Apparatus for automatically regulating bi-slider position of packing machine

An automatic adjustment device and double-slider technology, applied in packaging, presses, manufacturing tools, etc., to achieve intuitive adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

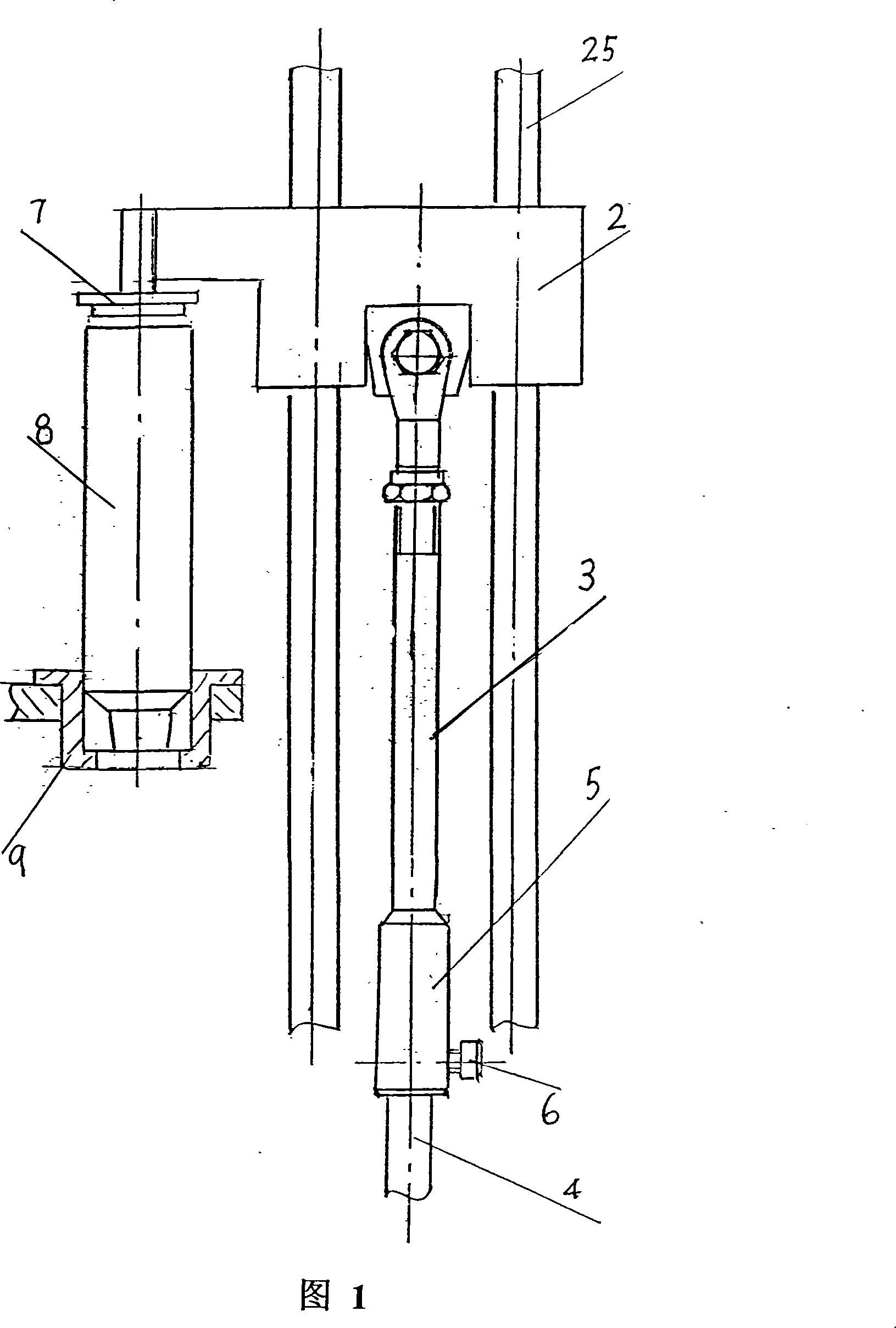

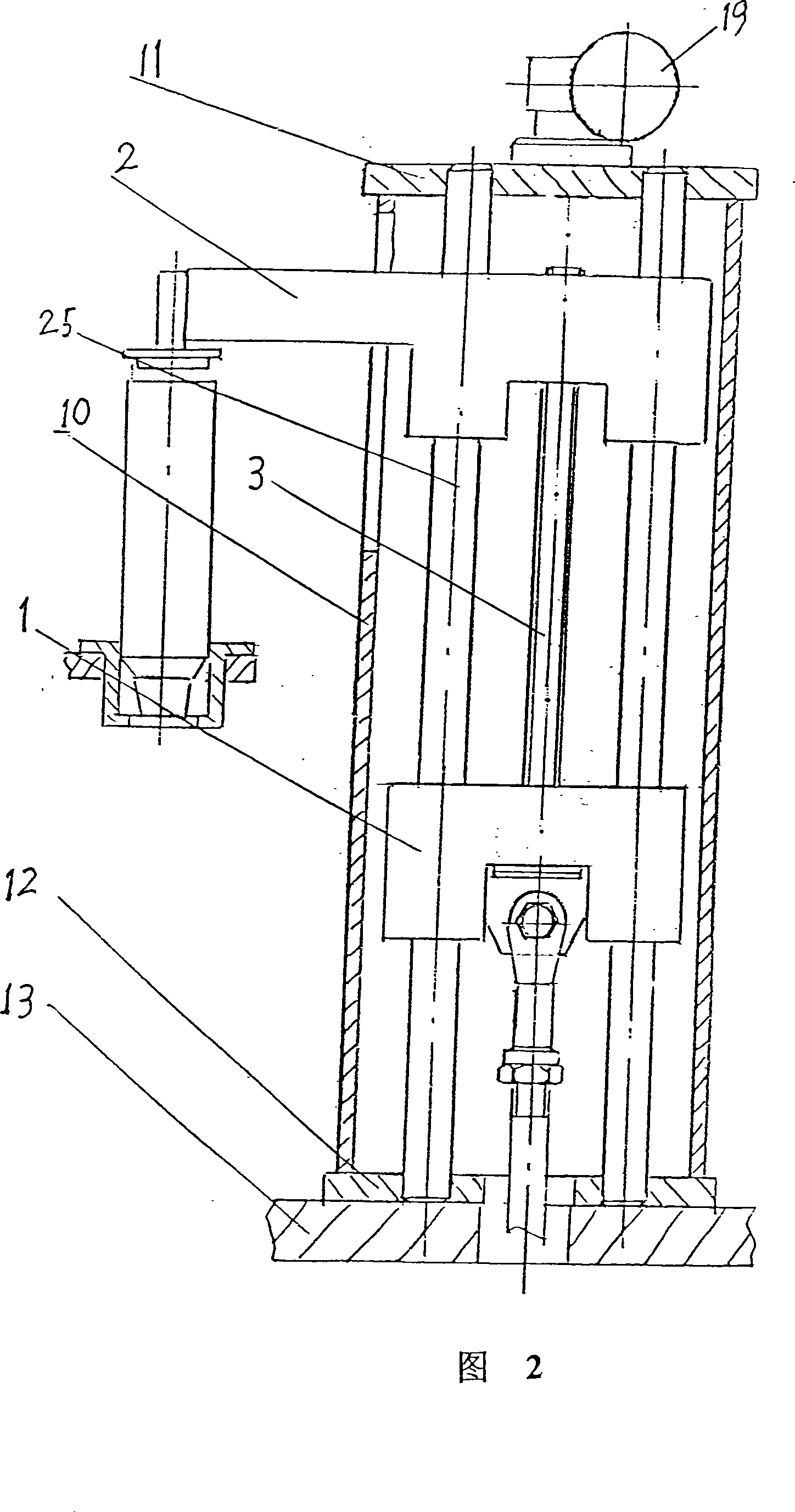

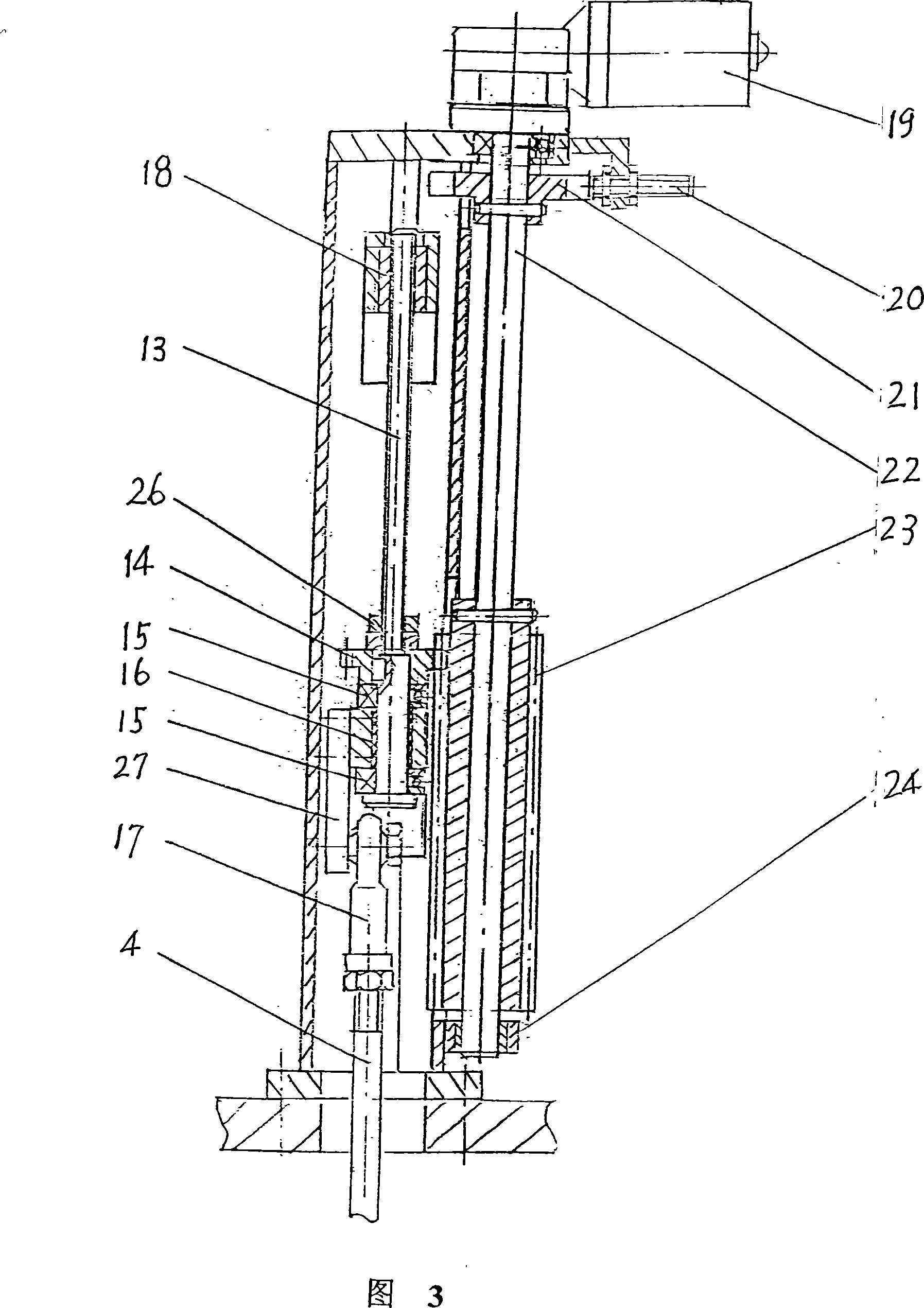

[0014] Please refer to shown in accompanying drawing 2, the present invention is at the top and the bottom of guide rod 25, is respectively provided with output slide block 2 and active slide block 1, two slide blocks pass 1,2 to connect through connecting screw rod 3, rotate connecting screw rod 3. The output slider 2 can produce relative displacement relative to the driving slider 1; a driven gear 14 is arranged at the lower part of the connecting screw 3, and the driven gear 14 is in phase with the driving gear 23 installed on a transmission shaft 22 on the casing 10. meshing, the transmission shaft 22 is connected with the motor 19 installed on the top of the frame, and the rotation of the motor 19 causes the position of the output slider 2 to change.

[0015] The length of the driving gear 23 on the transmission shaft 22 is the stroke of the upper and lower reciprocating motion of the driving slider 1 plus the maximum adjustment amount.

[0016] The connecting screw rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com