Webbing guide mechanism

A guide device and seat belt technology, which is applied in the direction of car seat belts, belt fixing devices, transportation and packaging, etc., can solve laborious problems, achieve large loading/unloading space, improve reliability, and ensure loading/unloading space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

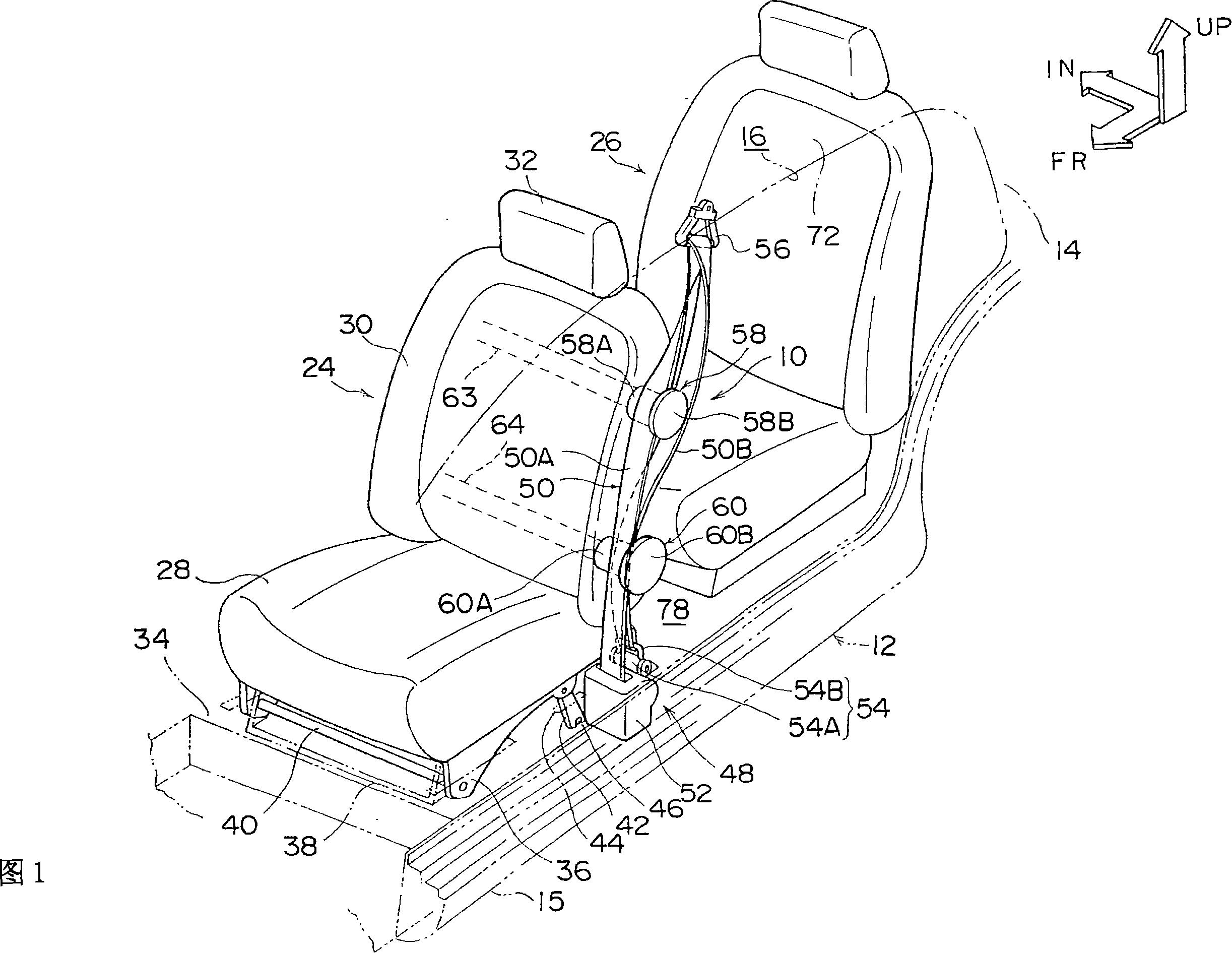

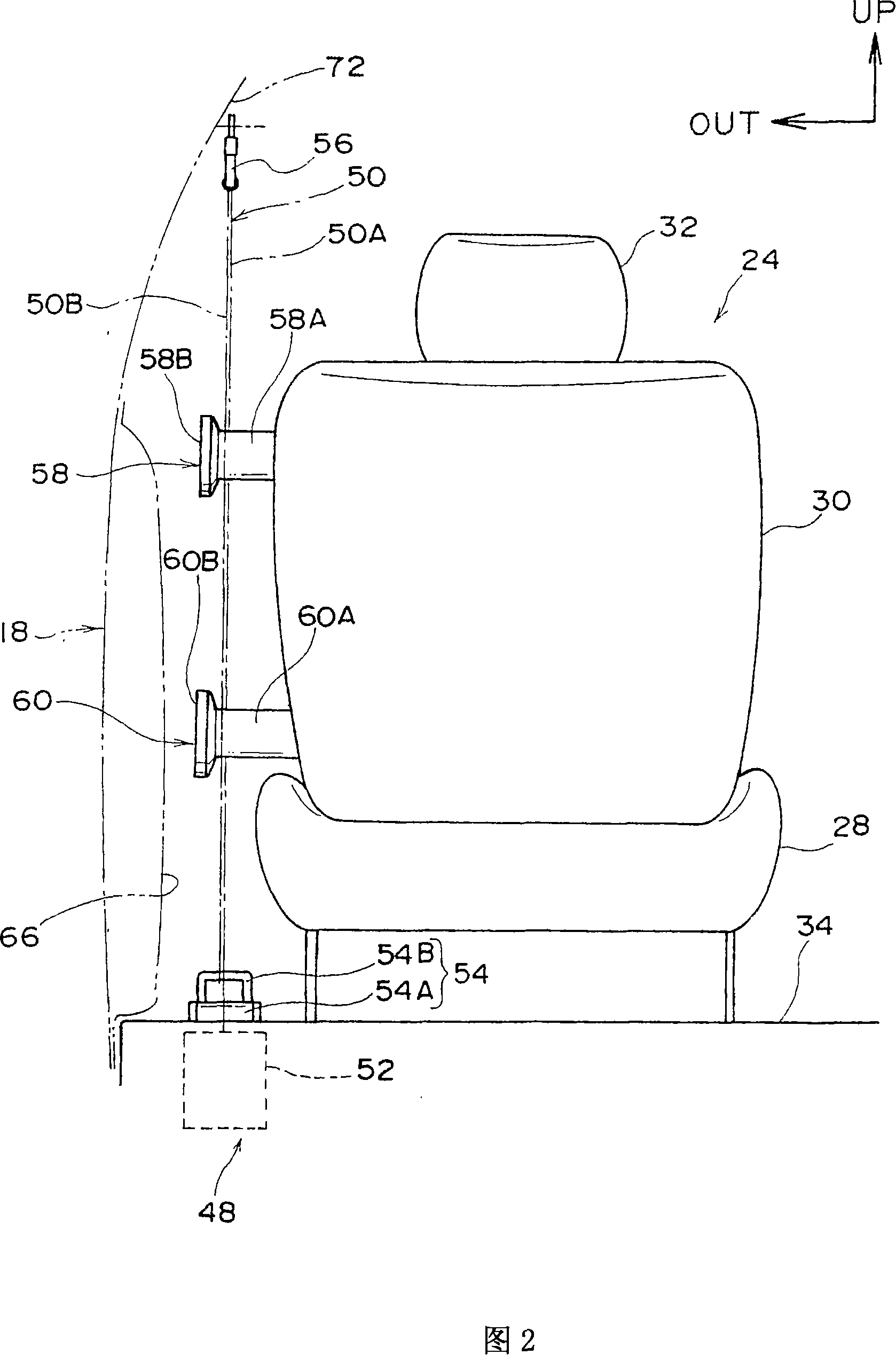

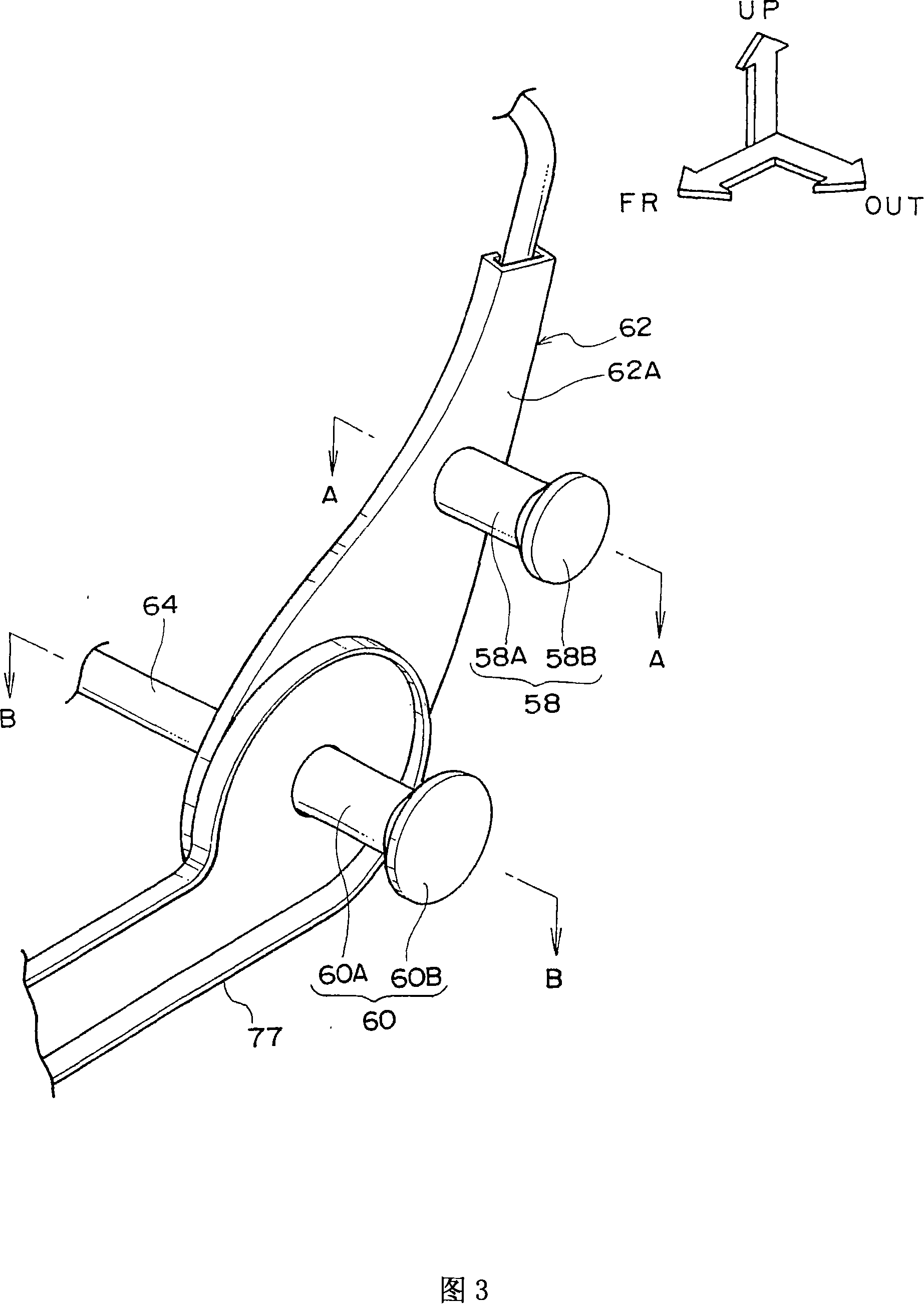

[0048] Next, an embodiment of the seat belt guide device of the present invention will be described with reference to FIGS. 1 to 12 . In the drawings, arrow FR indicates the front side of the vehicle to which the seat belt guide is applied, arrow UP indicates the upper side of the vehicle, arrow IN indicates the inner side of the vehicle in the vehicle width direction, and arrow OUT indicates the outer side of the vehicle in the vehicle width direction .

[0049] FIG. 1 is an external perspective view showing the overall configuration of a seat belt guide 10 of the present invention. As shown in FIG. 1 , a large opening 16 is formed in the body side portion 12 from the front pillar to the rear pillar 14 and between the roof side 72 and the locker 15 , thereby adopting a structure without a center pillar. As shown in FIG. 5 , the "center pillarless structure" refers to a vehicle body structure in which a center pillar connected to the vehicle body is removed and a center pilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com