Lead member and boding method thereof and nonaqueous electrolyte electricity storing device

A technology of lead components and components, applied in hybrid capacitor electrolytes, electrolytic capacitors, hybrid capacitor electrodes, etc., can solve the problems of large-scale equipment, complicated operation, poor manufacturing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

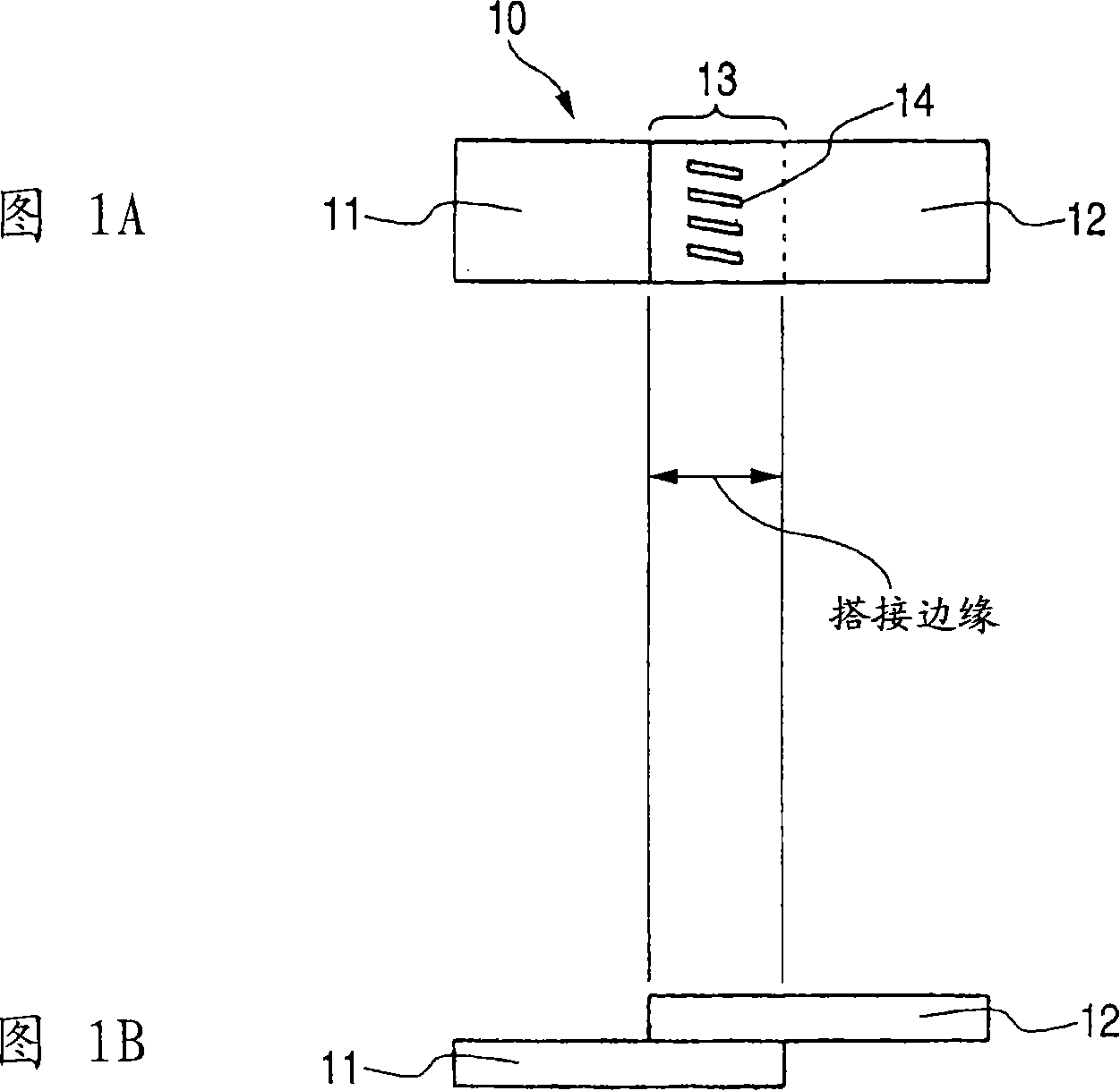

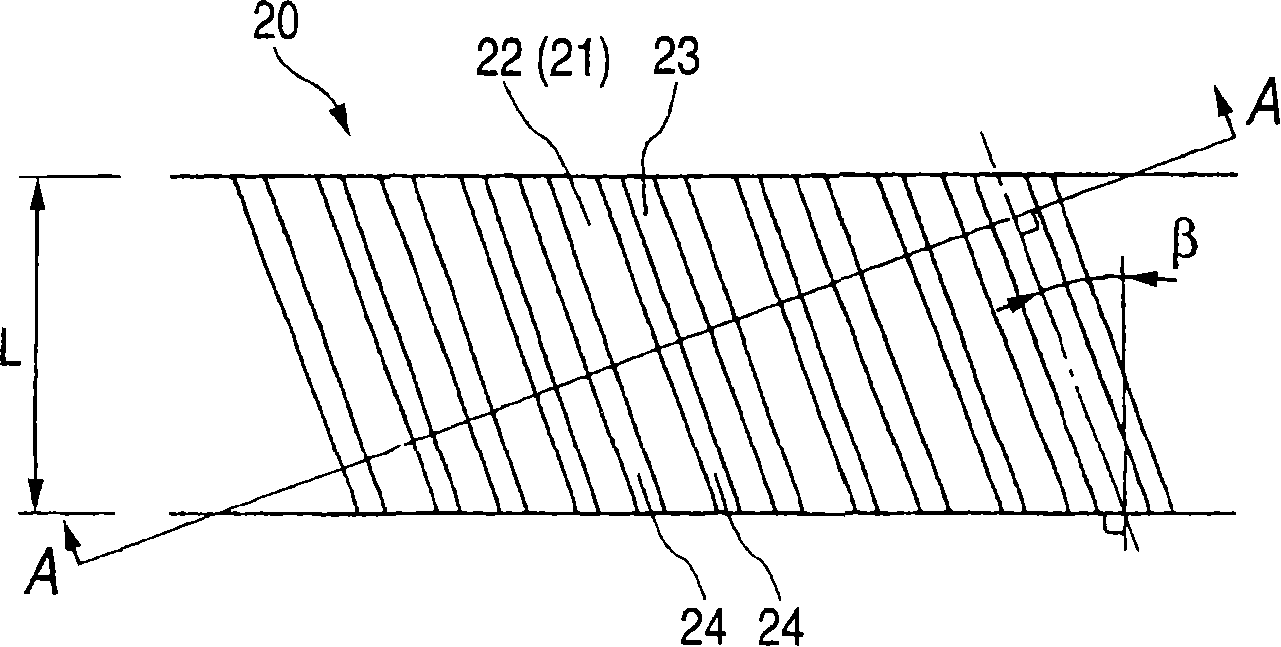

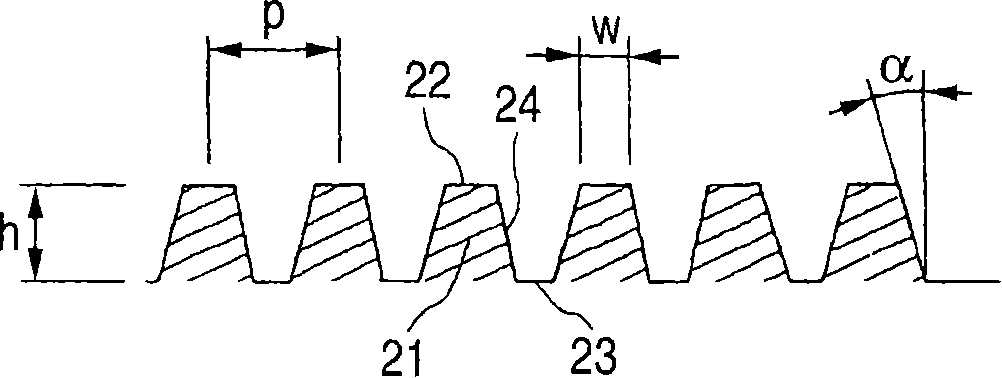

[0164] As an example of pressure bonding, an aluminum plate of 0.2 mm x 50 mm x 60 mm and a nickel-plated copper plate having the same dimensions were prepared. The aluminum plate and the nickel-plated copper plate are partially overlapped, and the overlapped portion is subjected to cold pressure welding. A mold consisting of a mold with a protruding part and a flat mold is used for pressure welding. In molds, there are three types of patterns for molds with protrusions. The first type of pattern is a straight die. This die is a die for pressing the overlapping portion into a linear shape in the width direction. The second die is a lengthwise tooth die. The die is constituted by a shape in which a plurality of elliptical protruding portions are arranged, and the respective protruding portions are arranged such that the longitudinal direction thereof coincides with the longitudinal direction of the lead member. The third mold is a helical tooth mold. The die is constituted...

Embodiment 2

[0193] Next, the shape of the helical tooth mold used in Example 1 was changed, and cold welding and planarization similar to Example 1 were performed by this mold. The mold used in this example is a boat mold in which both ends of the protrusion are formed into a convergent shape. This die is similar to the helical tooth die in other descriptions except that both end portions of the protrusion are formed into a convergent shape.

[0194] When cold welding is performed by using this boat-shaped die, the cold press welding mark is in a mode of transcribing the shape of the protruding part of the die, similar to the helical tooth die. However, after the planarization, it can be seen that the opening width of the cold-welding trace decreases not only at the middle portion in the longitudinal direction of the cold-welding trace, but also substantially over its entire length. Therefore, it seems that in the case of using a boat-shaped mold instead of a helical tooth mold, the area...

Embodiment 3

[0196] Next, lead members of the present invention by cold welding and lead members for comparison by ultrasonic welding were manufactured, and their tensile properties and electrical properties were observed.

[0197] Also in this case, a nickel-plated copper plate and an aluminum plate similar to Example 1 were prepared, and their overlapping portions were subjected to cold welding or ultrasonic welding. The die used in the cold welding was the same die as the helical die in Example 1. On the other hand, ultrasonic welding was performed by constituting a joint area of 12 mm x 3 mm x 2 parts. Also cold welded samples were flattened by a pair of planar dies. Also, the planarization conditions are similar to the working conditions of Example 1.

[0198] The tensile properties were measured by holding both ends of the provided lead member with a tensile tester, and the joint strength was constituted from the tension at the time point when the nickel-plated copper plate and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com