Synchronous bag cutting device

A bag-cutting and knife-cutting technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of low bag-making efficiency, non-zipper bags, unstable strength and time, etc., to reduce losses, reduce Impact force and abrasion, the effect of improving bag cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The lower surface further describes the present invention in detail through specific embodiments. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention.

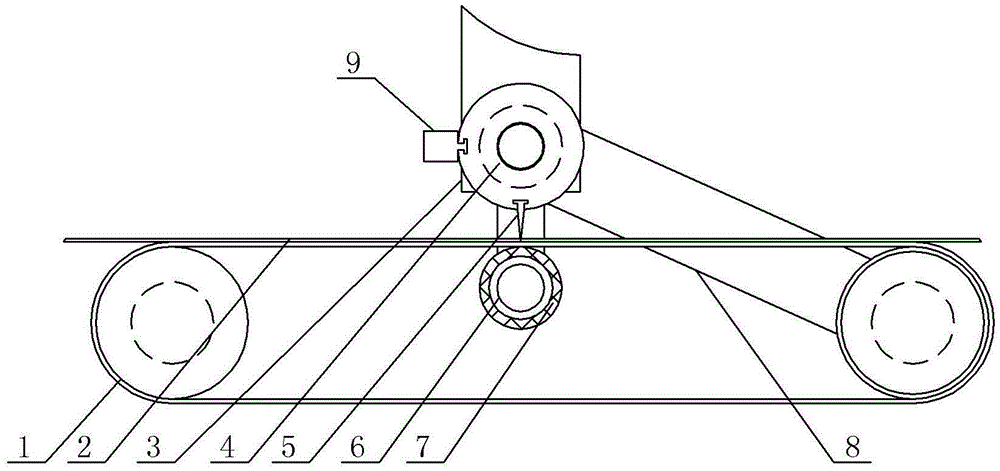

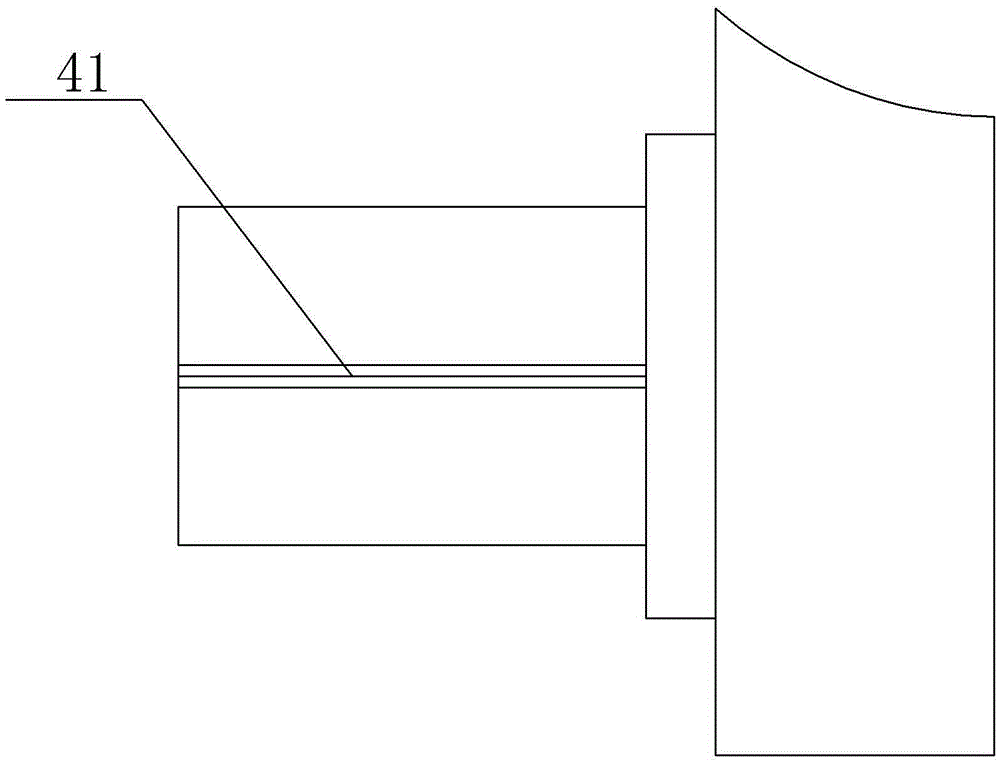

[0014] The reference signs in the accompanying drawings include: belt transmission mechanism 1, forming zipper bag 2, frame 3, rotary cutter body 4, cutter 5, supporting roller 6, rubber sleeve 7, first belt 8, counterweight 9 , Groove 41.

[0015] A synchronous bag cutting device, such as figure 1 As shown, the molded zipper bag is placed on the belt transmission mechanism 1 and is continuously transported forward. The top of the belt of the belt conveying mechanism 1 is provided with a synchronous cutter mechanism, the synchronous cutter mechanism includes a rotary cutter body 4, a cutter 5 and a first belt 8, the rotary cutter body 4 is connected with the frame 3 in rotation, and the rotary cutter b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com