Magnetoresistive element and magnetic memory

一种磁阻元件、元件的技术,应用在静态存储器、数字存储器信息、磁场控制的电阻器等方向,能够解决难以供给磁场等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

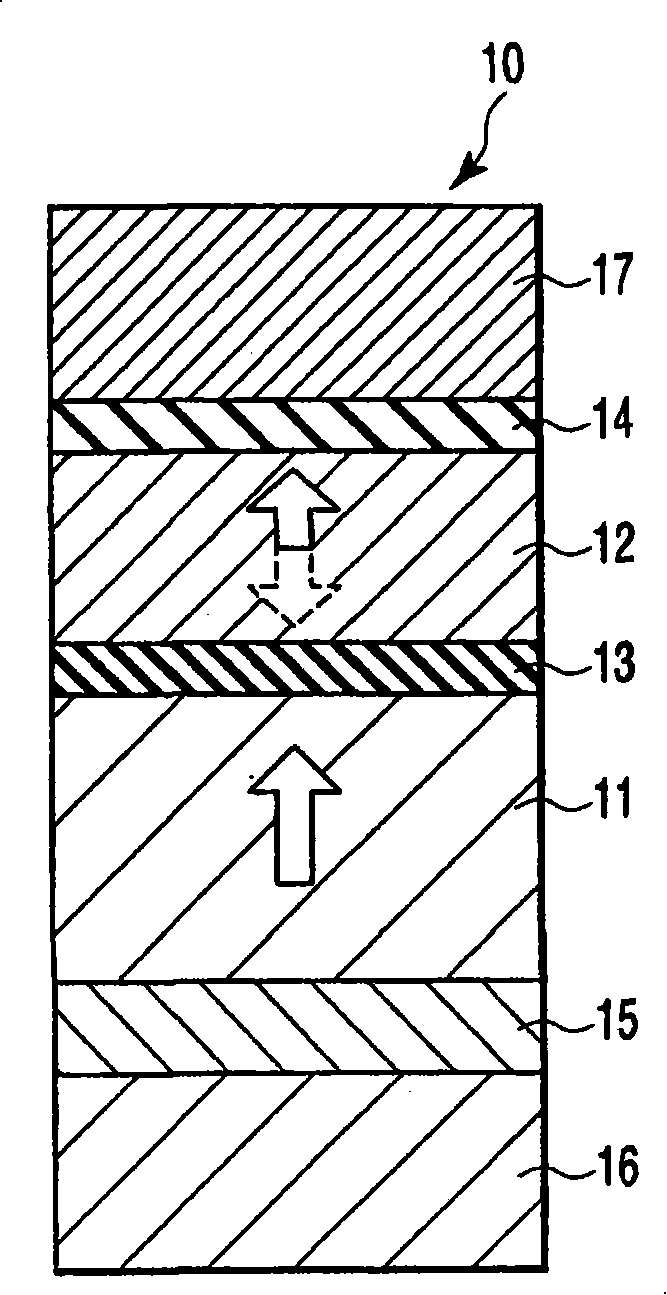

[0058] figure 1 is a sectional view showing the structure of the MTJ element 10 according to the first embodiment. figure 1 The arrows in indicate the direction of magnetization. In this embodiment, an MTJ element 10 having a single pinned layer structure (ie, a structure in which a free layer and a pinned layer are arranged on both sides of a nonmagnetic layer) will be described.

[0059] The MTJ element 10 has a crystal orientation lower layer 15, a pinned layer (also called a magnetization pinned layer or pinned layer) 11, a tunnel barrier layer (nonmagnetic layer) 13, a recording layer (also called a magnetization free layer or A layered structure formed by a free layer) 12 and a capping layer 14. The layered structure may have a reverse stacking order. Lower electrode 16 is provided on the lower surface of crystal orientation lower layer 15 . The upper electrode 17 is provided on the upper surface of the cap layer 14 .

[0060] The pinned layer 11 has a fixed magneti...

