Method for detecting lens module performance

A lens module and lens detection technology, which is applied in optics, instruments, photography, etc., can solve problems such as no image, damage to the light range of the outgoing lens module, and out-of-range light range of the incident lens module, so as to achieve small space and avoid Assembling defective products and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for detecting the performance of the lens module provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

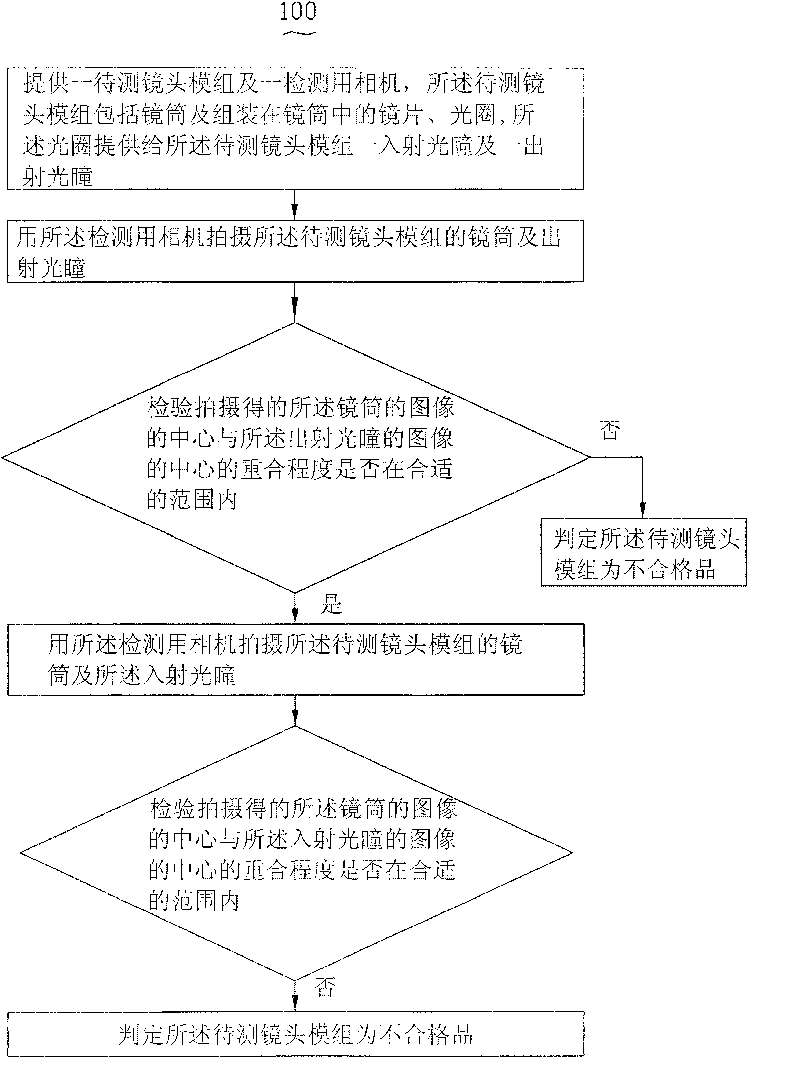

[0024] Please also refer to Figure 1 to Figure 3 The method 100 for detecting the performance of the lens module provided by the first embodiment of the present invention includes the following steps:

