A artificial scalp surface layer non hair buckled hairpiece and its preparation method

A manufacturing method and hair technology, applied in wigs, bald wigs, hair accessories, etc., can solve the problems of lack of beauty, distortion, lack of radian, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

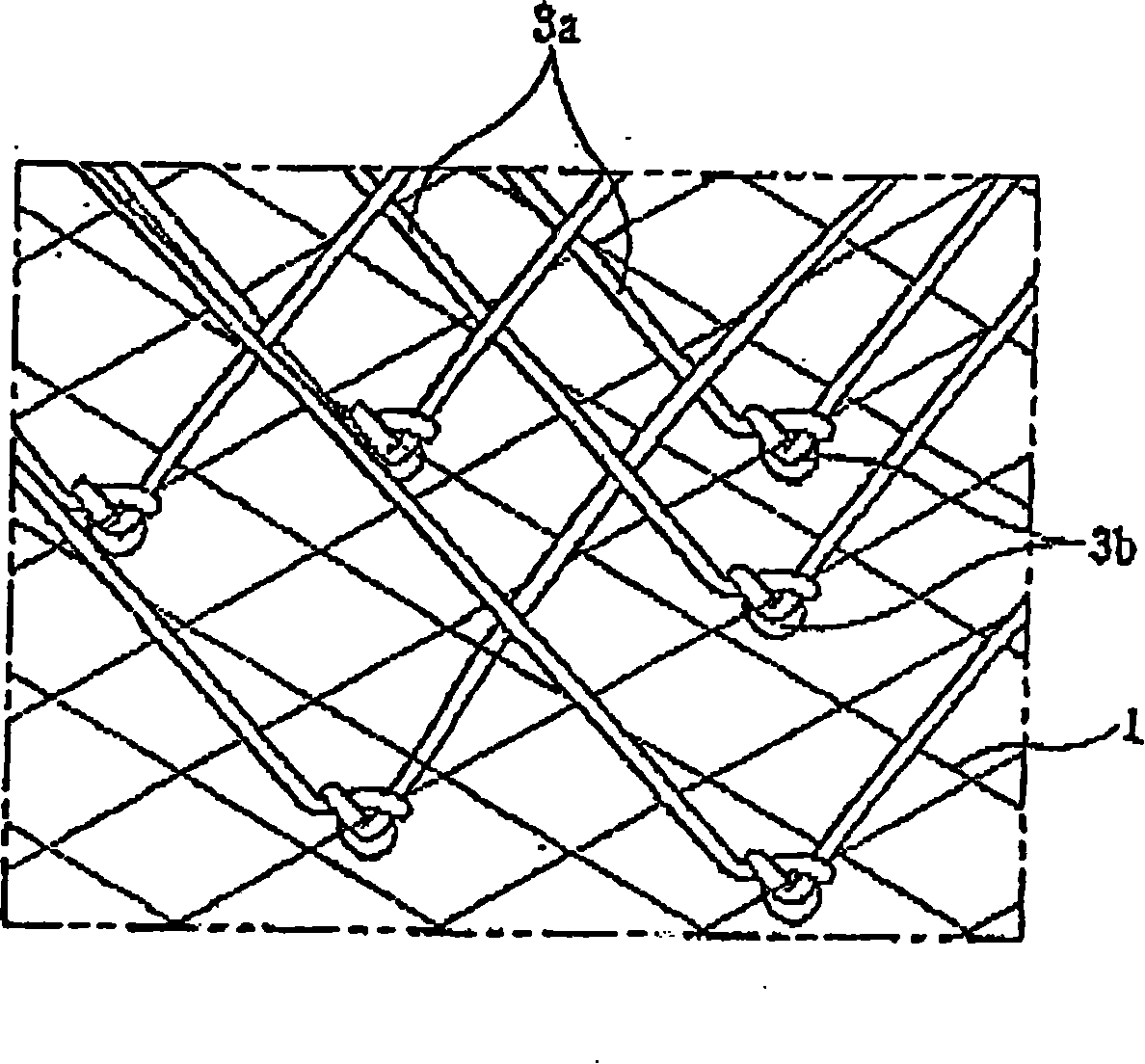

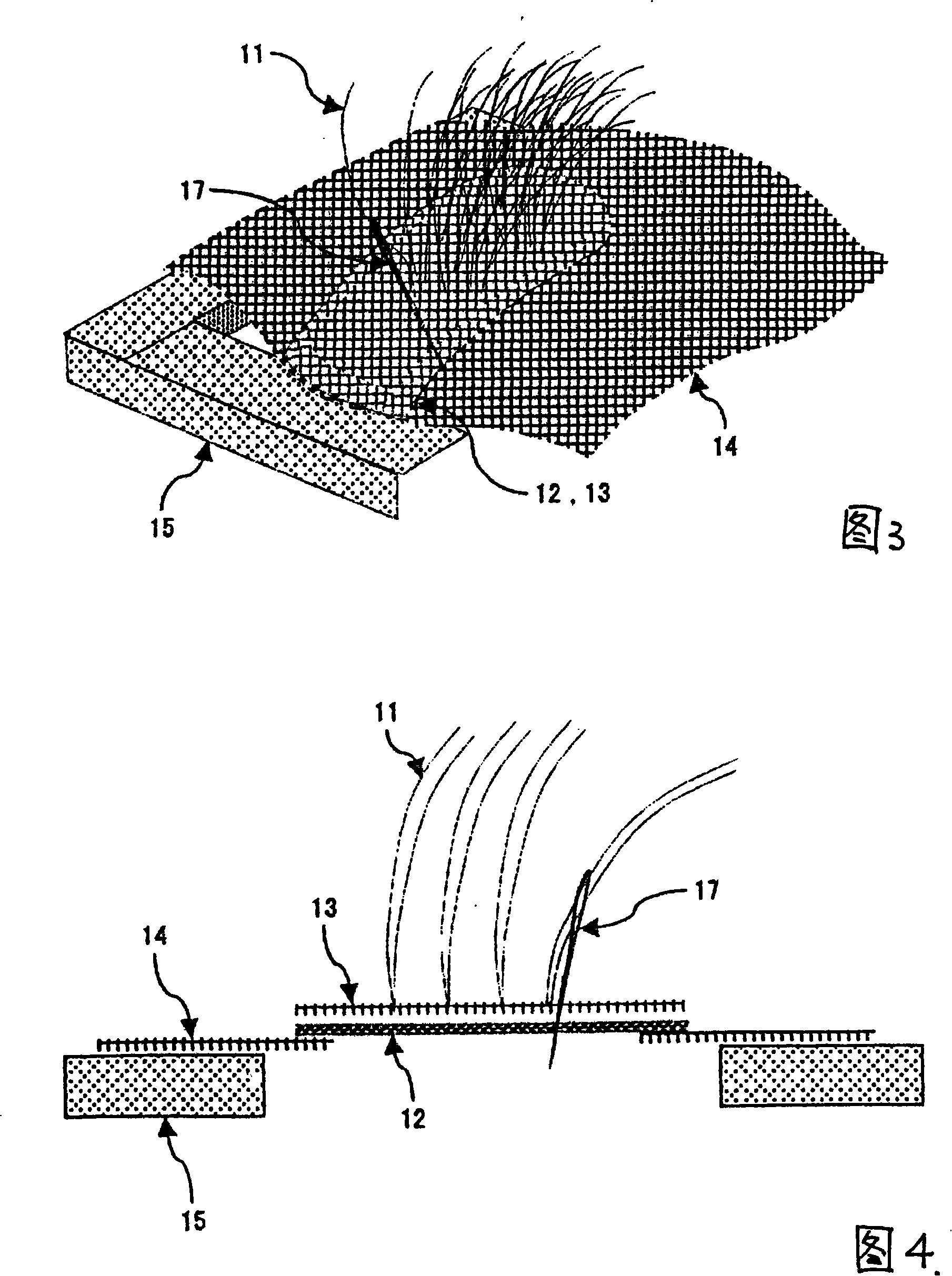

[0034] A wig with no knots on the surface of the artificial scalp according to the present invention is composed of fine mesh 13, silk 12 as the artificial scalp and hair 11. The fine mesh 13 and the silk 12 are two layers Paste together, hair transplantation and knot in the hair 11 of fine mesh 13 inner side pass through fine mesh 13 and silk-like thing 12 two layers and stretch to the outside of silk-like thing 12.

