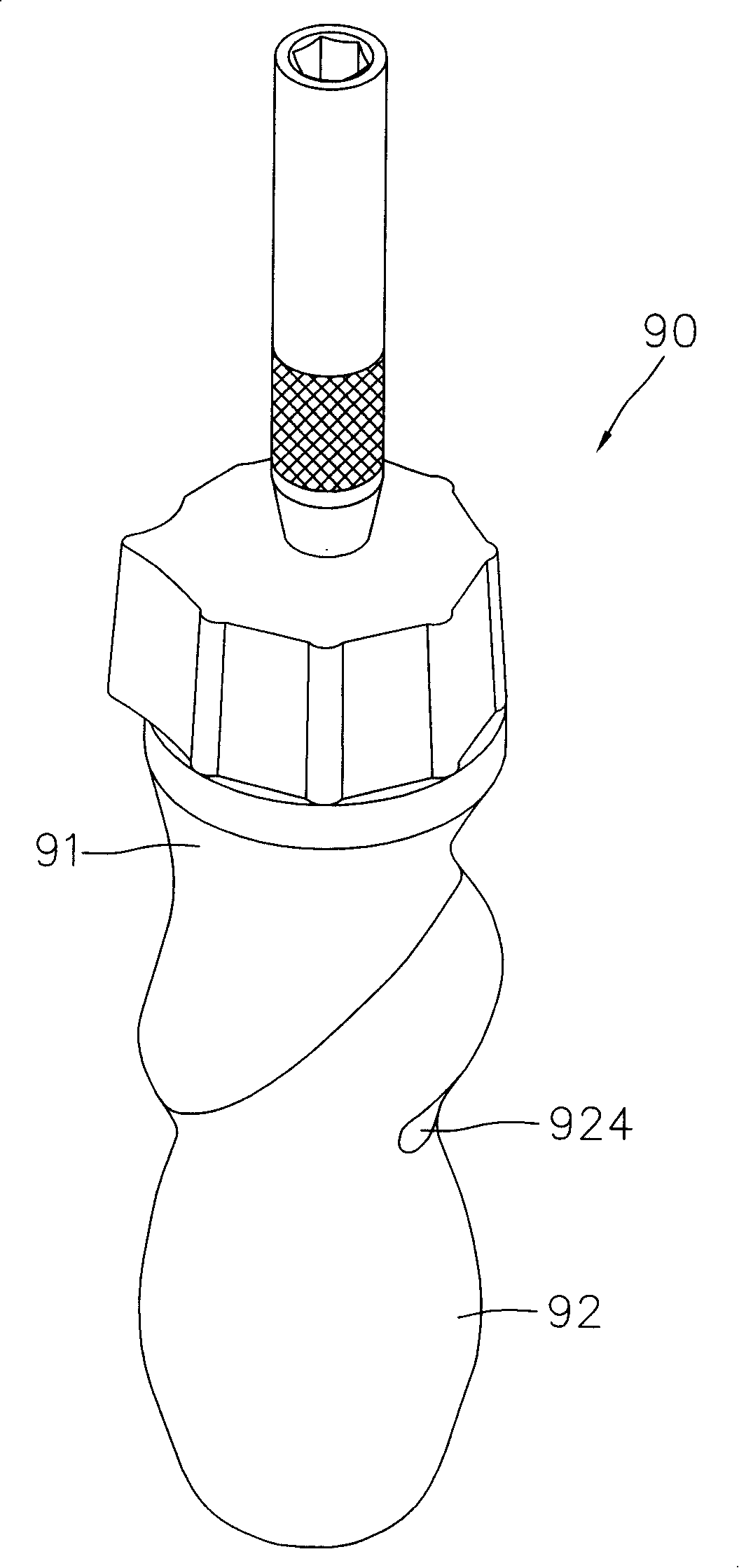

Ratchet screw handle torsion structure

A grip and ratchet technology, which is applied to wrench, wrench, screwdriver, etc., can solve the problems of affecting the pivoting effect or positioning effect, easy to accumulate dust, and unsightly appearance design, so as to achieve good positioning effect and reduce the number of handles. The effect of volume and extended moment arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

