PCCP pipe-jacking relaying ring

A technology of pipe jacking and front ring, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve the inconvenient disassembly of the relay ring oil cylinder, and the relay ring cannot solve the needs of PCCP pipe jacking relay and small-angle deviation correction. Can not be reused to achieve the effect of overcoming the difficulty of jacking, preventing mud and sand from entering the pipeline, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

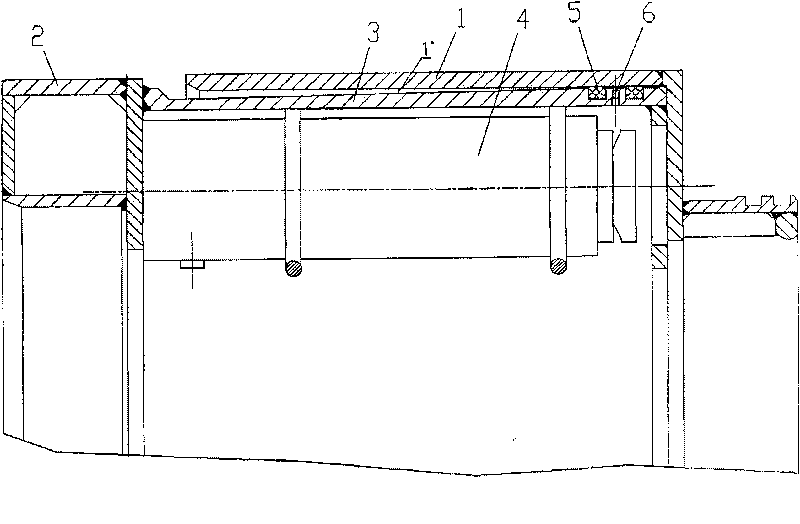

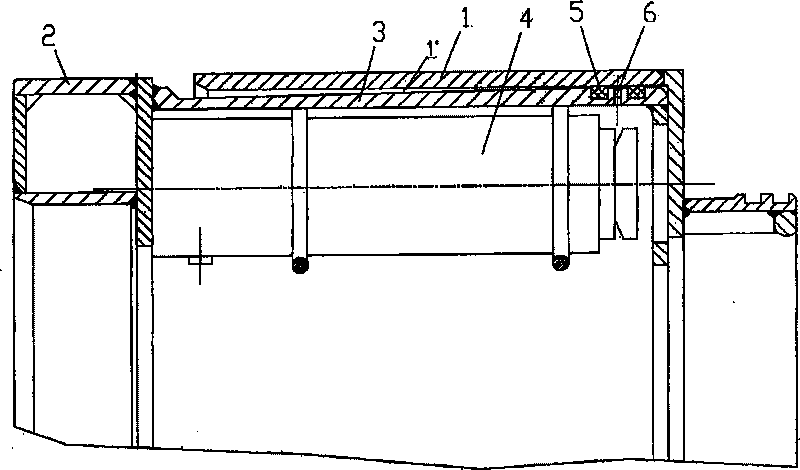

[0019] The PCCP pipe relay ring is composed of a jacking cylinder, a steel shell, a pressure ring, and a water-stop seal. The jacking cylinders are evenly distributed in the pressure ring. When the required jacking force exceeds the jacking capacity of the main jacking station, a relay ring is installed in the construction pipeline for continued jacking construction.

[0020] The φ2200PCCP pipe jacking construction used in the project, according to the calculation, arranges a relay ring every 100m. During the jacking process, the jacking of the relay ring can be controlled automatically according to the magnitude of the jacking force, or manually controlled according to the working conditions.

[0021] The φ2200PCCP relay ring is equipped with 22 500KN jacking cylinders (cylinder stroke is 400mm), the maximum jacking force is 11000KN, and the relay ring uses special sealing rubber strips, which can be adjusted by radial adjustment bolts, and can be partially or partially adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com