Paper or board machine

A technology of cardboard machine and paper machine, applied in the direction of paper machine, paper machine, paper machine wet end, etc., can solve the problem of extending the installation schedule of paper machine or cardboard machine, so as to shorten the total time, reduce restrictions, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

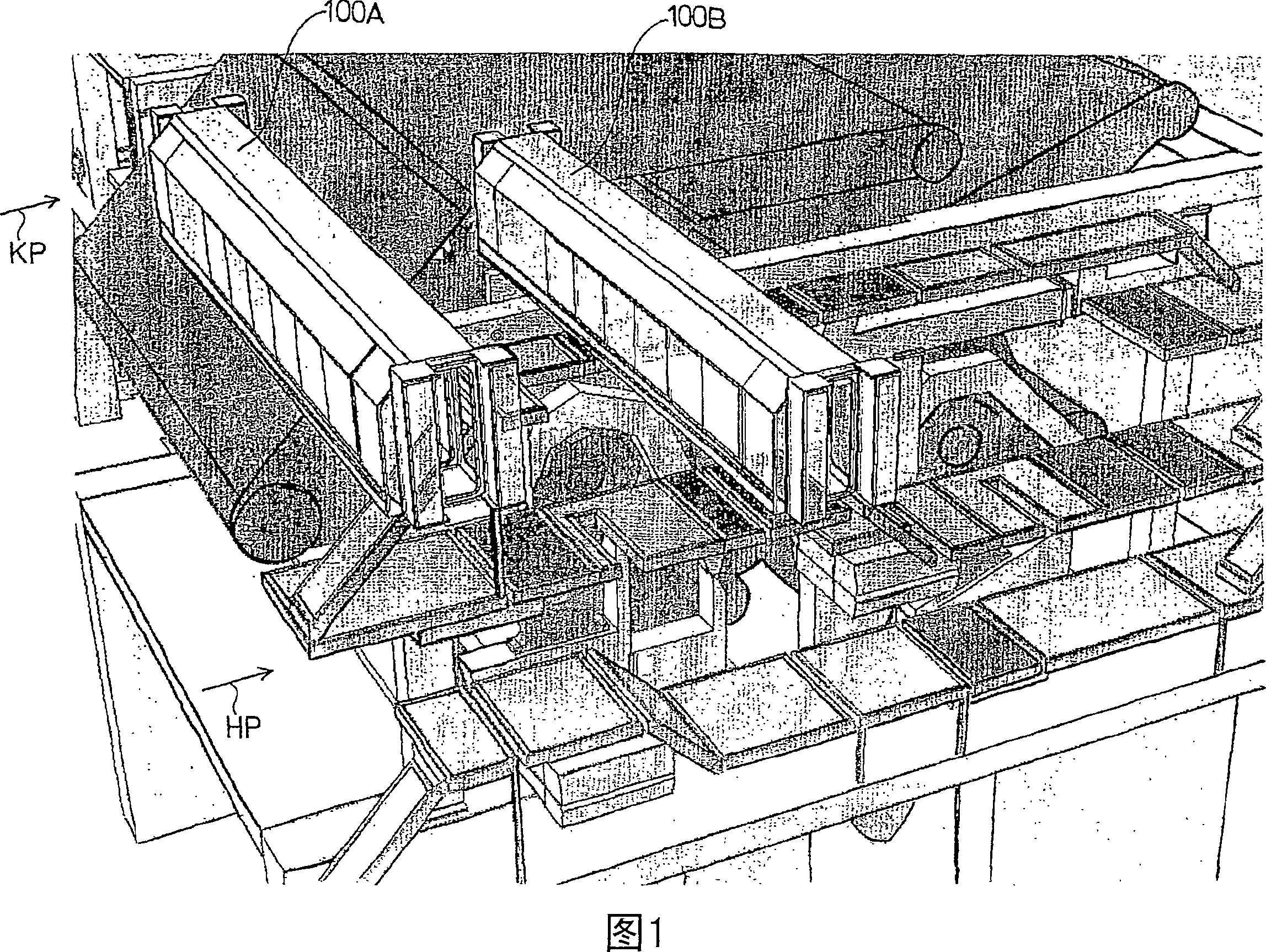

[0023] Figure 1 schematically shows the press section of a paper machine and two closed passage spaces 100A, 100B extending from the operating side HP of the machine to the driving side KP of the machine.