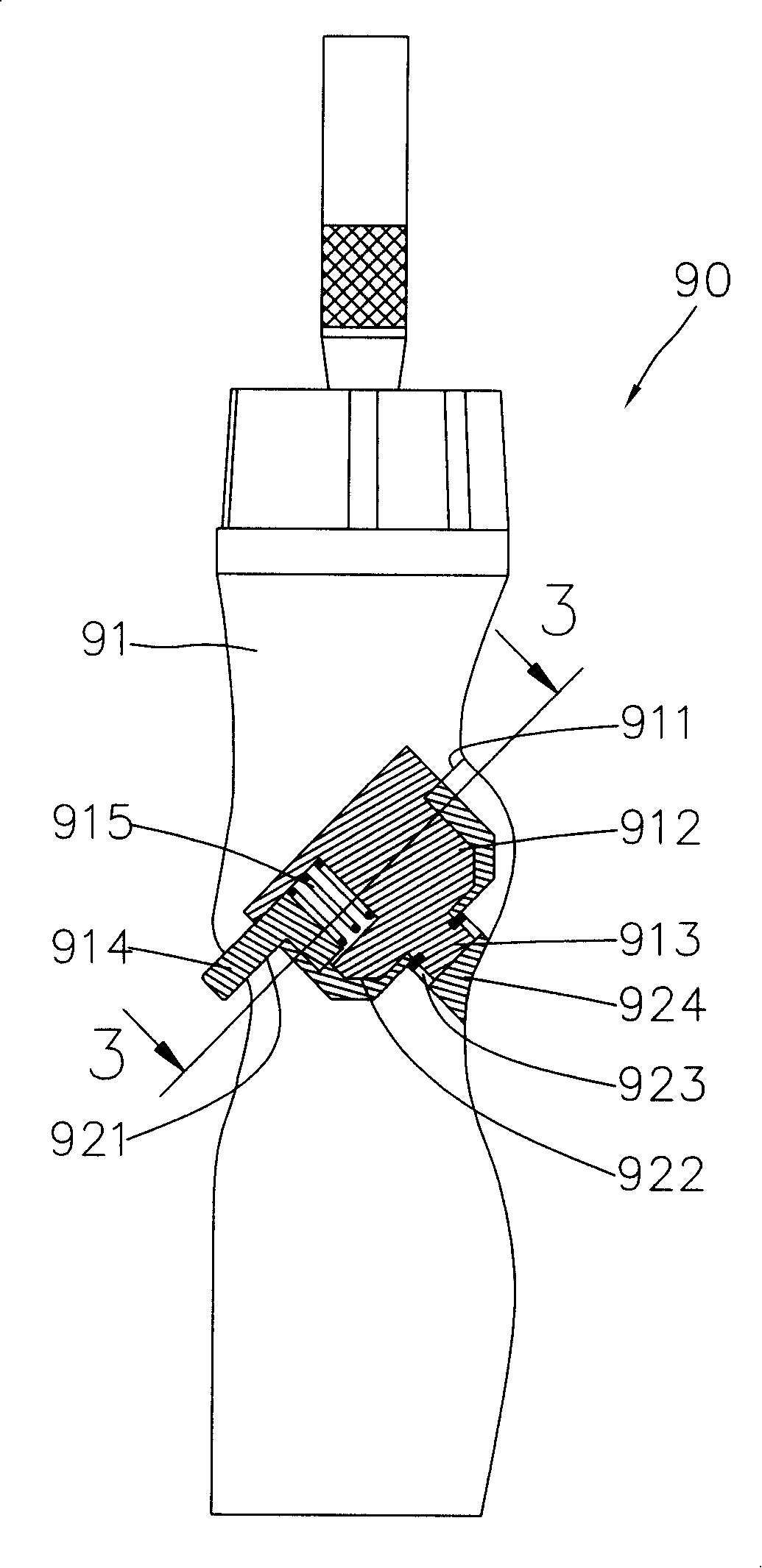

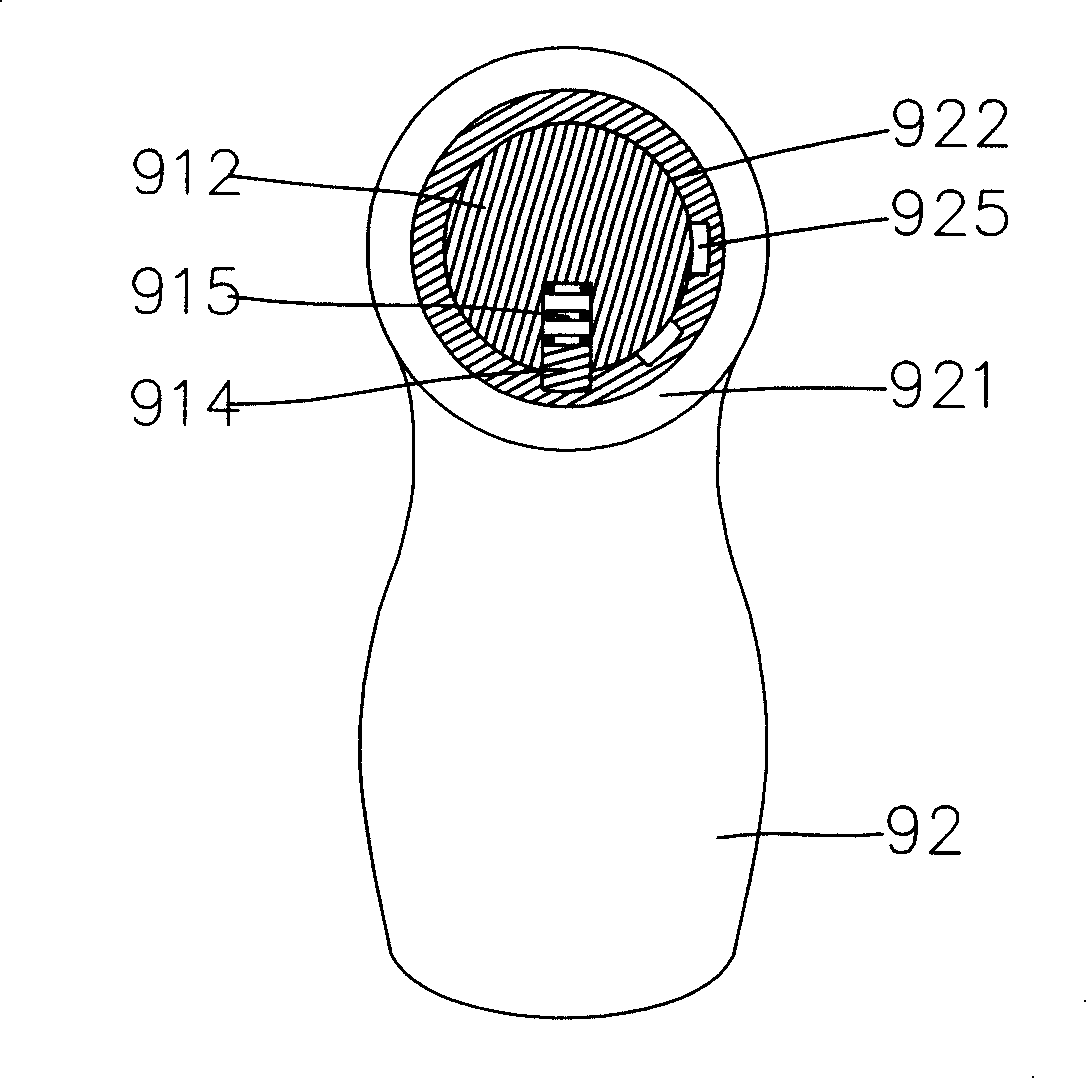

[0029] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

[0030] refer to Figure 5 and Image 6 , the handle 1 of the present invention includes a first handle 10, a second handle 20 and a positioning device 30; one end of the second handle 20 is pivotally arranged on one end of the first handle 10, and can be positioned by the positioning The device 30 is torsionally positioned between a first position and a second position. in:

[0031] Please cooperate with the reference Figure 7 , the first handle 10 has a first end and a second end, and the first end is provided with a chamber 11 for screwing a cover 15 , thereby accommodating several screwdriver bits 16 . The second end of the first handle 10 is formed with an inclined end surface 12 , and the end surface 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com