Panel detector and its detection method

A panel detection and panel technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of complex mechanism arrangement, high equipment cost, and space occupied by double transmission mechanisms, so as to simplify mechanical design and reduce equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

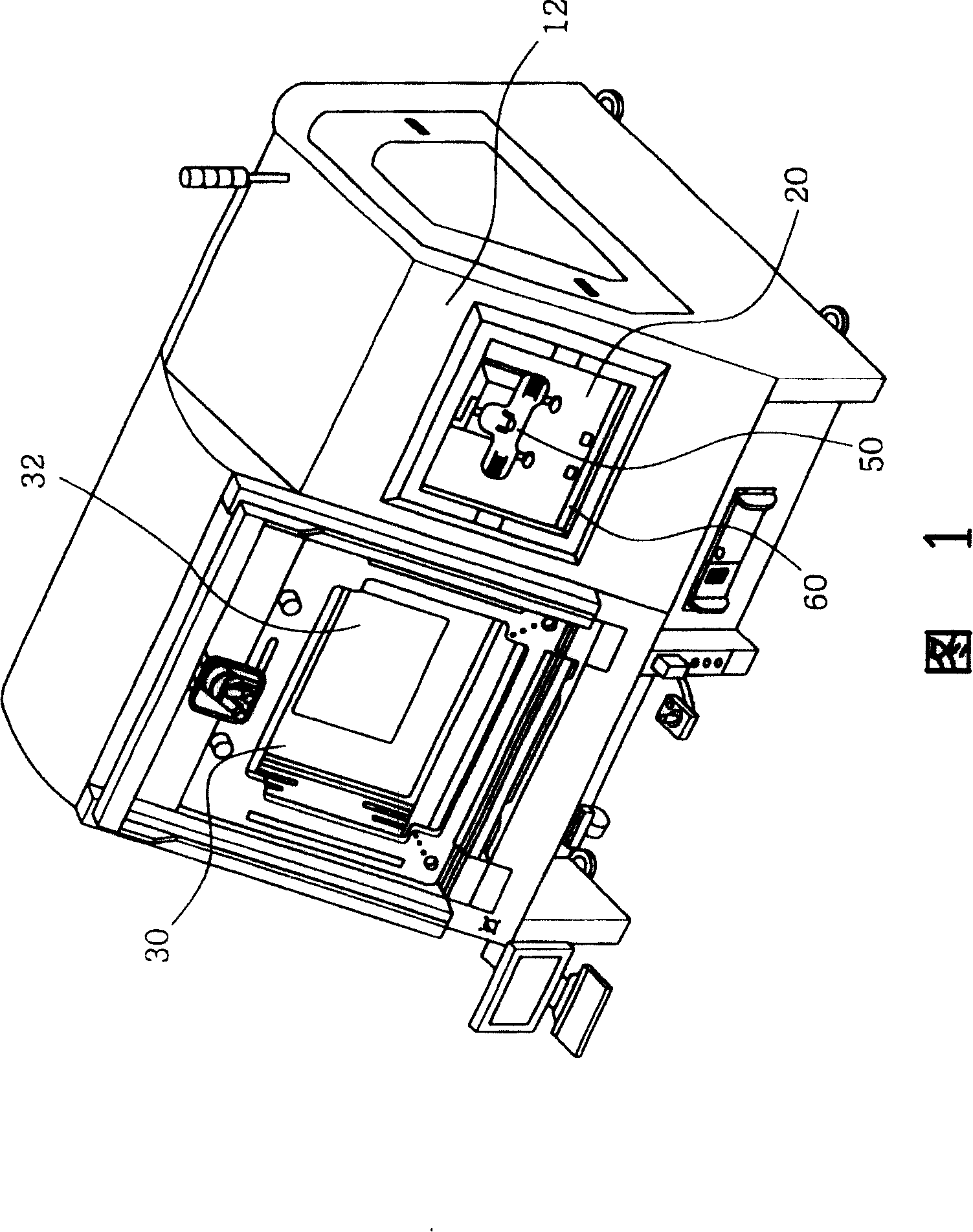

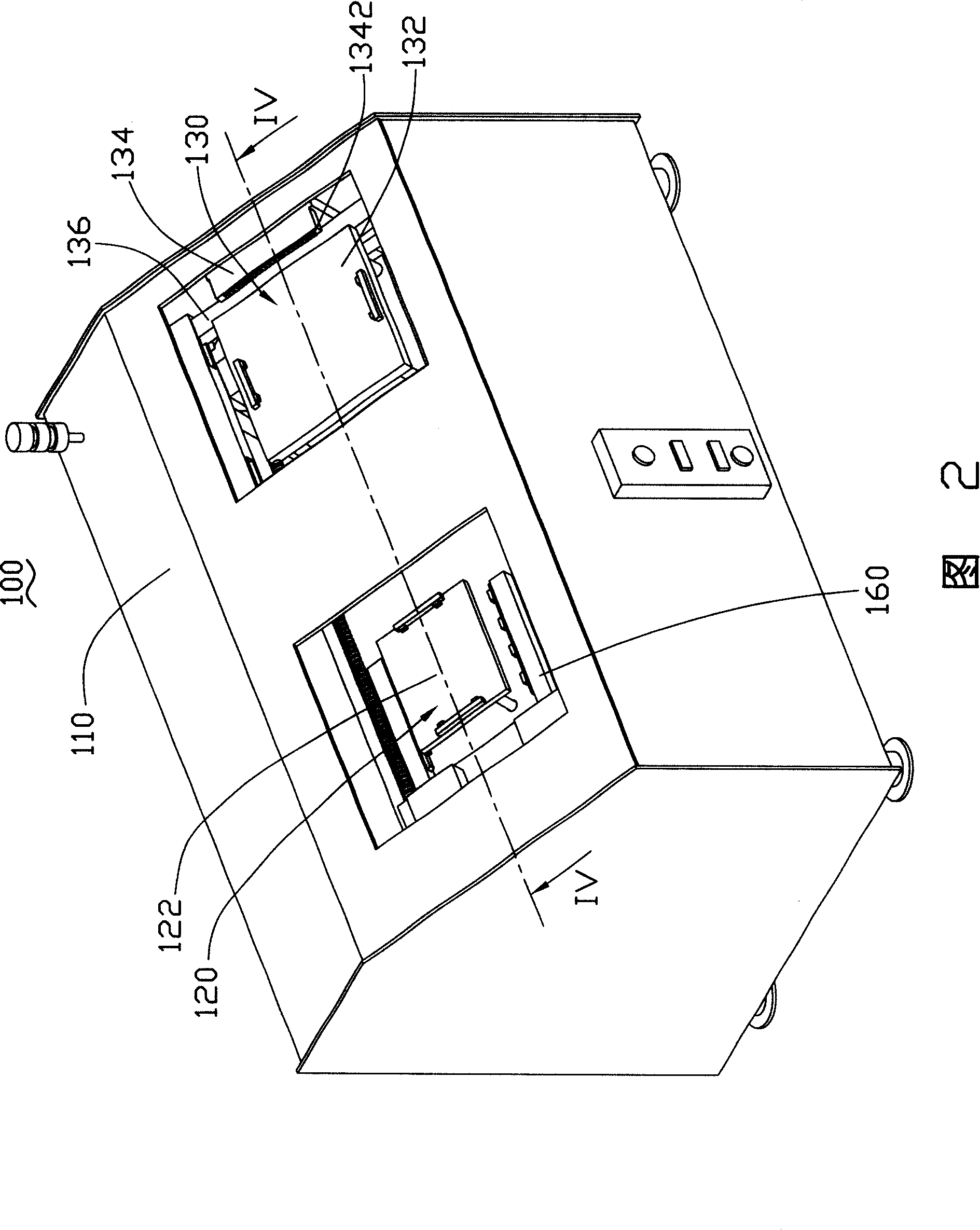

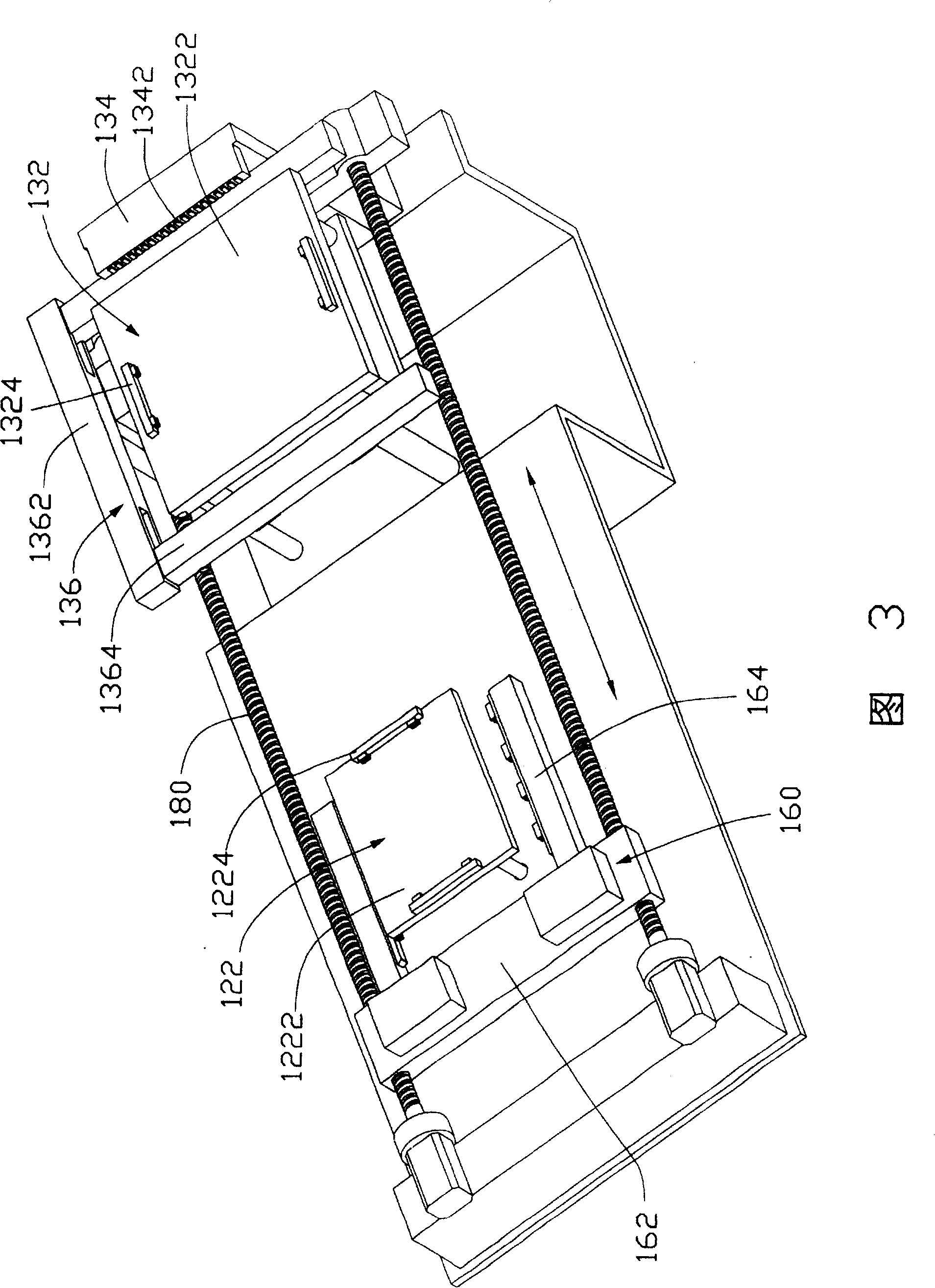

[0017] Referring to FIG. 2 , the panel detection device 100 provided by the embodiment of the present invention includes a housing 110 , a pick-and-place part 120 and a detection part 130 arranged on the housing 110 , and the A pre-clamp mechanism 122 , a detection platform 132 , a detection mechanism 134 , a buffer mechanism 136 , and a transfer mechanism 160 . The pre-clamping mechanism 122 is disposed on the pick-and-place portion 120 . The detection table 132 , the detection mechanism 134 and the buffer mechanism 136 are installed in the detection part 130 .

[0018] 3 and 4, the pre-clamping mechanism 122 can move up and down in a direction substantially perpendicular to the panel conveying direction of the conveying mechanism 160 (as shown by the double-headed arrow in FIG. 3 ), so as to move the panel to be detected Transport to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com