Plasma display panel

A wrench and input shaft technology, applied in the field of wrenches, can solve the problems of being close to the outside of the rod, making it difficult for the staff to confirm the operation, and difficult to tighten the target screw, etc., to achieve the effect of great convenience and easy installation/separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

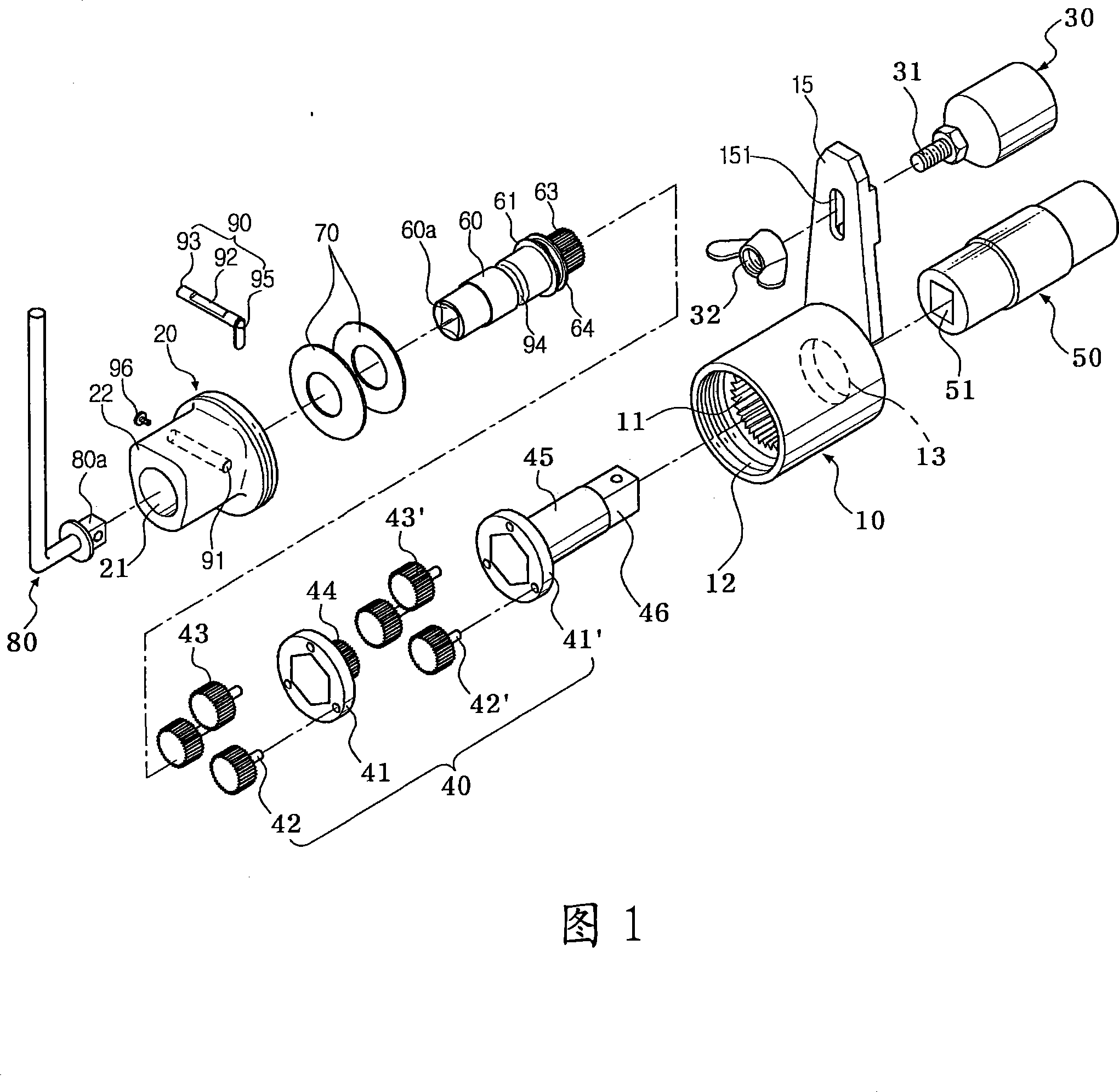

[0051]The tire wheels of a row of vehicles are fixed to the hub, and the product of the present invention is used when installing or removing fixing nuts on various fixing screw shafts protruding from the hub. When installing the set screw, it is not based on vision, but the idling state of the transmission gear, and immediately senses whether the set screw shaft is fully tightened, greatly improving convenience. In addition, clockwise or counterclockwise rotation can be used, making it easy to install or separate the fixing nut.

[0052] The wrench in the first practical operation example of the present invention is as Fig. 1 or Fig. 10, comprises cylindrical cover 10 and cap 20, the earliest input shaft 60, transmission gear 63, the earliest output shaft 45, elastic means 70, the first input shaft Stop / solve tool.

[0053] One side of the cover 10 is formed with an opening 12, and the other side has a support wall 14 having a diameter smaller than that of the opening of one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com