Method for mounting seabed anchor

An installation method and technology of anchor barrels, which are applied in the direction of anchor points, transportation and packaging, ship parts, etc., can solve the problems of small insertion depth, loss of anchoring effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

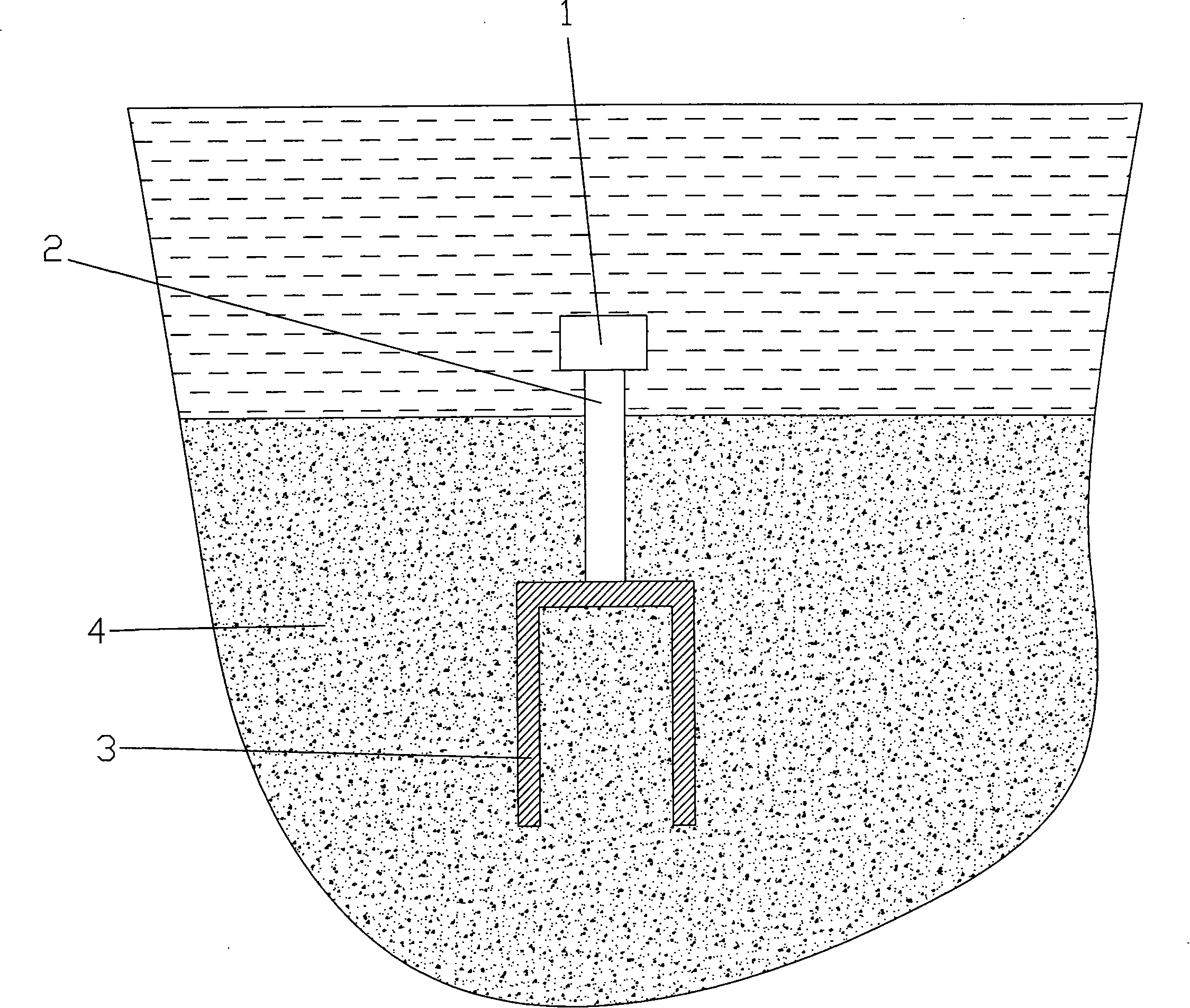

[0010] As shown in the drawings, according to the method of the present invention, when carrying out the anchoring operation of the seabed anchor, at first the mechanical vibration device 1 is installed on the top of the anchor tube 3 through the strut 2, and the length of the strut 2 and the top of the anchor tube 3 are submerged in the seabed soil. Then, the anchor cylinder 3 is automatically inserted into the seabed soil 4 by using the mechanical vibration generated by the mechanical vibration device and the self-weight of the anchor cylinder.

[0011] During the insertion process of the anchor tube 3 into the soil body 4, the soil around the anchor tube 3 will continue to soften and even liquefy with the vibration, and the anchor tube 3 will continuously discharge the softened soil around it to the outside under the action of its own weight , and gradually penetrate deep into the soil.

[0012] Since the present invention utilizes the feature that the soil body will soften...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com