Method for measuring mechanical fatigue of steam turbine generator unit shaft system

一种汽轮发电机组、机械疲劳的技术,应用在发动机的测试、固体中的振动测量、机器/结构部件的测试等方向,能够解决汽轮发电机组轴系机械疲劳、没有提供机组轴系扭振保护与控制设备等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

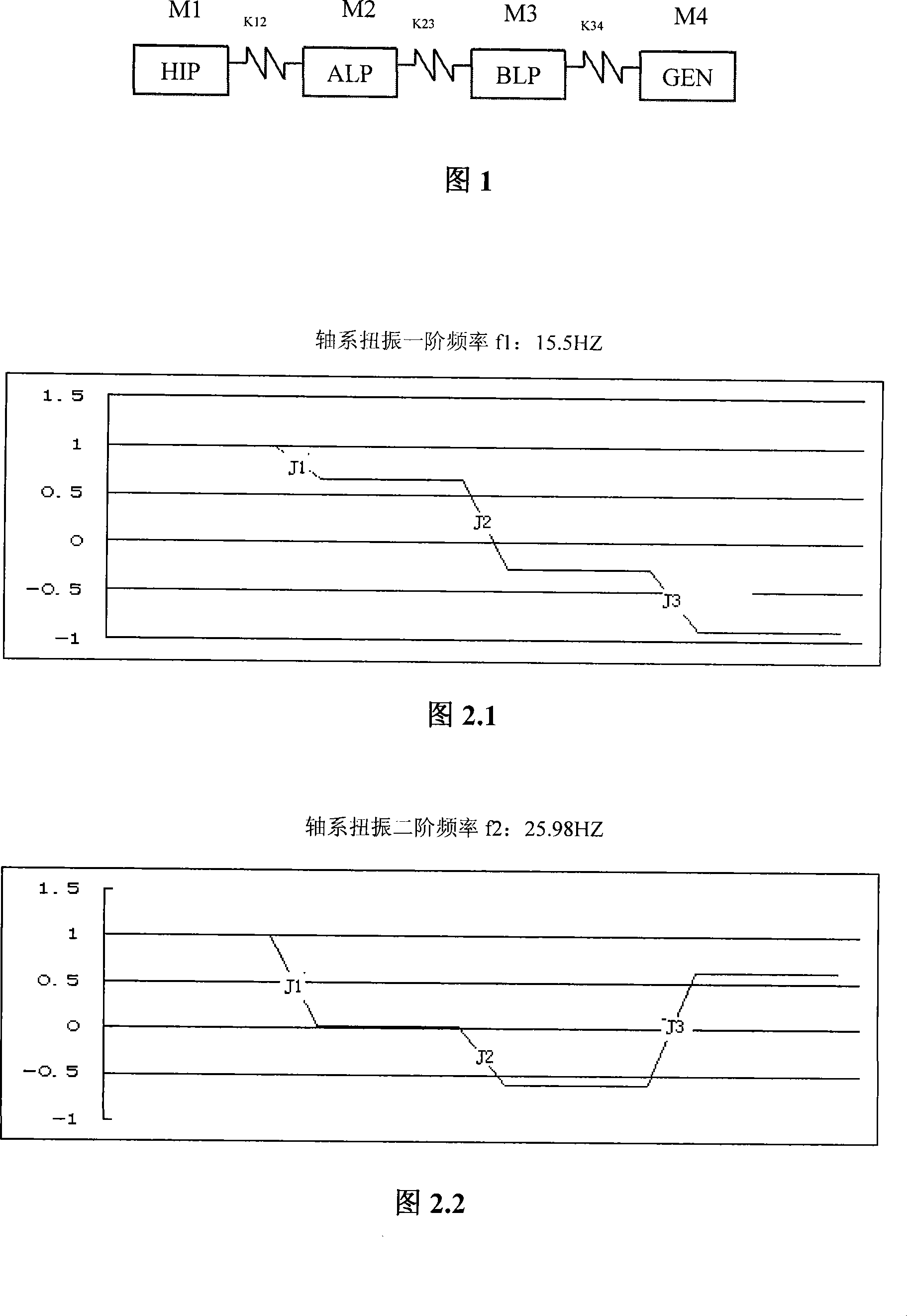

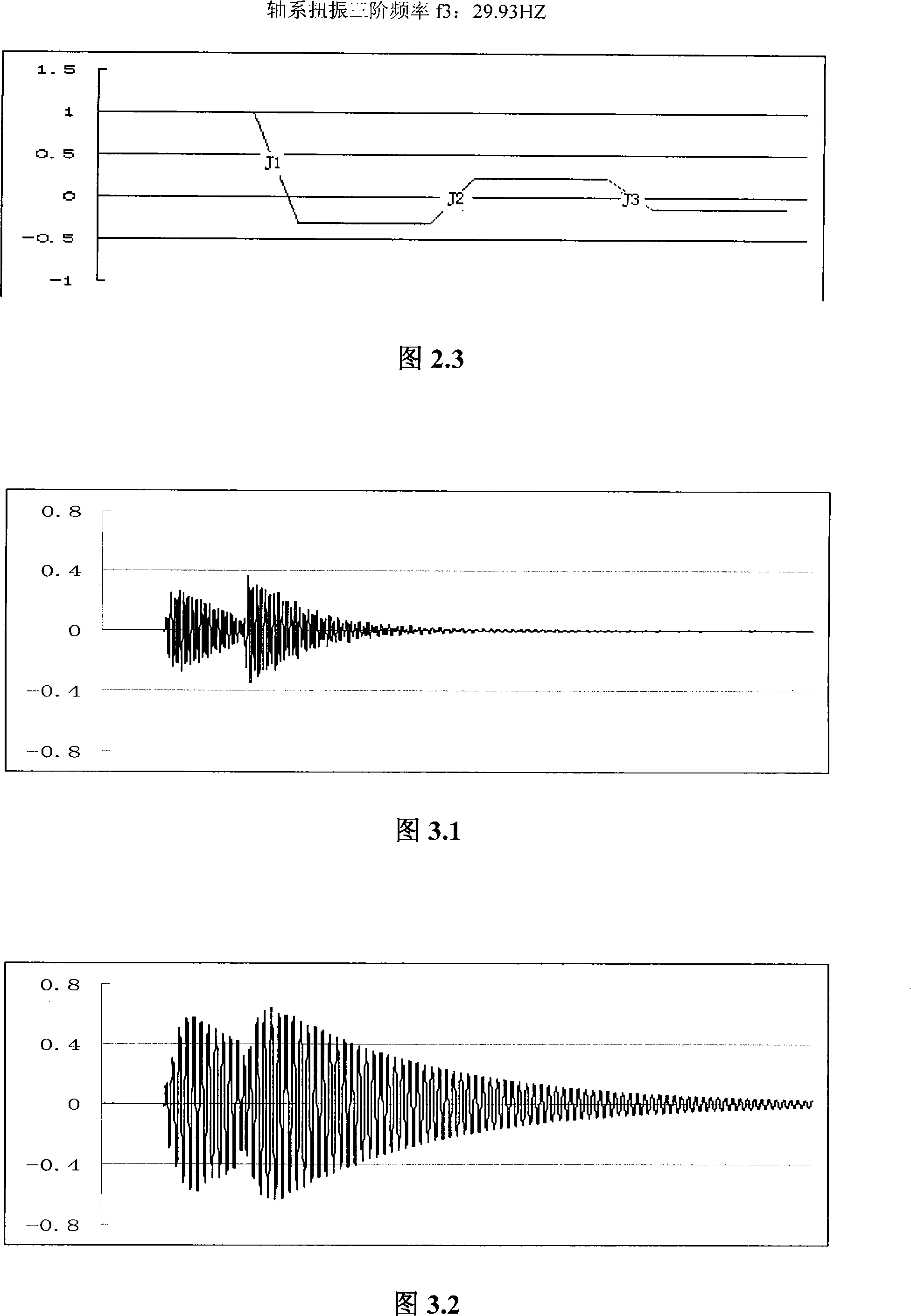

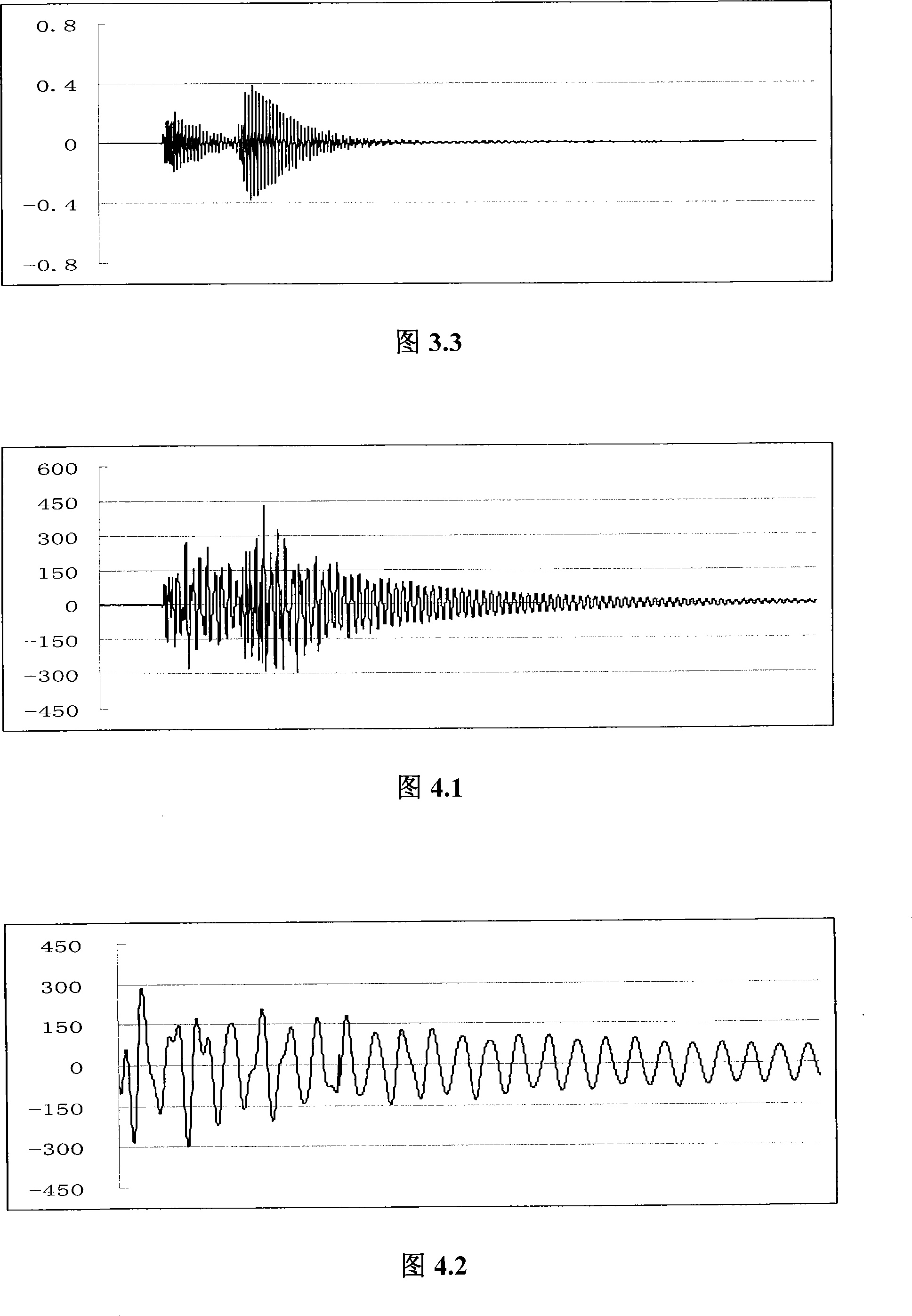

[0075] The present invention will be described in further detail below according to the accompanying drawings and embodiments.

[0076] The working process of the present invention is as follows: collecting the change amount of the angular velocity of the machine end, and demodulating the instantaneous value of each modal torsion angle of the machine end. According to the calculated modal frequency and mode shape curve, the torque generated by the input data at each calculation section of the shaft system is calculated, and the load-time history curve at each calculation section of the shaft system is obtained. Use the rainflow method to find the stress cycle, check the corresponding S-N curve to obtain the fatigue damage value corresponding to this cycle, and finally get the cumulative value of fatigue damage caused to each dangerous section of the shafting of the unit under a certain fault or disturbance, that is, the steam turbine power generation Mechanical fatigue of unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com