Marking instrument

A technology for marking and tools, which is applied to writing utensils, printing, and ink pens with ink storage tubes in the pen barrel, etc. It can solve problems such as ink leakage, marking tool leakage, and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

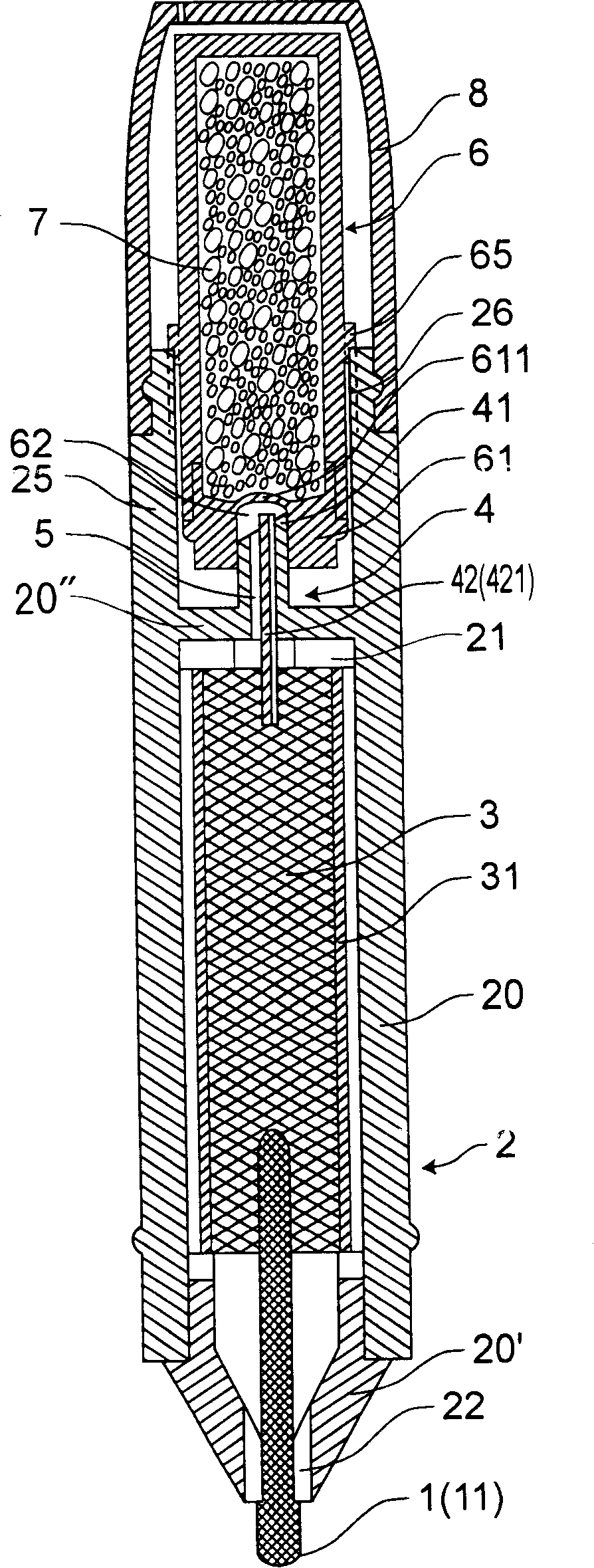

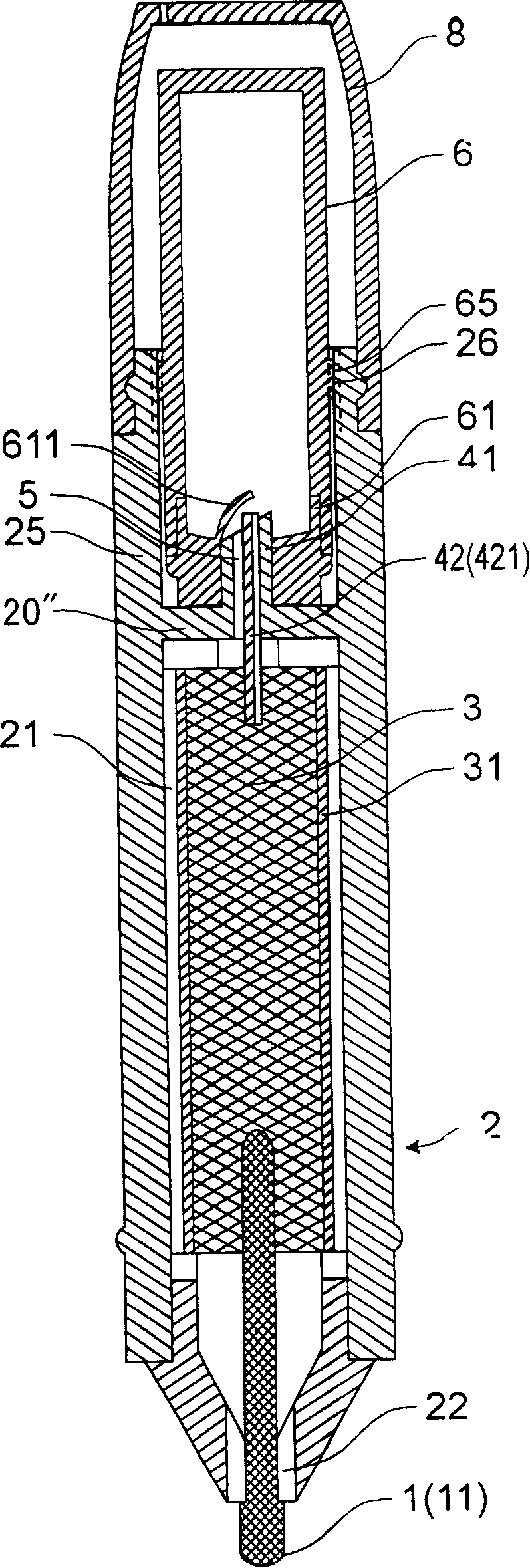

[0140] Embodiment one: see figure 1 and figure 2 , marking nib 1, used to apply marking ink 7 to a surface, ink storage chamber 2, used to provide marking ink to marking nib 1, also includes ink-containing device 3 with adsorption capacity, in the ink-containing device 3. A jacket 31 is arranged outside the ink-containing device 3 to control the gap between the ink-containing device 3 and the ink-containing ink. The ink reservoir 6 is located above the ink-containing device 3, which increases the ink capacity of the marking tool and prolongs the writing time; the additional ink reservoir 6 adopts a fully enclosed structure to ensure that the additional ink reservoir 6 will not leak ink The liquid phenomenon; the marking ink can be stored for a long time and is not easy to be dried and reduced, which further prolongs the writing time. see figure 1 At least part of the bottom 611 of the bottom 61 of the additional ink reservoir 6 is made into an integral structure with the b...

Embodiment 2

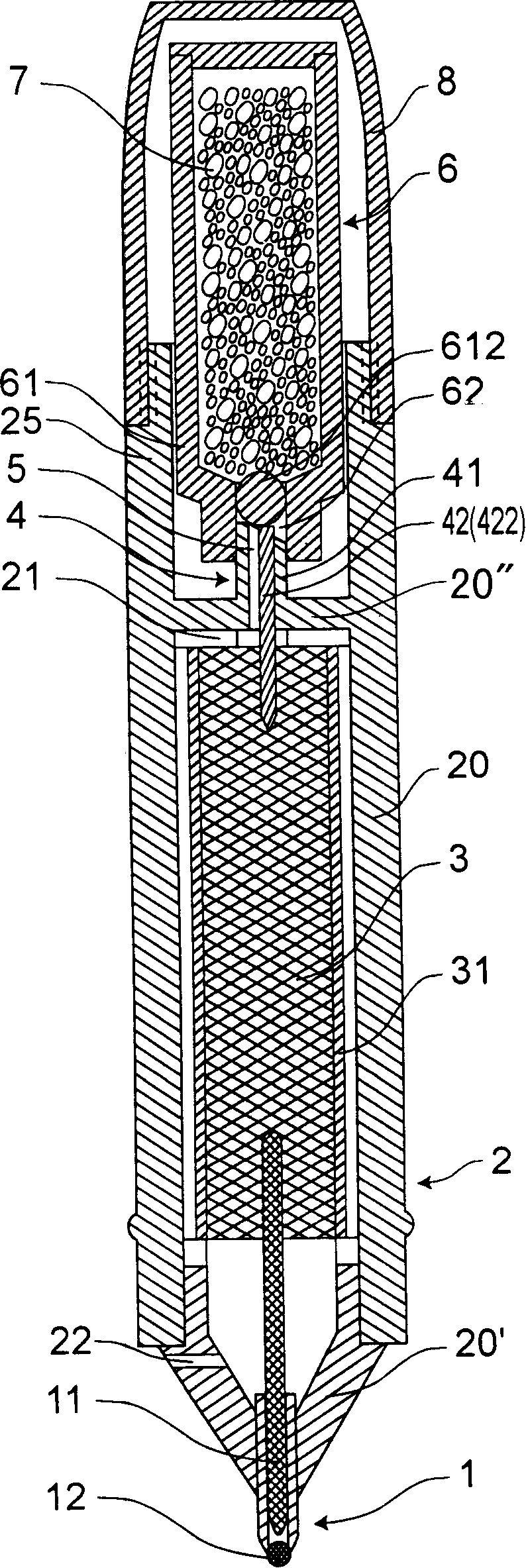

[0153] Embodiment two: see image 3 , In the ink storage chamber 2, an ink-containing device 3 with a gap and adsorption capacity is set. The opening device 4 is arranged on the top 20 " of the ink storage chamber 2. The opening device 4 includes an opening member 41 and an ink introduction device 42. The ink