Solid oxide fuel cell

A solid oxide and fuel cell technology, used in solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve the problems of increased heat loss due to large-scale shapes, impossible recirculation of fuel gas, and complex sealing structures. The effect of reduced heat loss, simple structure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

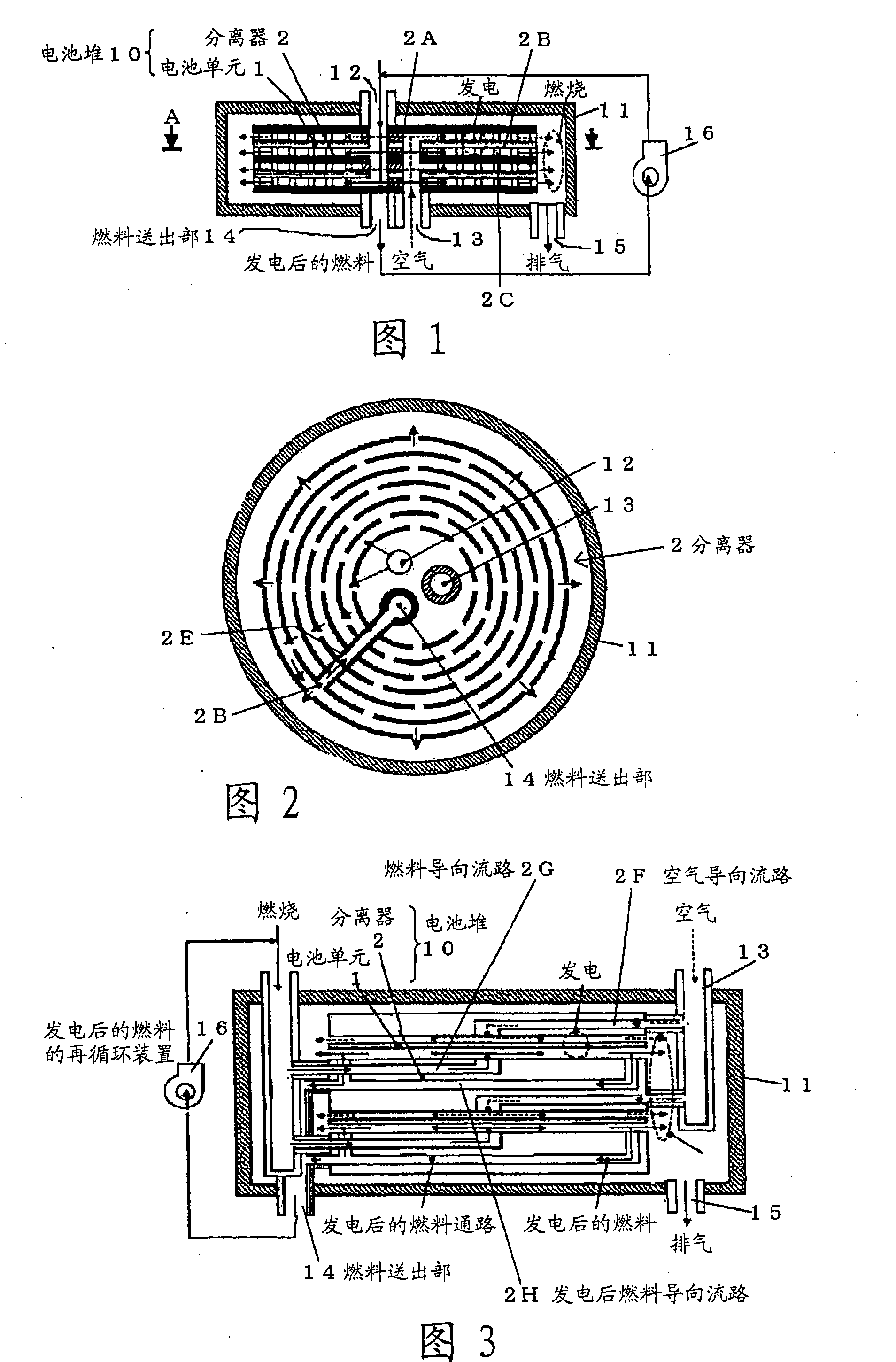

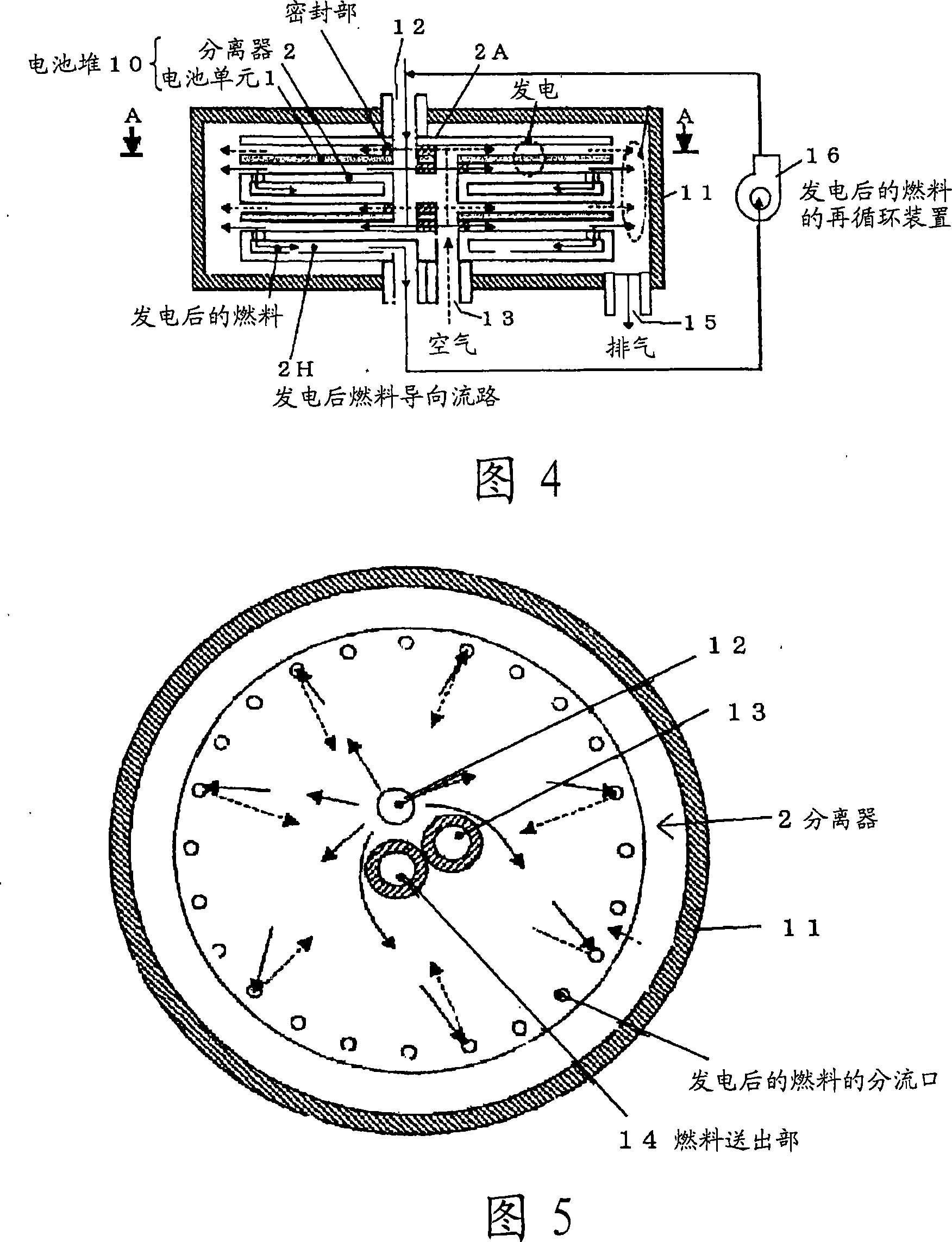

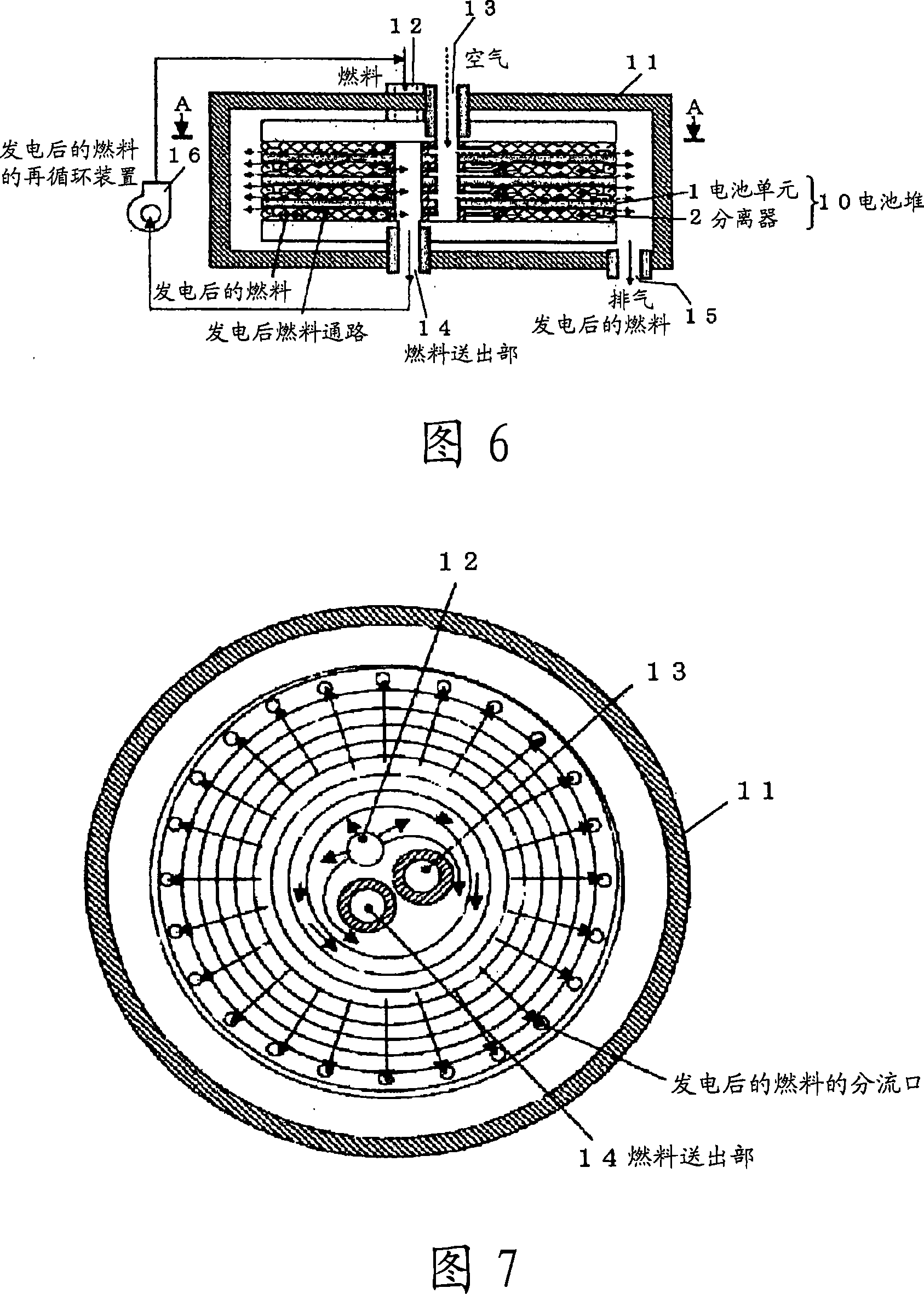

[0057] Next, embodiments of the solid oxide fuel cell of the present invention will be described in detail with reference to the drawings.

[0058]Fig. 1 is a longitudinal sectional view showing an embodiment of a solid oxide fuel cell according to the present invention, and Fig. 2 is a sectional view taken along line A-A in Fig. 1 .

[0059] This solid oxide fuel cell is constructed by accommodating a cell stack 10 in which disc-shaped battery cells 1 and disc-shaped separators 2 are stacked alternately in a case 11 .

[0060] In addition, the solid oxide fuel cell is provided with: a fuel supply part 12 penetrating through the central part of the upper wall of the case 11 for supplying fuel to the central part of the cell stack 10; an air supply part 13 penetrating through the case The central part of the lower wall of the body 11 is used to supply air to the central part of the battery stack 10; the fuel delivery part 14 penetrates through the central part of the lower wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com