Drive system with fluid pump

A drive system and fluid pump technology, applied in the field of drive systems and fluid pumps, can solve the problems of increased cost and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

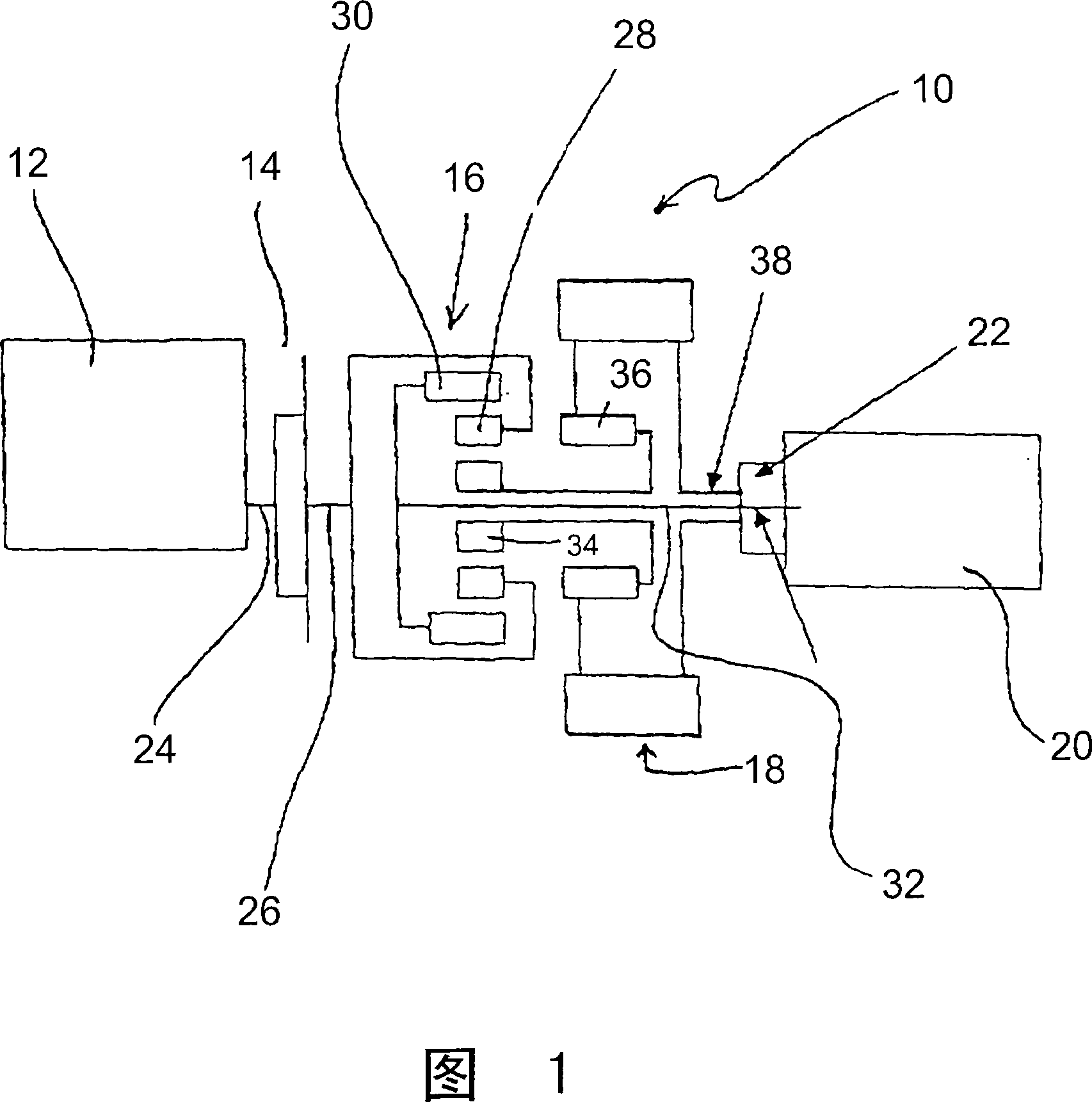

[0030] FIG. 1 shows a power flow diagram of an exemplary drive system 10 including an internal combustion engine 12 , a shock absorber 14 , a planetary gear set 16 , an electric machine 18 and an automatic transmission 20 . Both the internal combustion engine 12 and the electric machine 18 drive an automatic transmission 20 through a planetary gearset 16 . The electric motor 18 also drives a fluid pump 22 of an automatic transmission 20 .

[0031] More specifically, in the example shown, the drive system 10 is provided in the form of a parallel hybrid drive in which the internal combustion engine 12 has a mechanical drive connection to an automatic transmission 20 . Referring to FIG. 1 , the crankshaft 24 of the internal combustion engine 12 is connected to a shock absorber 14 that serves to reduce pulsation caused by the intermittent bursts of the internal combustion engine 12 . Shock absorber 14 is connected to a planet carrier 28 of planetary gear set 16 by a shaft 26 . R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com