no. 2 example

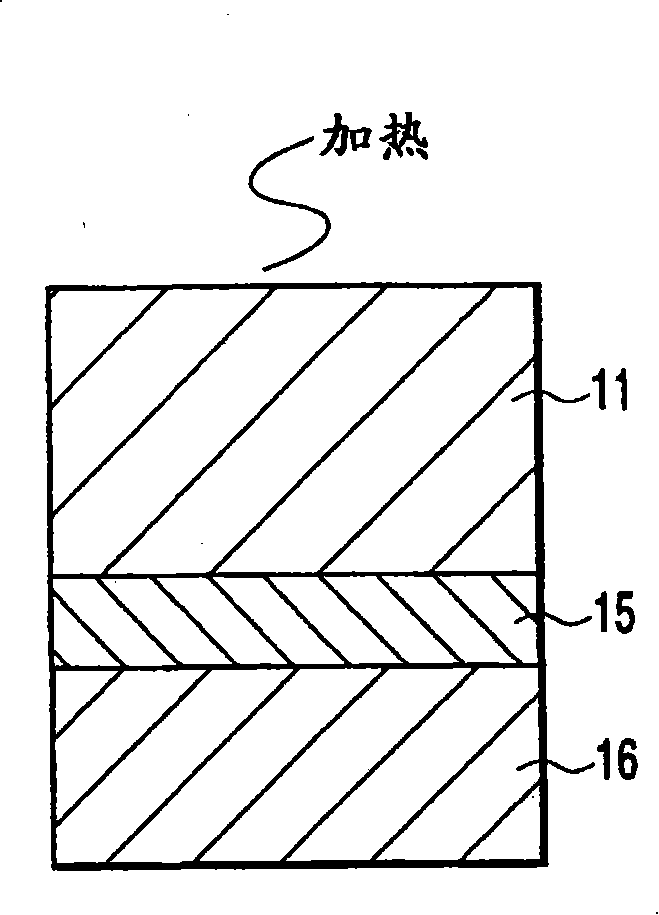

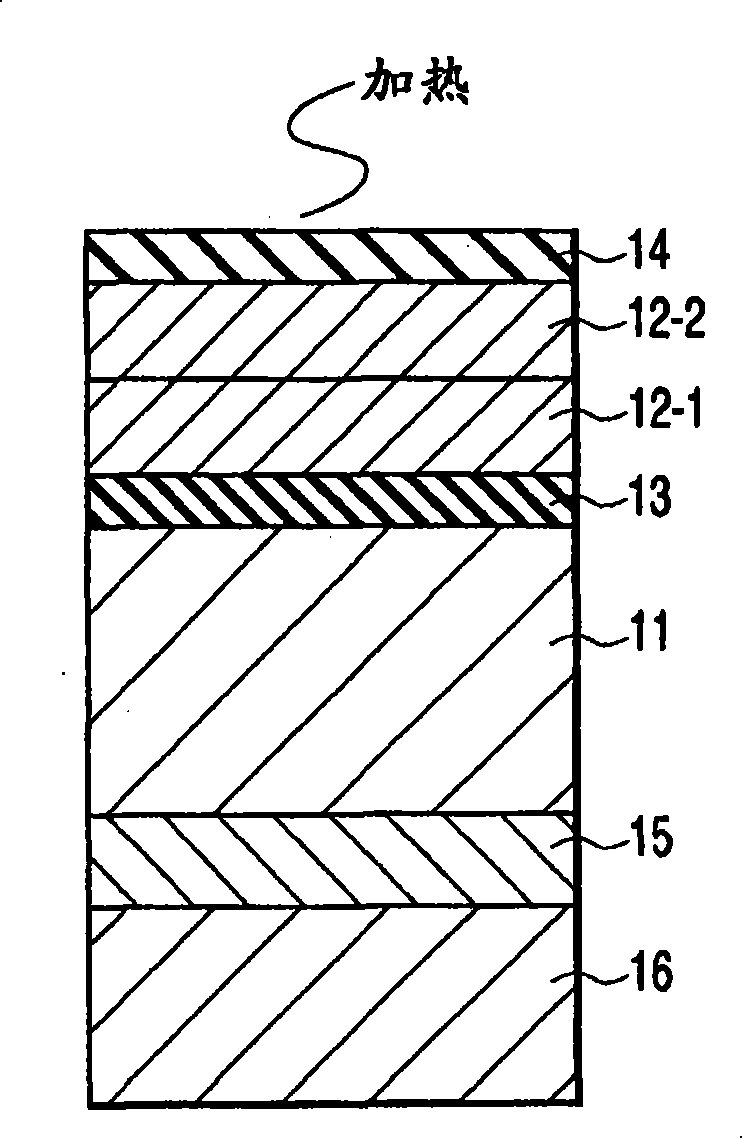

[0116] In the second embodiment, a magnetic layer for controlling the crystallinity of the tunnel barrier layer 13 is inserted between the tunnel barrier layer 13 and the pinned layer 11 , thereby increasing the crystallinity of the tunnel barrier layer 13 and the recording layer 12 .

[0117] Figure 4 is a sectional view showing the structure of the MTJ element 10 according to the second embodiment. In this embodiment, an MTJ element 10 having a single pinned layer structure will be explained.

[0118] The MTJ element 10 has a layered structure formed by sequentially stacking a crystal orientation lower layer 15 , a pinned layer 11A, an interface pinned layer 11B, a tunnel barrier layer 13 , a recording layer 12 , and a cap layer 14 . Layered structures may have a reverse stacking order. Lower electrode 16 is provided on the lower surface of crystal orientation lower layer 15 . The upper electrode 17 is provided on the upper surface of the cap layer 14 .

[0119] The fix...

no. 3 example

[0122] In the third embodiment, a magnetic layer for enhancing the magnetoresistance effect is inserted between the recording layer 12 and the tunnel barrier layer 13, thereby improving the characteristics of the MTJ element 10.

[0123] Figure 5 is a sectional view showing the structure of the MTJ element 10 according to the third embodiment. In this embodiment, an MTJ element 10 having a single pinned layer structure will be explained.

[0124] The MTJ element 10 has a layered structure formed by sequentially stacking a crystal orientation lower layer 15 , a fixed layer 11 , a tunnel barrier layer 13 , an interface recording layer 12B, a recording layer 12A, and a capping layer 14 . Layered structures may have a reverse stacking order. Lower electrode 16 is provided on the lower surface of crystal orientation lower layer 15 . The upper electrode 17 is provided on the upper surface of the cap layer 14 .

[0125] The recording layer 12 of this embodiment is formed by lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com