Method of and equipment for manufacturing a fibrous web formed at high consistency

A technology for manufacturing fibers and fiber webs, which is applied in papermaking, paper machines, textiles, and papermaking, and can solve problems such as uniform distribution of fibers and difficulty in forming a properly oriented web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

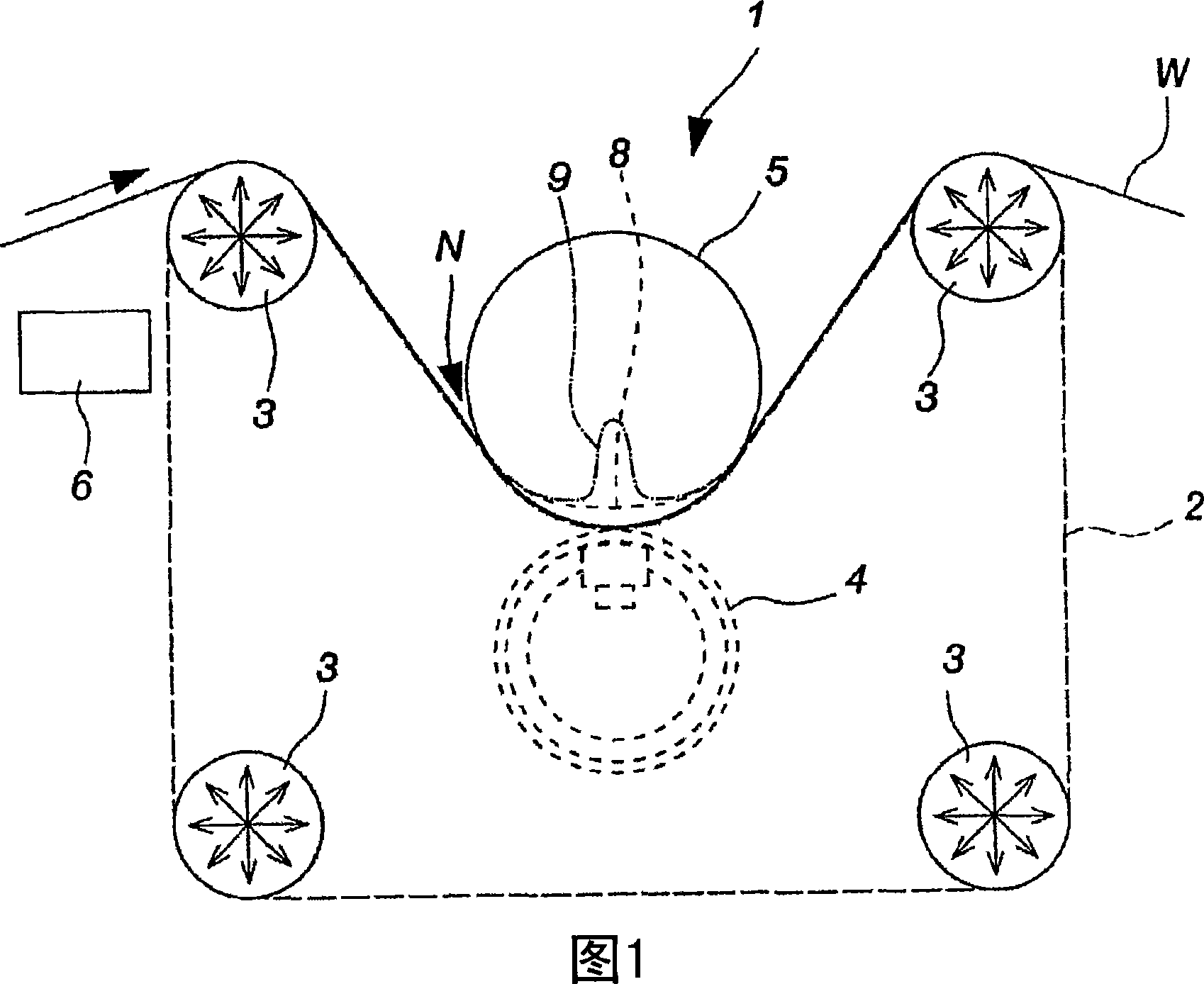

[0025] FIG. 1 shows a possible embodiment of a pressure and heat treatment device for forming a fibrous web W. As shown in FIG. This embodiment comprises a belt calender 1 having a metal belt 2 extending around a plurality of guide rollers 3, at least one of which is adapted to movably adjust the tension or tension of the belt 2 . The forming belt 2 runs through rollers 5 and forms a pressurized and heat-treated zone N between the belt 2 and the rollers 5 . The fibrous web W to be formed travels through the pressure and heat treatment zone N while being formed under pressure momentum and temperature as a function of time. The belt 2 can be heated or cooled by the heating / cooling device 6 . The dotted line 9 in Figure 1 shows the pressure that develops when the press roll 4 is mounted inside the loop made of the forming belt 2, the roll 4 acting as a pressing element and pressing the belt 2 against the roll 5 is applied Greater pressure is provided in the nip of the press an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap