Secondary battery

A technology for secondary batteries and battery boxes, which is applied to battery pack components, battery covers/end covers, battery boxes/coatings, etc., and can solve problems such as reduced impact resistance, reduced strength of insulating rings, and damage to exhaust paths. Achieve the effects of preventing breakage, ensuring the total area, and high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

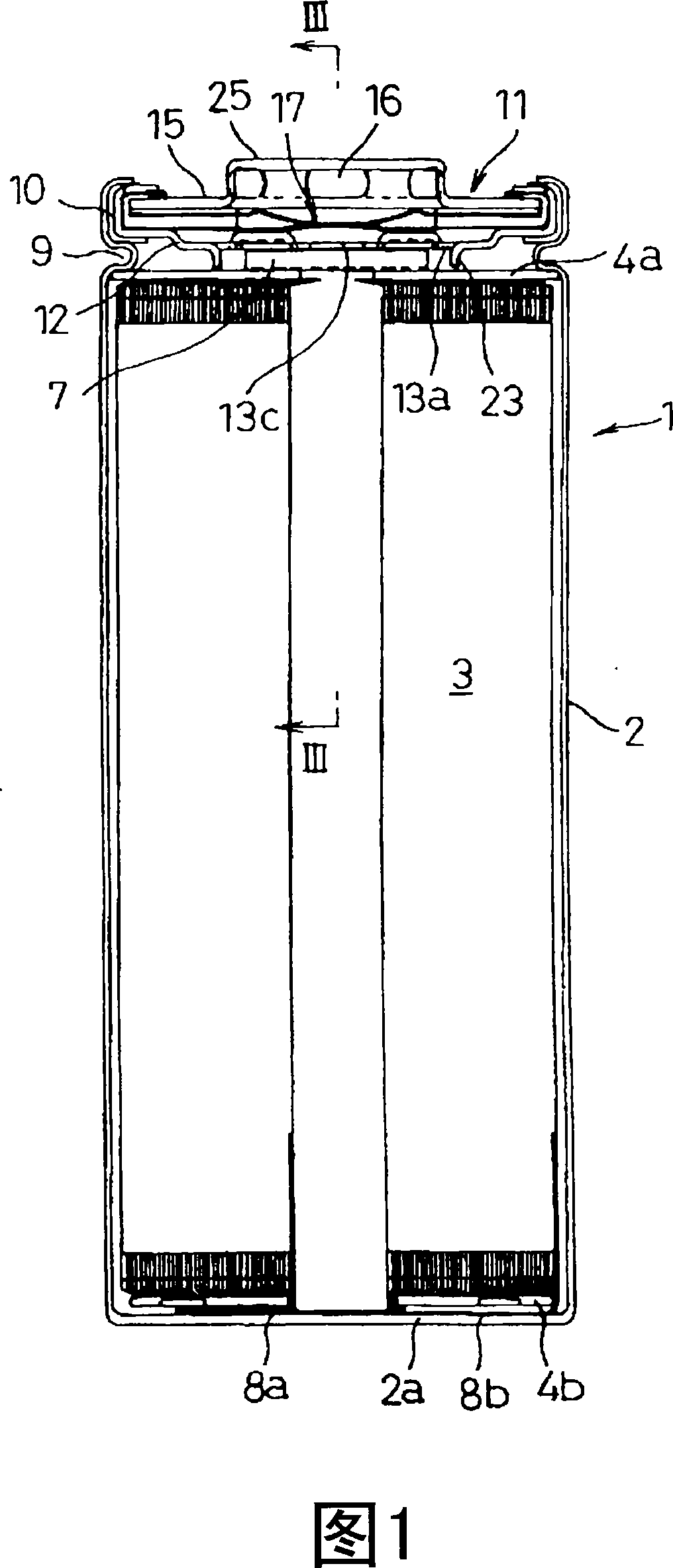

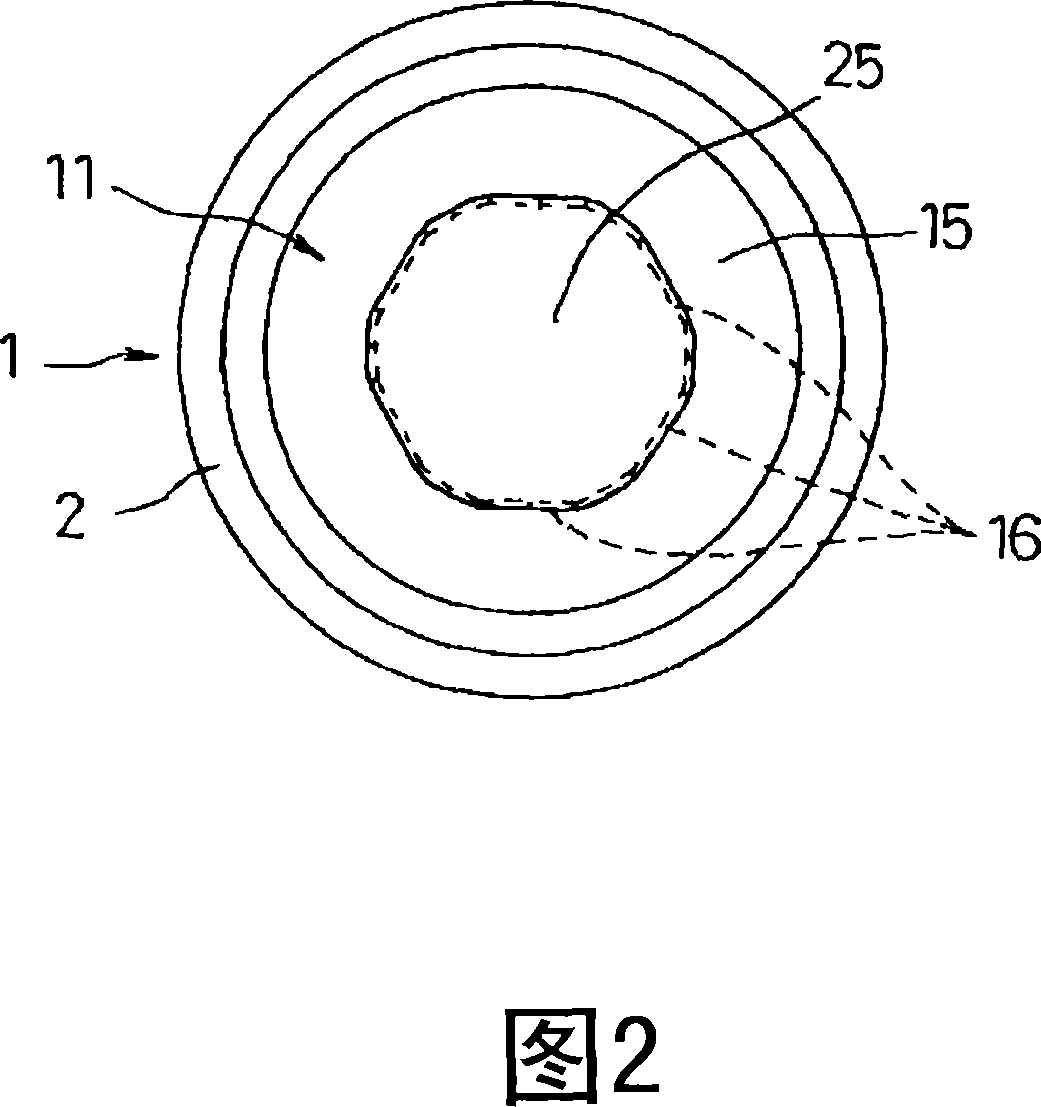

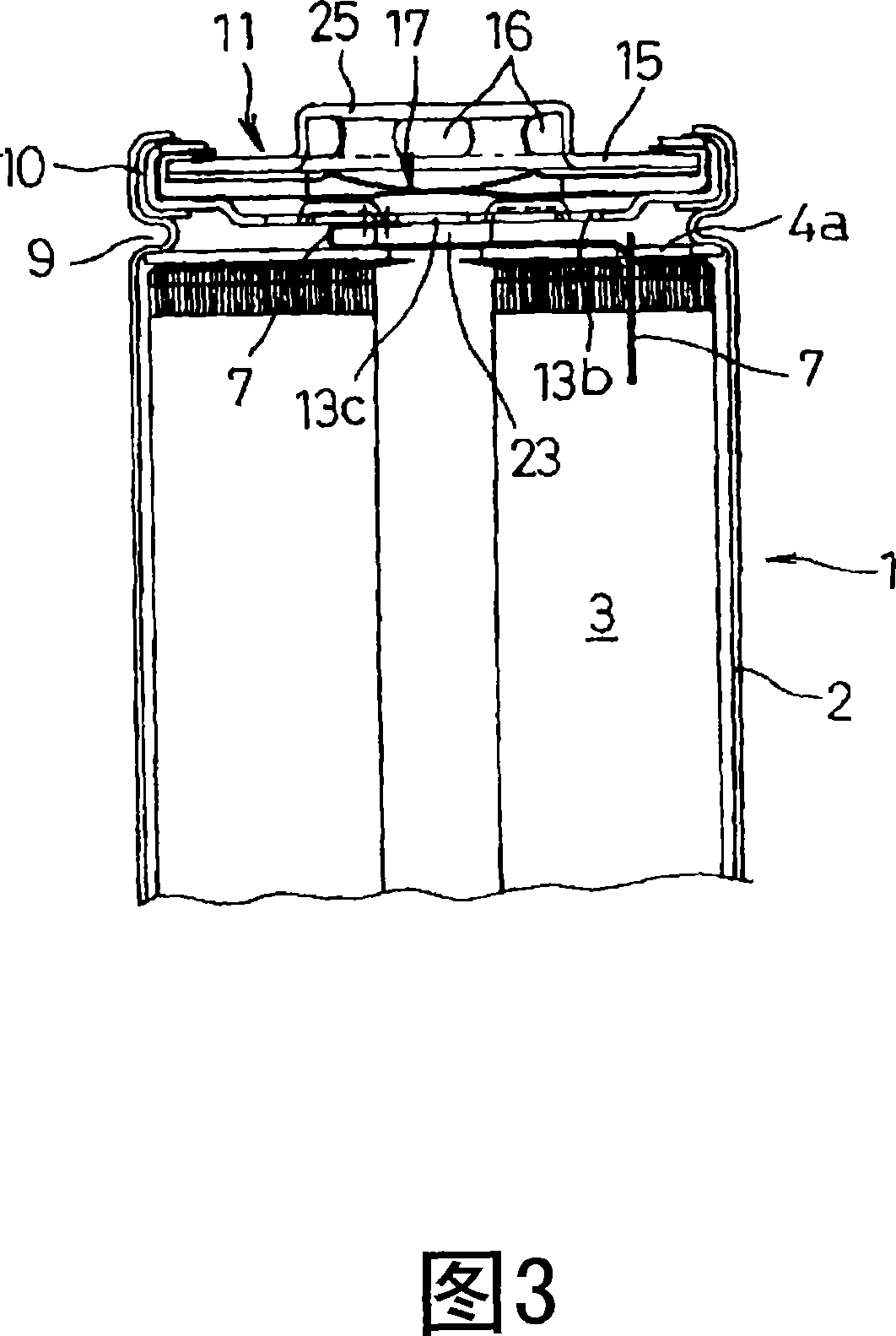

[0034] Hereinafter, an embodiment of the secondary battery of the present invention will be described with reference to FIGS. 1 to 8B.

[0035] In Figures 1 to 3, 1 is a cylindrical secondary battery composed of a lithium ion battery. A bottomed cylindrical battery box 2 contains an electrode group 3 as a power generation element together with electrolyte. . The electrode plate group 3 is formed by winding a strip-shaped positive electrode plate, a separator, a negative electrode plate, and a separator on the outer circumference of the core member in a state where they are sequentially stacked, and the core member is pulled out after the winding is completed. It is a structure in which a positive electrode plate and a negative electrode plate are laminated with a separator sandwiched between them. The separator protrudes up and down by an appropriate size from the positive electrode plate and the negative electrode plate. The upper and lower protrusions of the separator are bent r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com