Lens module

A technology for lens modules and mirror holders, applied in installation, optics, instruments, etc., can solve problems such as poor adhesion, shedding of optical filters 13, incomplete curing of viscose UV glue, etc., so as to improve production yield and avoid The effect of dispensing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

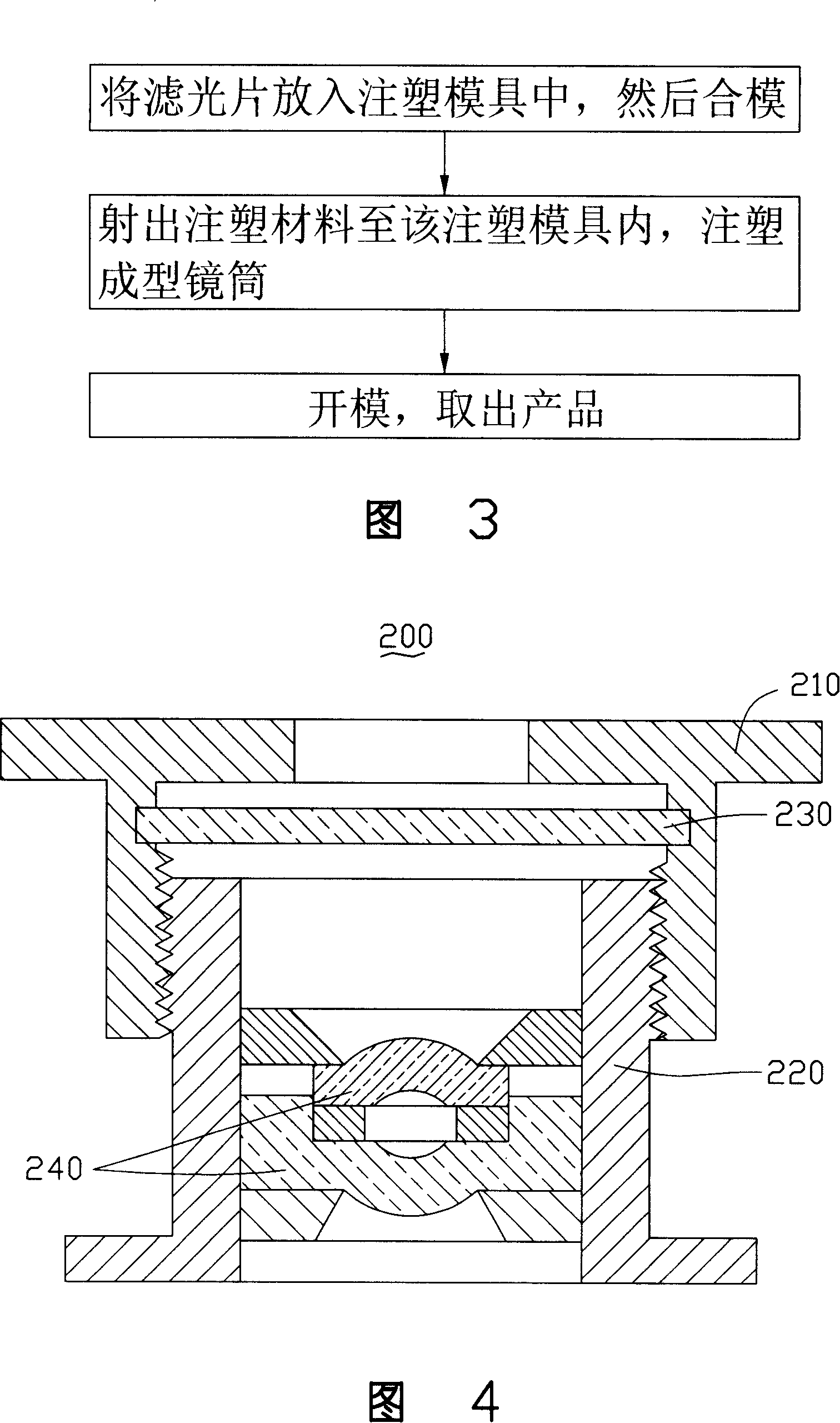

[0014] Please refer to FIG. 2 , the lens module 100 in the first embodiment of the present invention includes a lens base 110 , a lens barrel 120 matched with the lens base 110 , and a filter 130 and a lens group 140 accommodated in the lens barrel 120 , The filter 130 is integrally formed with the lens barrel 120 . Said fit is a fixed connection or a threaded connection, in this embodiment, a threaded connection.