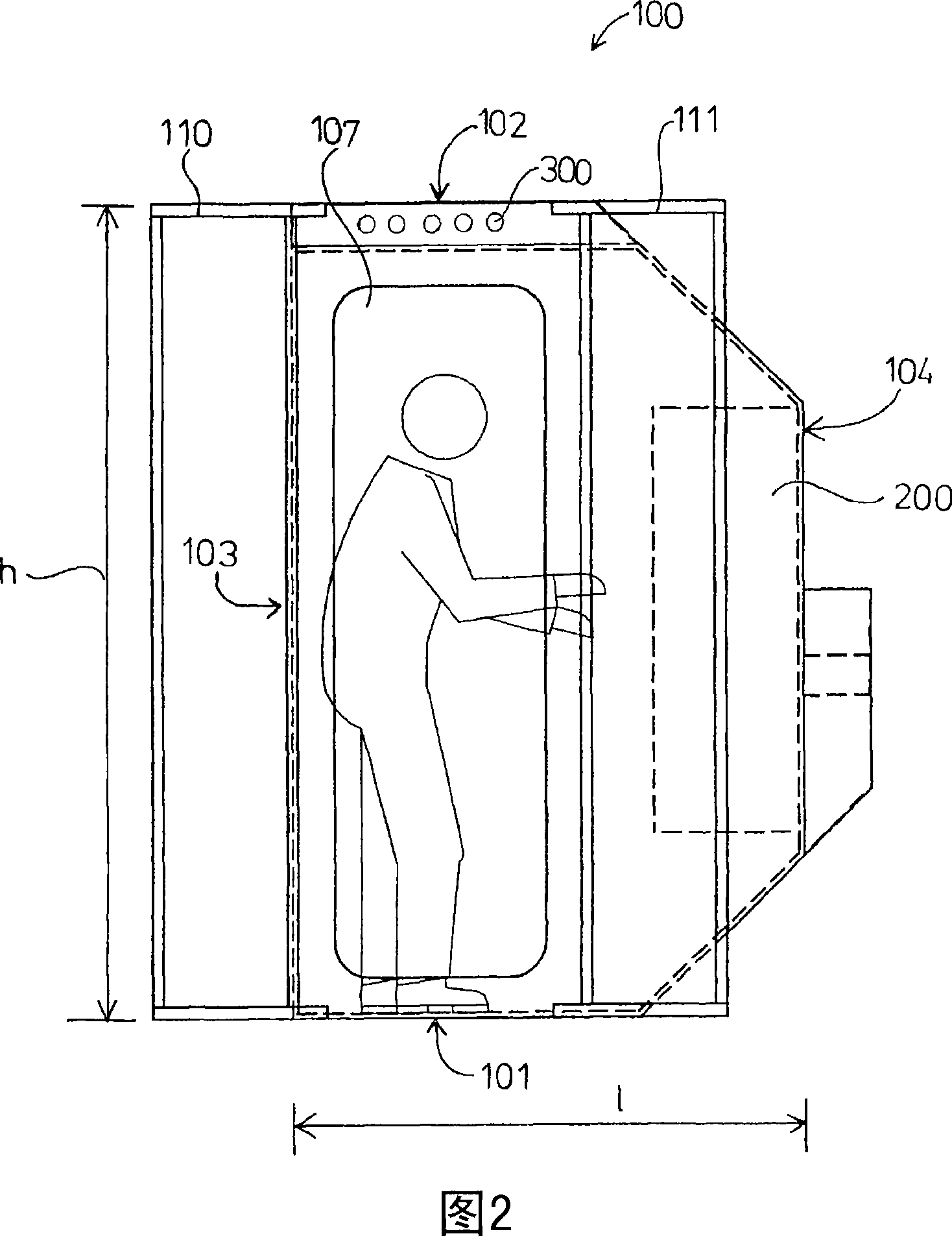

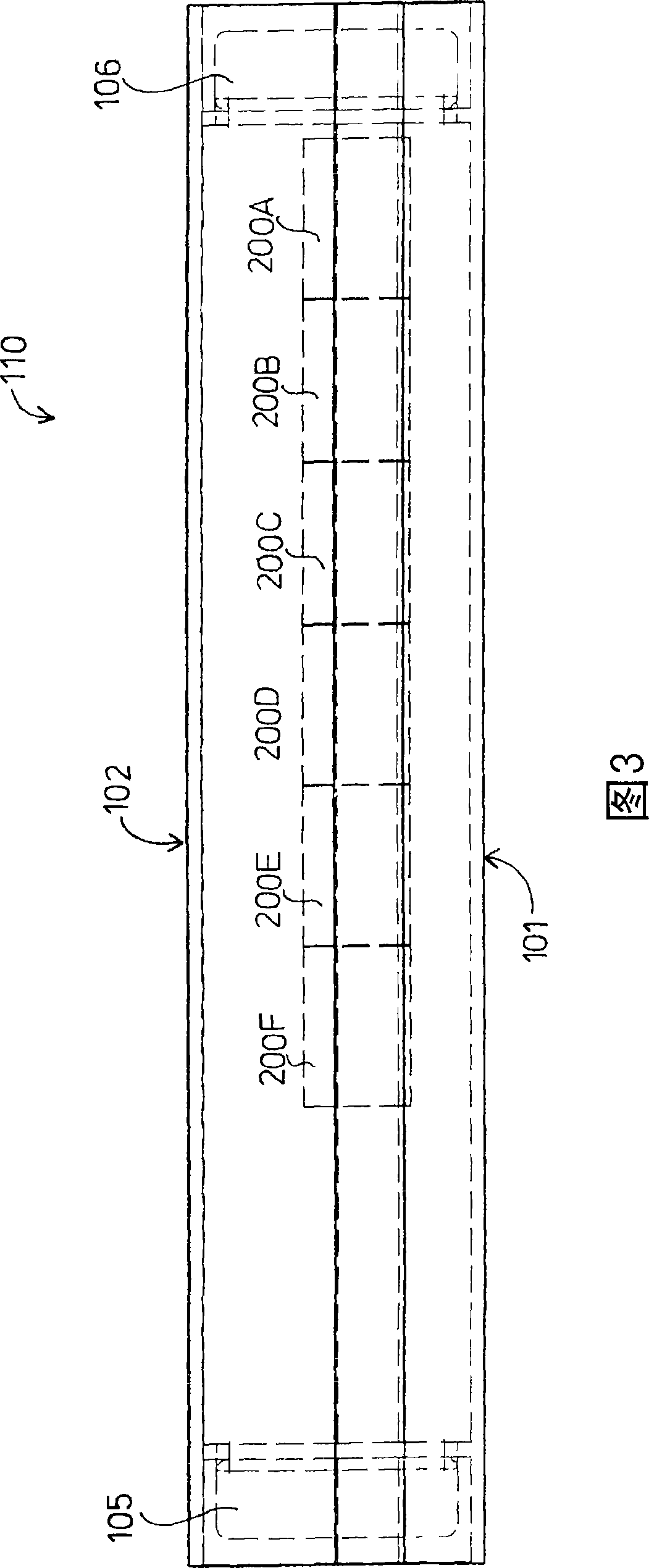

[0024] FIG. 2 is a cross-sectional view of the channel space 100 shown in FIG. 1 , and FIG. 3 is a longitudinal sectional view of the channel space 100 shown in FIG. 1 . The passage space 100 includes: a floor surface 101 , a ceiling surface 102 , a first side wall 103 , and a second side wall 104 . The vertical trapezoidal shape of the second side wall 104 is primarily determined by the space available at the installation location. The boxes 200A...200F are attached to the second side wall 104 of the passage space 100, and automatic equipment can be arranged in said boxes. The height h of the passage space 100 is formed such that an operator can walk upright in the space. The width 1 of the passage space in the longitudinal direction is instead formed such that the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com