Material separating disc for impact sand production machine

A technology of material distribution tray and sand making machine, which is applied in the direction of grain processing, etc., which can solve the problems of increased replacement cost and shortened service life, and achieve the effect of reducing loss, reducing impact and wear, and facilitating crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

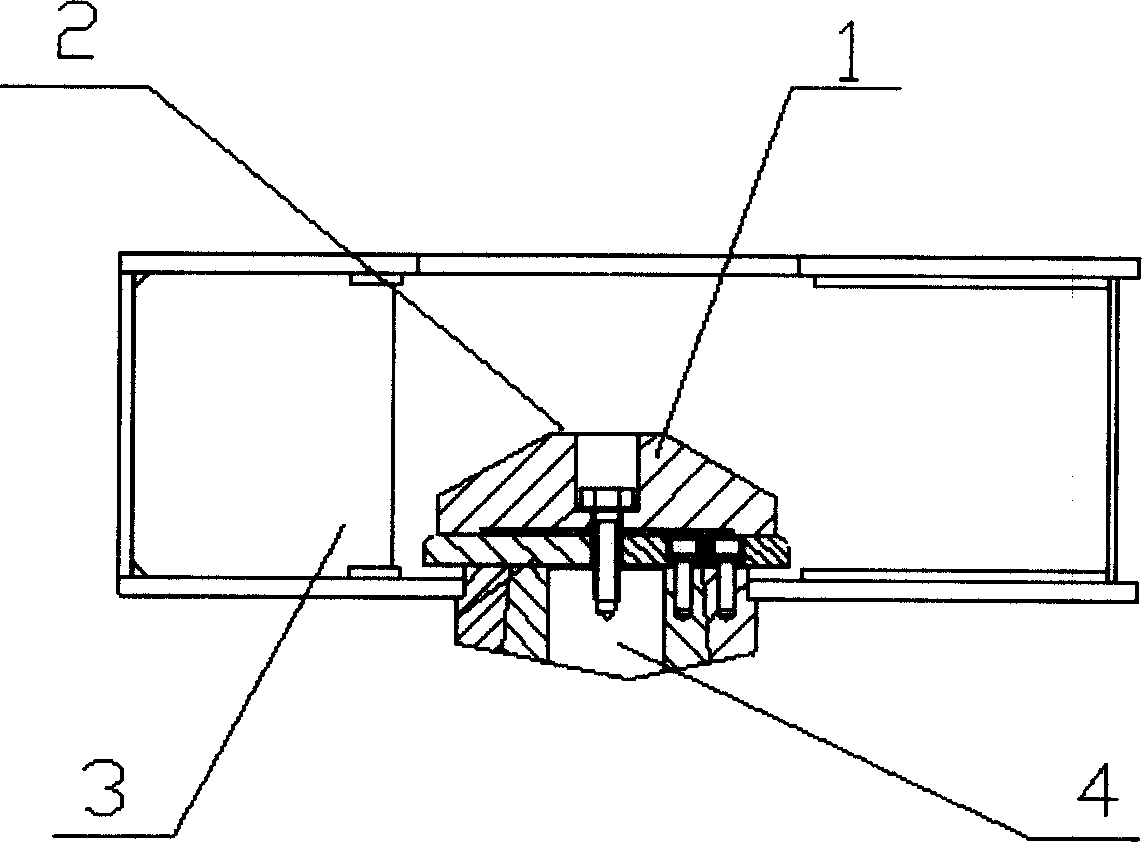

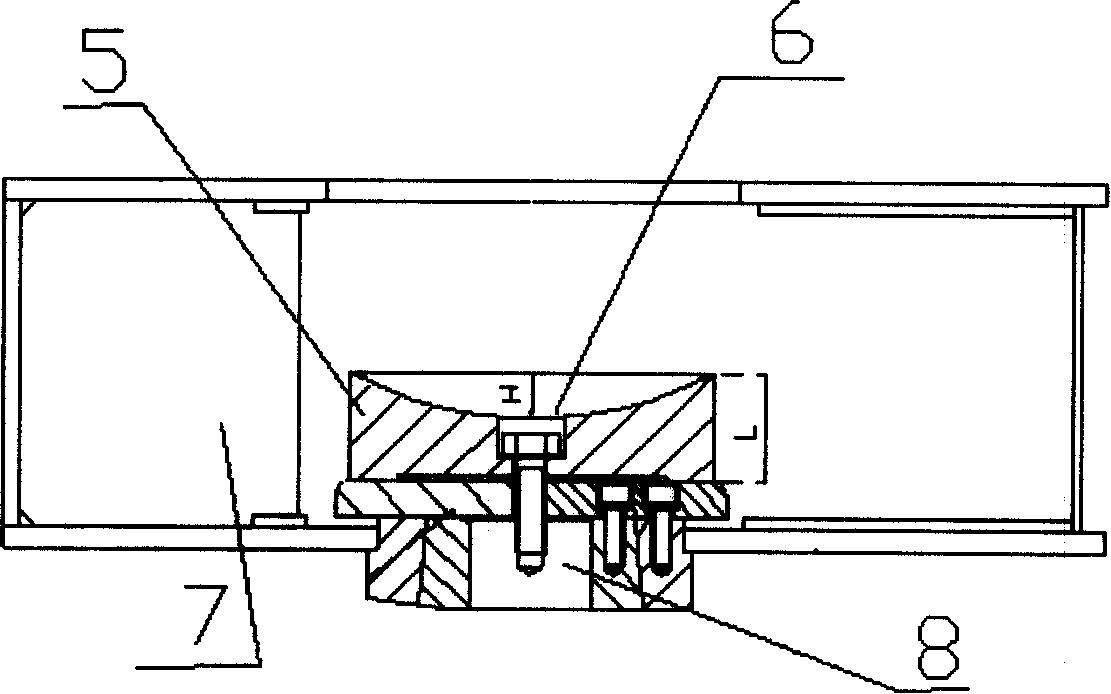

[0009] figure 2 It is a structural schematic diagram of the concave material distribution tray designed by the present invention. The upper part of the distribution tray 5 adopts a concave surface 6, the distribution tray 5 is fixed on the rotor 7, and the rotor 7 is fixed on the shaft system 8. The concave surface 6 can adopt a spherical concave surface or other arc concave surfaces, and can also adopt other regular or irregular concave surfaces as required.

[0010] The concave height of the concave surface 6 ( figure 2 H) accounts for the thickness of the entire distribution tray ( figure 2 1 / 3-2 / 5 of L), so that when the material falls to the distribution tray, some material will be accumulated on the concave surface 6, which acts as a material pad. When the material continues to fall, it will fall on the accumulated On the material, the distribution plate is not easy to wear, because the accumulated material plays a role in protecting the distribution plate. Using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com