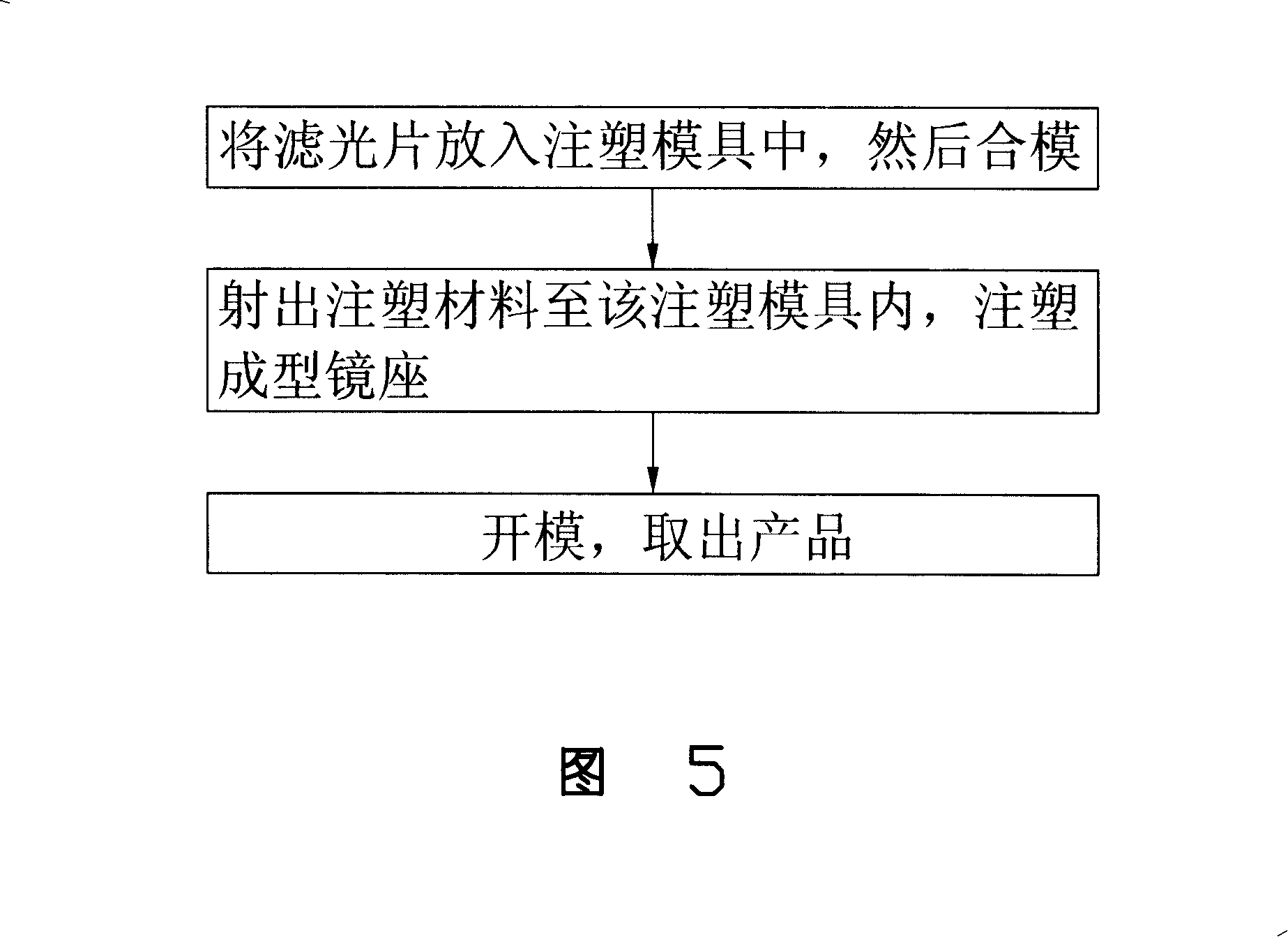

[0015] The optical filter 130 and the lens barrel 120 can be integrally formed by in-mold molding technology (Insert Molding), please refer to FIG. 3 , the integral molding method mainly includes the following steps:

[0016] Put the filter 130 into the injection mold, and then close the mold;

[0017] Injecting plastic material into the injection mold, injection molding the lens barrel 120;

[0018] Open the mold, take out the product, and obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com