introduction device 42 is arranged in the opening member 41. The ink introduction device 42 can include a The ink-leading core 422 of the ability to draw ink (absorption), the ink-leading core 422 is connected with the ink-containing device 3, and is used to guide the marking ink in the additional ink tank 6 to provide the ink-containing device 3. The ink-leading core 422 has at least Part of it is exposed or exposed on the inlet of the opening member 41, so that the opening member 41 opens the additional ink reservoir 6 to facilitate the introduction of the ink core 422 to guide the marking ink in the additional ink reservoir 6 to supply the ink-containing device 3. The ...

Embodiment 3

[0160] Embodiment three: see Figure 5 , this embodiment and image 3 Similar, the main difference is: at least part of the surface of the additional ink reservoir 6 is provided with thread 651, and the thread 26 is also provided on the sleeve 25 to connect with the thread 651, the user can only rotate the additional ink reservoir 6 Only by making the additional ink reservoir 6 rotate radially relative to the opening member 41 can the opening device 4 be opened and the marking ink 7 in the additional ink reservoir 6 be guided to the ink-containing device 3. The operation is simple, the use is safe, and the Inadvertently or when children are playing, directly open the marking ink 7 in the additional ink tank 6 to supply in the ink-containing device 3 containing the marking ink, and cause the marking ink in the ink-containing device 3 to exceed the ink-containing device 3 The phenomenon of dripping ink occurs due to the amount of adsorption it bears. Another main difference is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com