A built-in mobile phone antenna and its making method

A mobile phone antenna and manufacturing method technology, applied in the directions of printed circuit manufacturing, antenna support/installation device, radiating element structure, etc., can solve the problems of low production efficiency, high cost, unadjusted hot-melt temperature, etc. Production cost, the effect of improving production capacity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

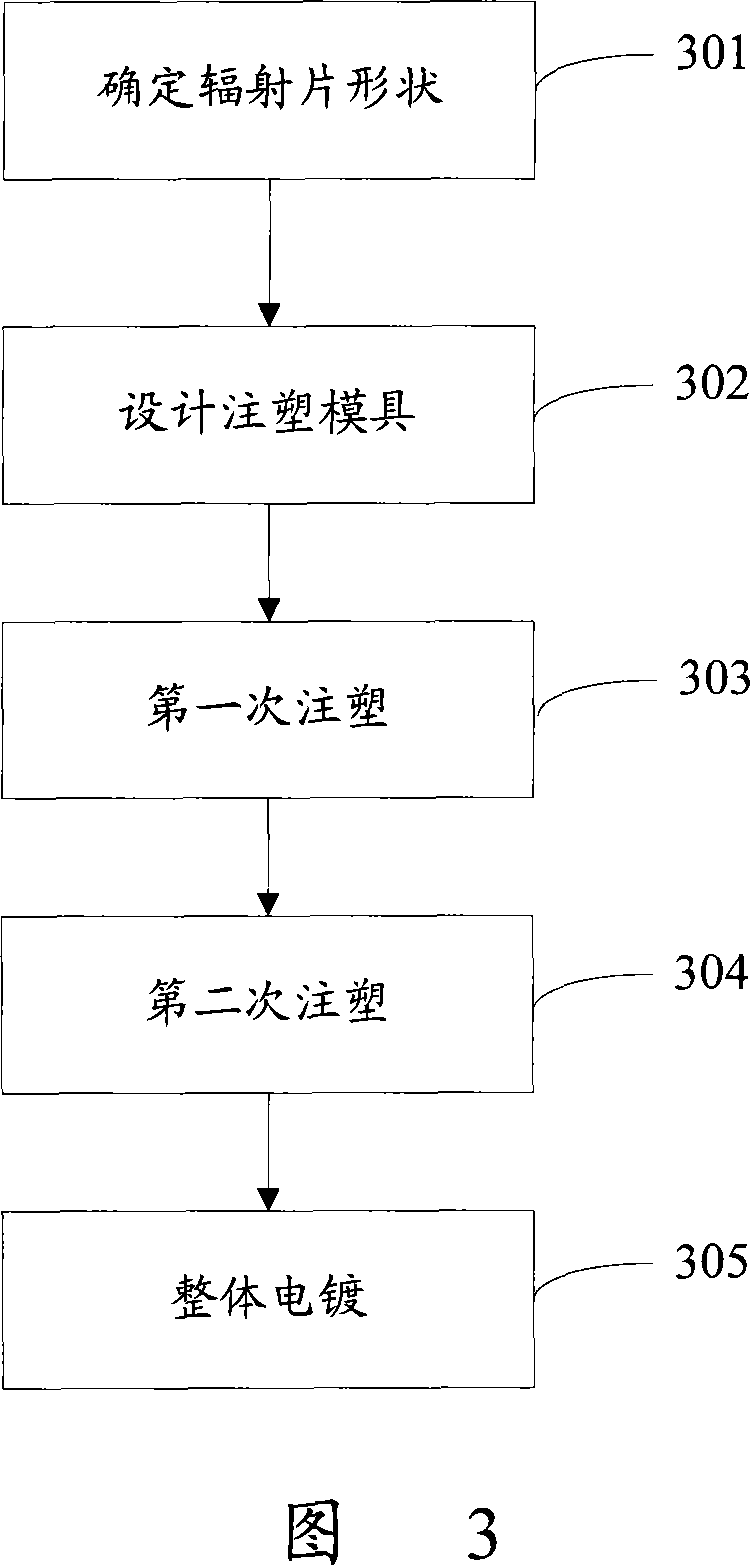

[0024] The core idea of the present invention is: the bracket part of the built-in mobile phone antenna is injection-molded by PC material, the radiator part is molded by secondary injection molding of ABS material, and then the whole built-in mobile phone antenna is electroplated to form a metal radiation piece of a specific shape.

