 touches the spring 4, and the outer wall of the other end passes through Passing through the center of the second transmission disc 7, the other end touches one end of the first sliding gear 8, and the other end of the first sliding gear 8 touches one end of the second sliding gear 9, and the second sliding gear 9 The other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com