Method for optimizing pneumatic connecting line or yarn and corresponding equipment

A technology for connecting equipment and connecting lines, which is applied to spinning machines, jointing devices, transportation and packaging, etc., and can solve the problems of heavy adjustment or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

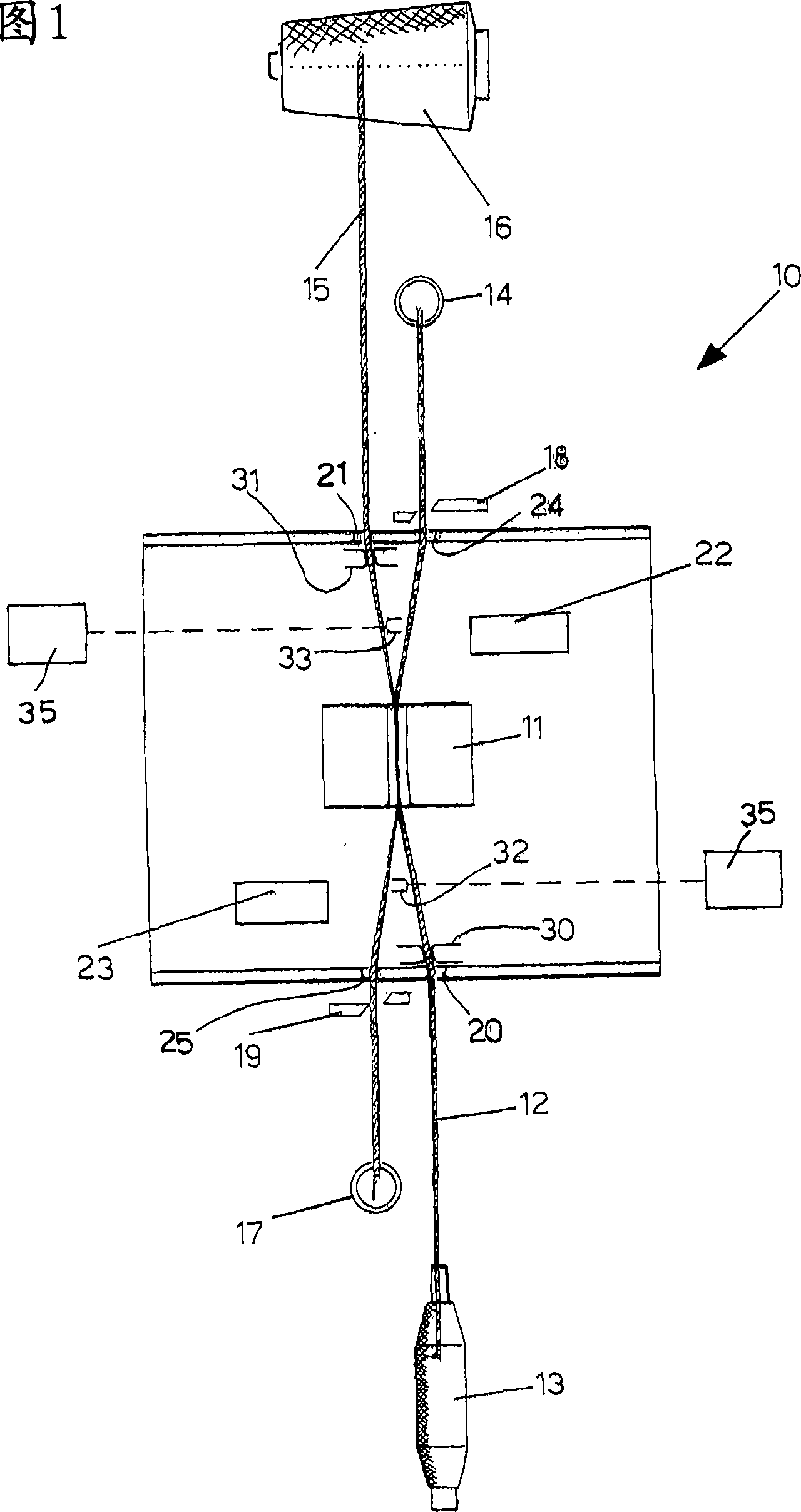

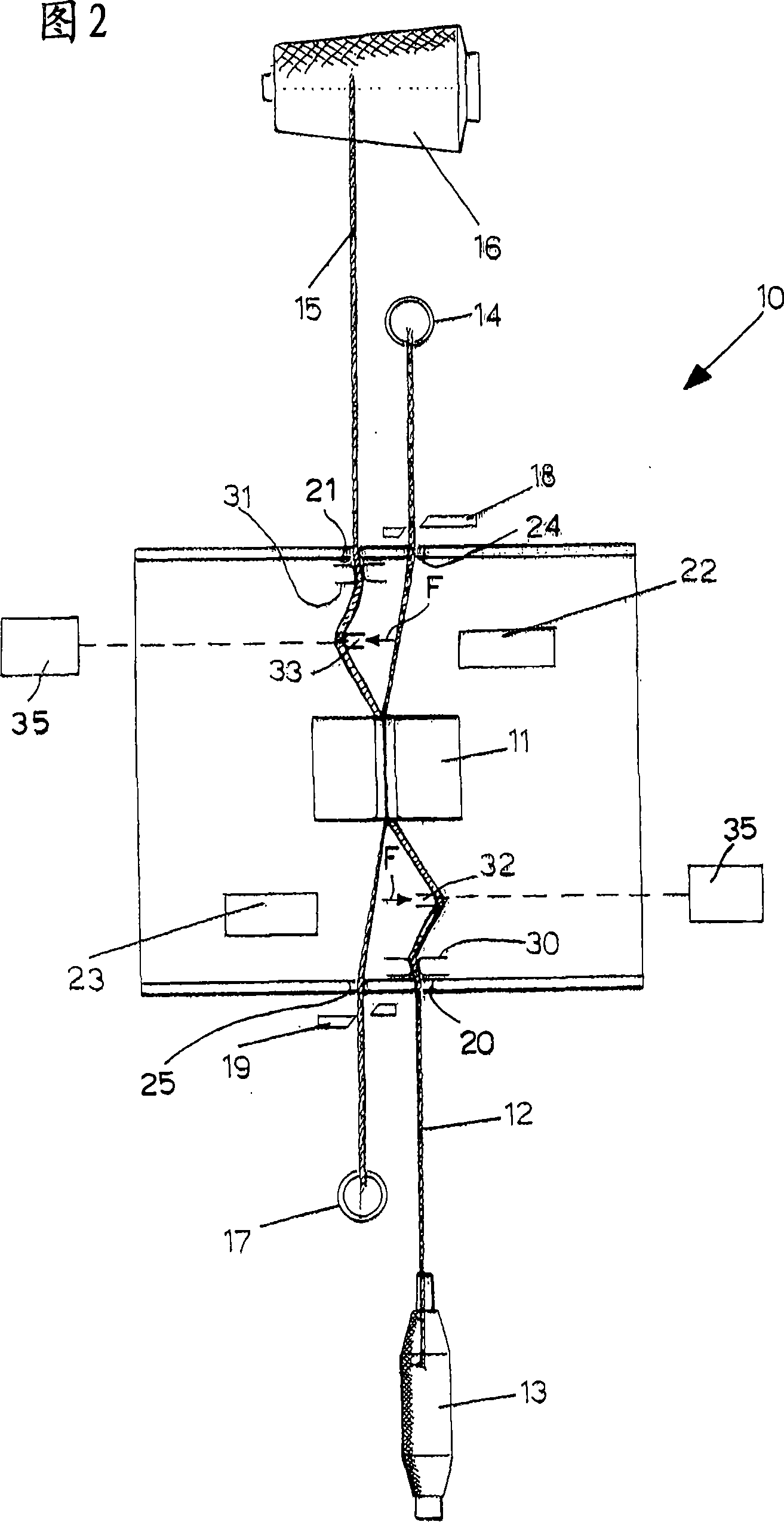

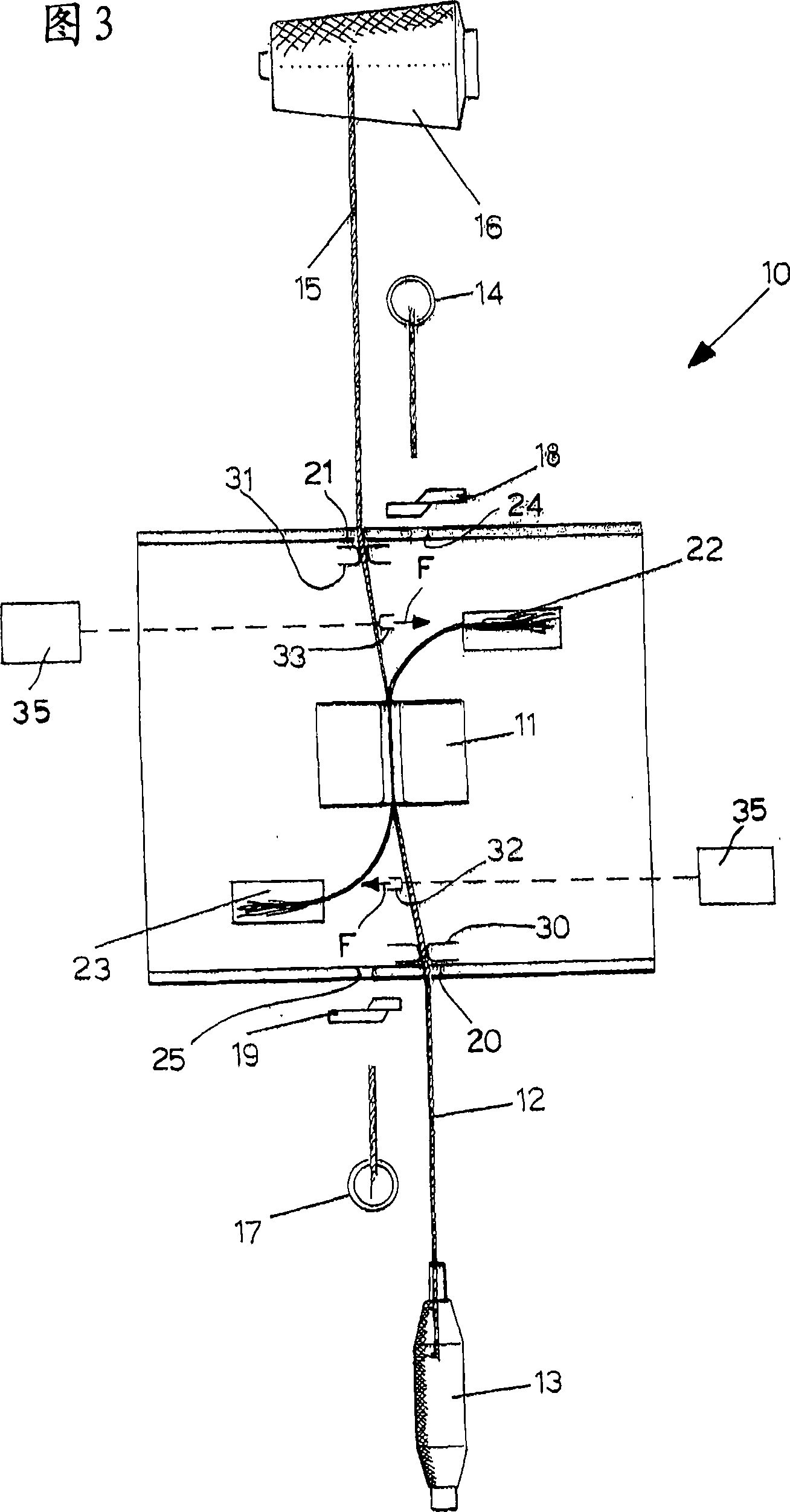

[0019] With reference to these figures, as an example, a device 10 for pneumatically joining threads or yarns is schematically shown for carrying out the method object of the invention for optimizing pneumatically joining threads or yarns.

[0020] In particular, the device 10 has a coupling chamber 11 inside which multiple streams of compressed air can be supplied through suitable nozzles not shown. Furthermore, the coupling chamber 11 is provided with a cover, which is also not shown. As shown in FIG. 1 , the first wire 12 from the bobbin 13 is introduced into the device 10 through the guide sleeve 20 , passed through the coupling cavity 11 , and inserted into the second guide sleeve 24 until the first wire 12 passes through, for example, the first suction nozzle 14 is held in place on the opposite side of the coupling cavity 11.

[0021] Vice versa, the second wire 15 from the reel 16 is introduced into the device 10 through the guide sleeve 21, through the coupling cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com