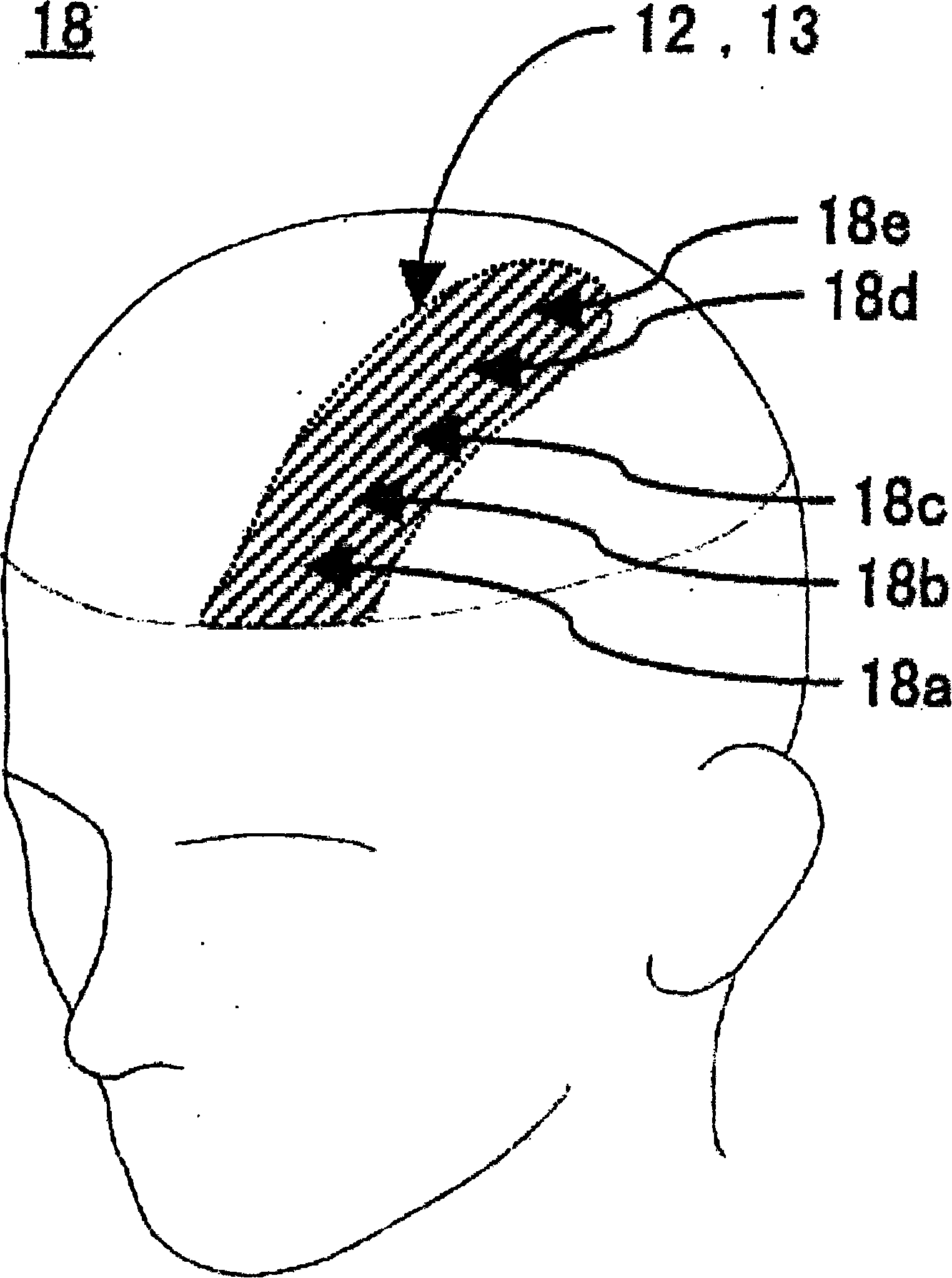

[0035] The position 12b where the hair 11 passes through the silk 12 is the intersection 12a of the normal 13b of the hair 11 passing through the fine mesh 13 position 13a and the silk 12, and may deviate from the position of the intersection 12a.

[0036] The fine mesh 13 and the silky thing 12 pasted together are sewn together along the edge with the basic net 14, and the middle part of the basic net 14 is vacant, that is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com