Ultrasound motor drive controller based on built-in system chip

A drive controller, embedded system technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems that hinder the promotion of ultrasonic motors, and achieve stable motors The effect of speed and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

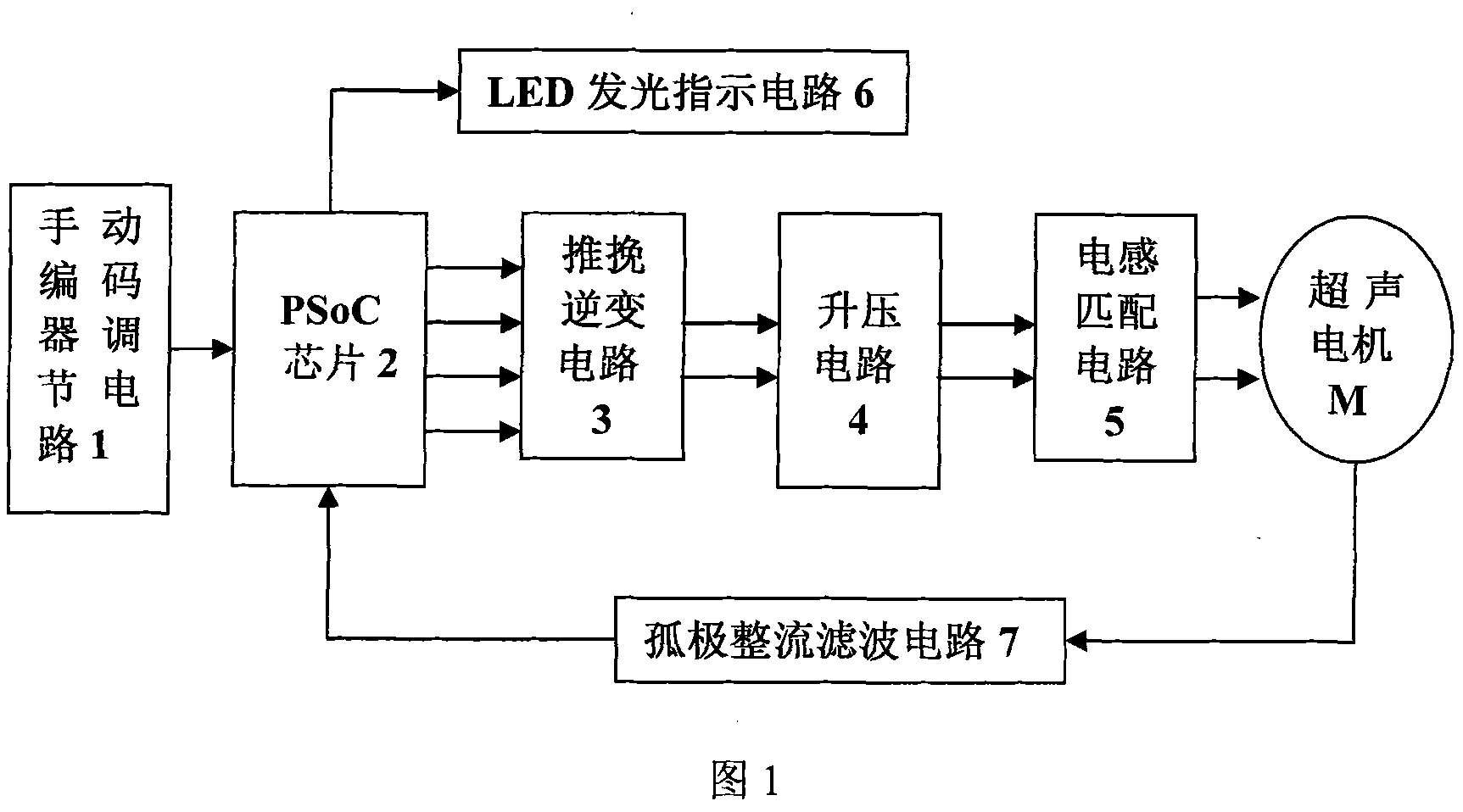

[0021] The ultrasonic motor drive controller based on the embedded system level chip of the present invention, such as figure 1 As shown, it includes a manual encoder adjustment circuit 1, a PSoC chip 2, a push-pull inverter circuit 3, a boost circuit 4, an inductance matching circuit 5, an LED light-emitting indication circuit 6, and an isolated pole rectification filter circuit 7, wherein the manual encoder The regulating circuit 1 is connected to the input terminal of the PSoC chip 2, the output terminal of the PSoC chip 2 is respectively connected to the input terminal of the LED light-emitting indicating circuit 6, the input terminal of the push-pull inverter circuit 3, and the output terminal of the push-pull inverter circuit 3 is connected to the boost voltage The input terminal of the circuit 4, the output terminal of the boost circuit 4 are connected to the input terminal of the inductance matching circuit 5, the output terminal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com