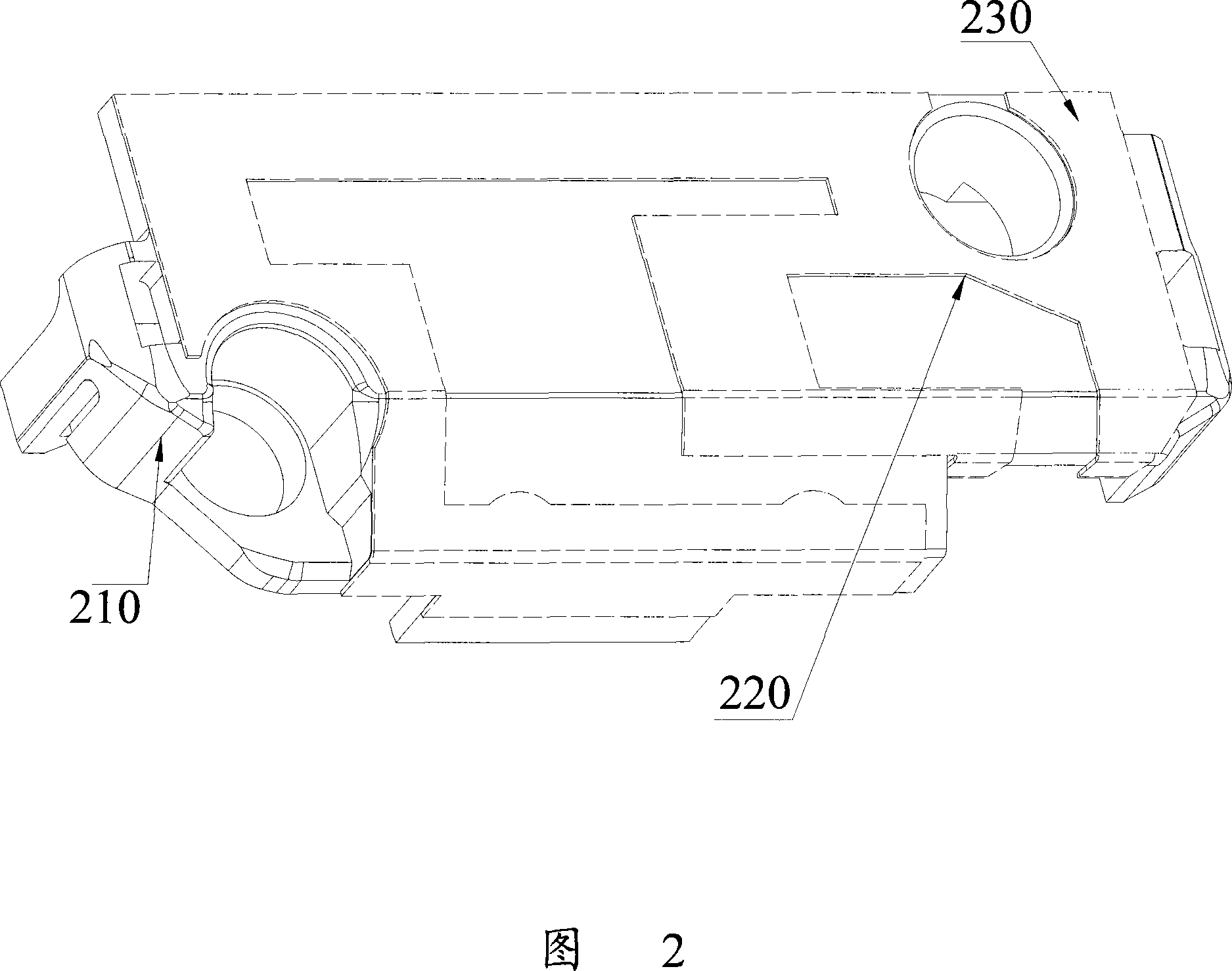

[0025] Fig. 2 is the structural representation of built-in mobile phone antenna among the present invention, and as shown in Fig. 2, antenna is made up of bracket part 210, radiation sheet part 220 and radiation sheet part coating 230, and wherein, the material of bracket part 210 is non-electroplateable material, It can be PC, or other non-platable materials that can be used as a built-in mobile phone antenna bracket material, such as nylon; the material of the radiator part 220 is an electroplatable material, which can be ABS, or other materials that can be used as a built-in mobile phone antenna bracket Electroplatable material of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com