Base type non-metal water tap

A faucet, non-metallic technology, applied in the field of faucets, to achieve the effect of less man-hours, fast processing speed and improved firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

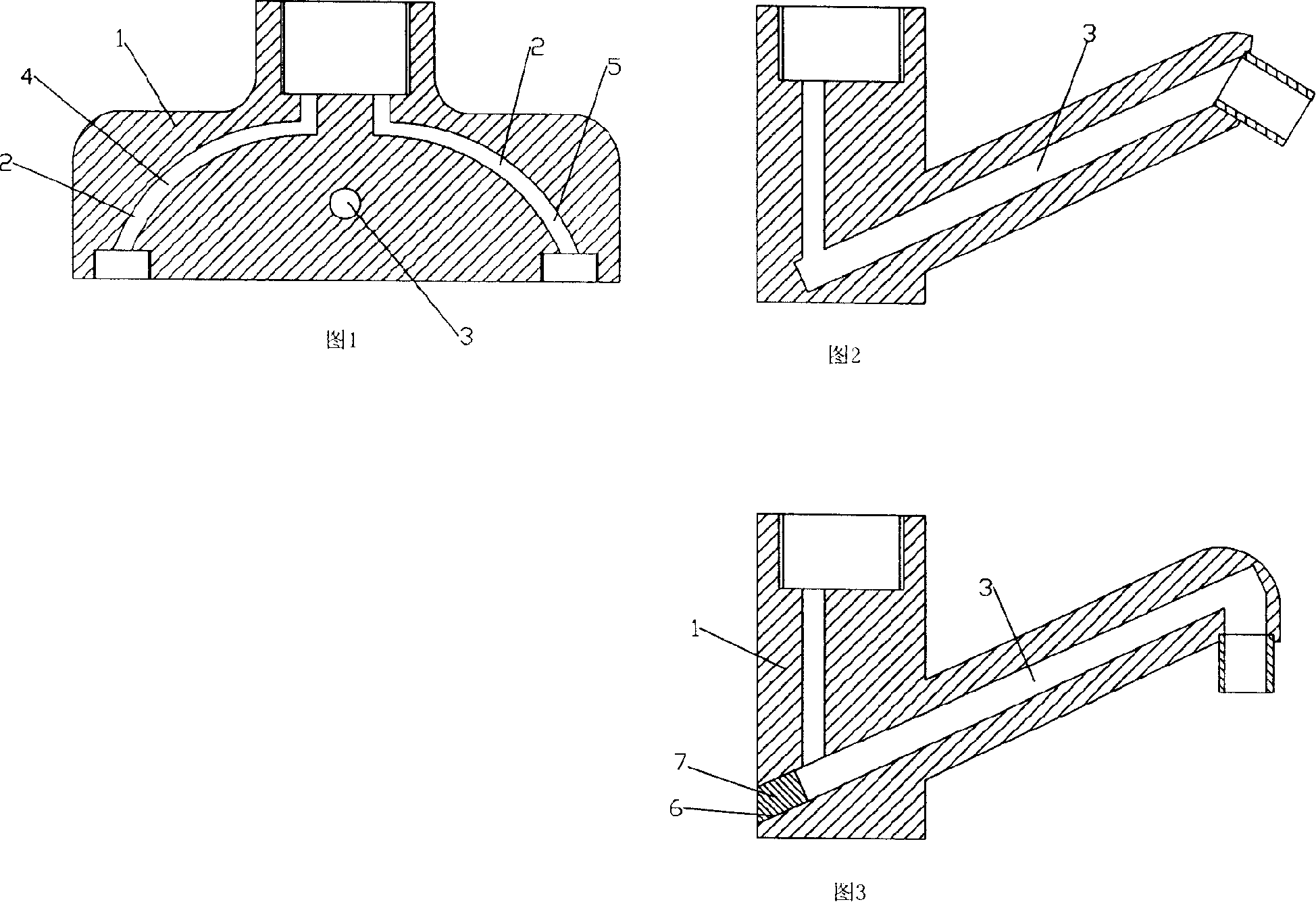

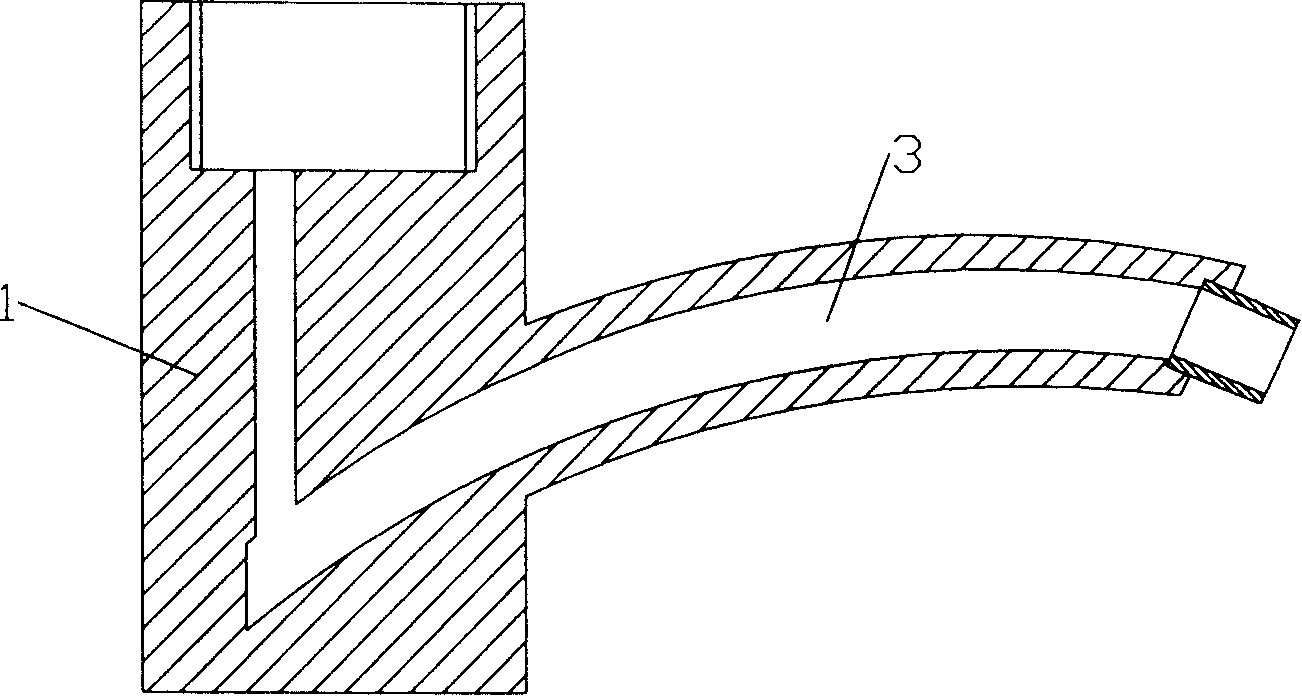

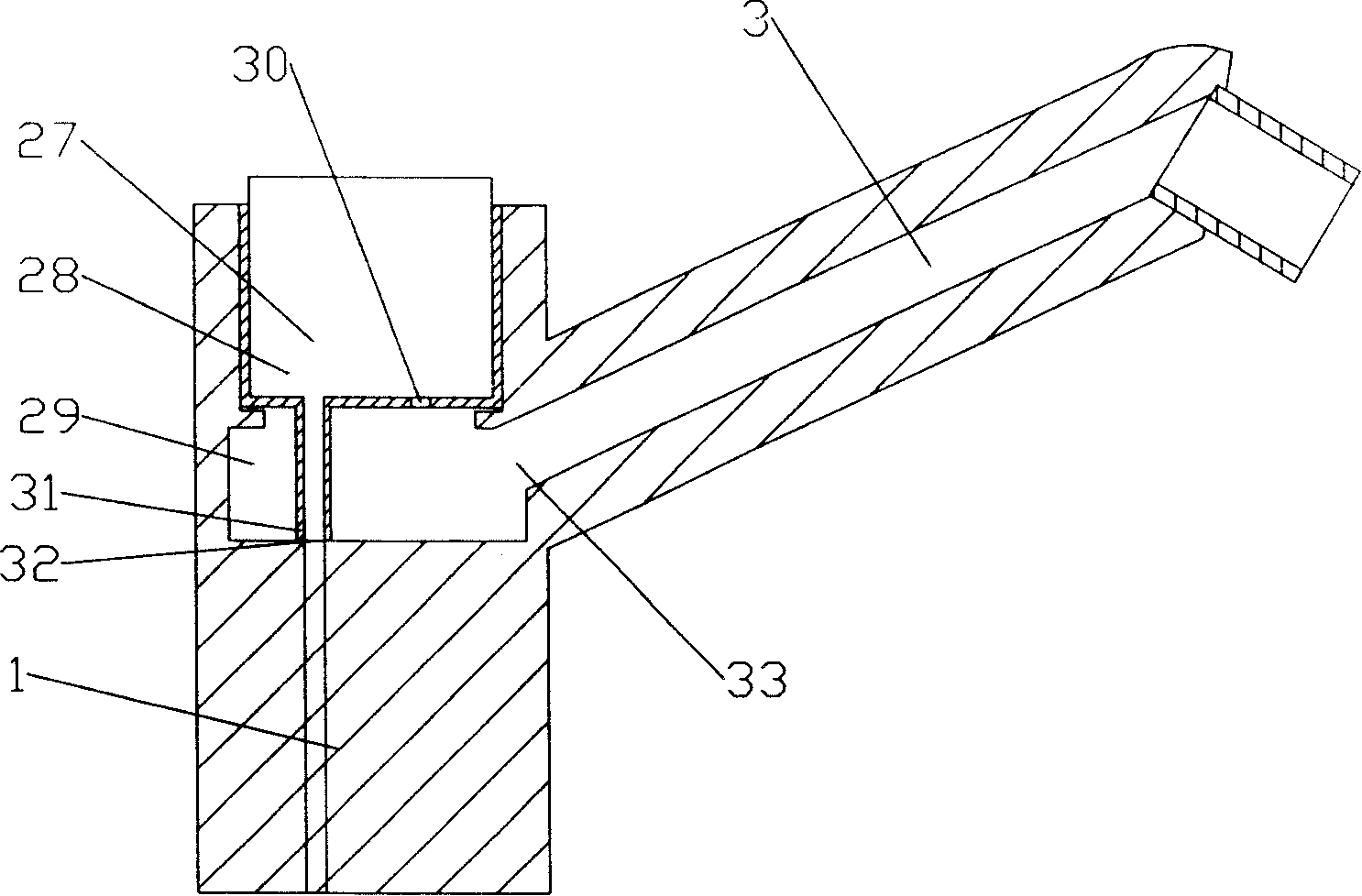

[0016] As shown in Figures 1 and 2, the first embodiment of the seat type non-metallic faucet of the present invention includes a faucet main casing 1, and the faucet main casing 1 has a water inlet channel 2 and a water outlet channel 3, and the water inlet channel 2 includes the cold water inlet channel 4 and the hot water inlet channel 5, the cold water inlet channel 4 and the hot water inlet channel 5 are equipped with water inlet joints, the cold water inlet channel 3 and the hot water inlet channel 4 both include a smooth and excessive arc channel, the water outlet channel 2 is arranged horizontally and straightly. In this embodiment, the cold water inlet channel 3 and the hot water inlet channel 4 are arc-shaped channels except for the parts connected to the water inlet joints, wherein the upper ends of the arc-shaped cold water inlet channel 3 and the hot water inlet channel 4 are respectively connected to the The water inlet hole of the valve seat arranged vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com