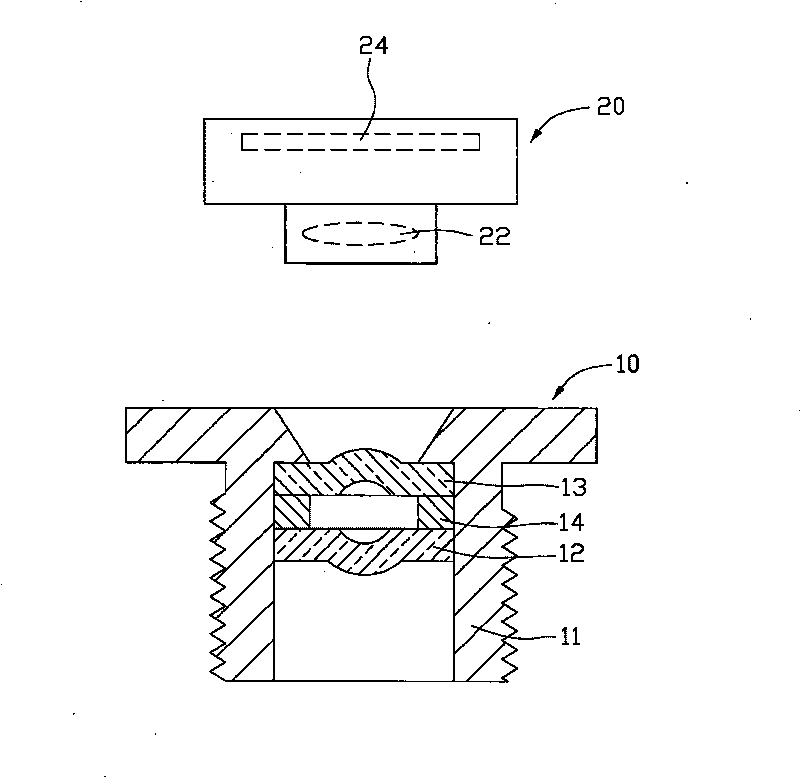

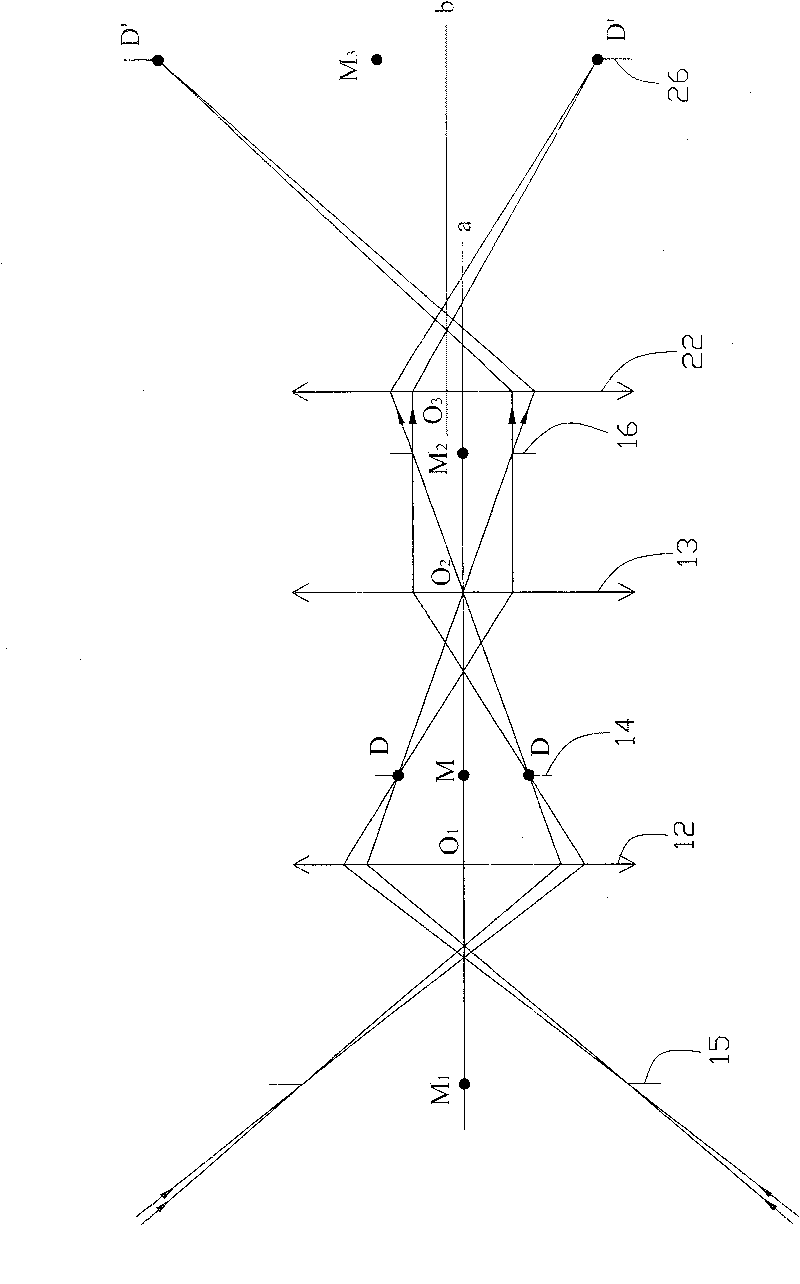

[0025] (1) Provide a lens module 10 to be tested and a camera 20 for detection, the lens module 10 to be tested includes a lens barrel 11, two lenses assembled in the lens barrel 11 in sequence from the object side to the image side 12, 13, and an aperture 14 sandwiched between the eyeglasses 12, 13, the aperture 14 forms an entrance pupil 15 on the object side of the lens module 10 to be tested through the eyeglass 12, through The lens 13 forms an exit pupil 16 on the image side of the lens module 10 to be tested;

[0026] (2) photographing the lens barrel 11 and the exit pupil 16 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com