Lens module

A technology of lens module and lens barrel, applied in installation, optics, instruments, etc., can solve the problem of increasing the size of the camera

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

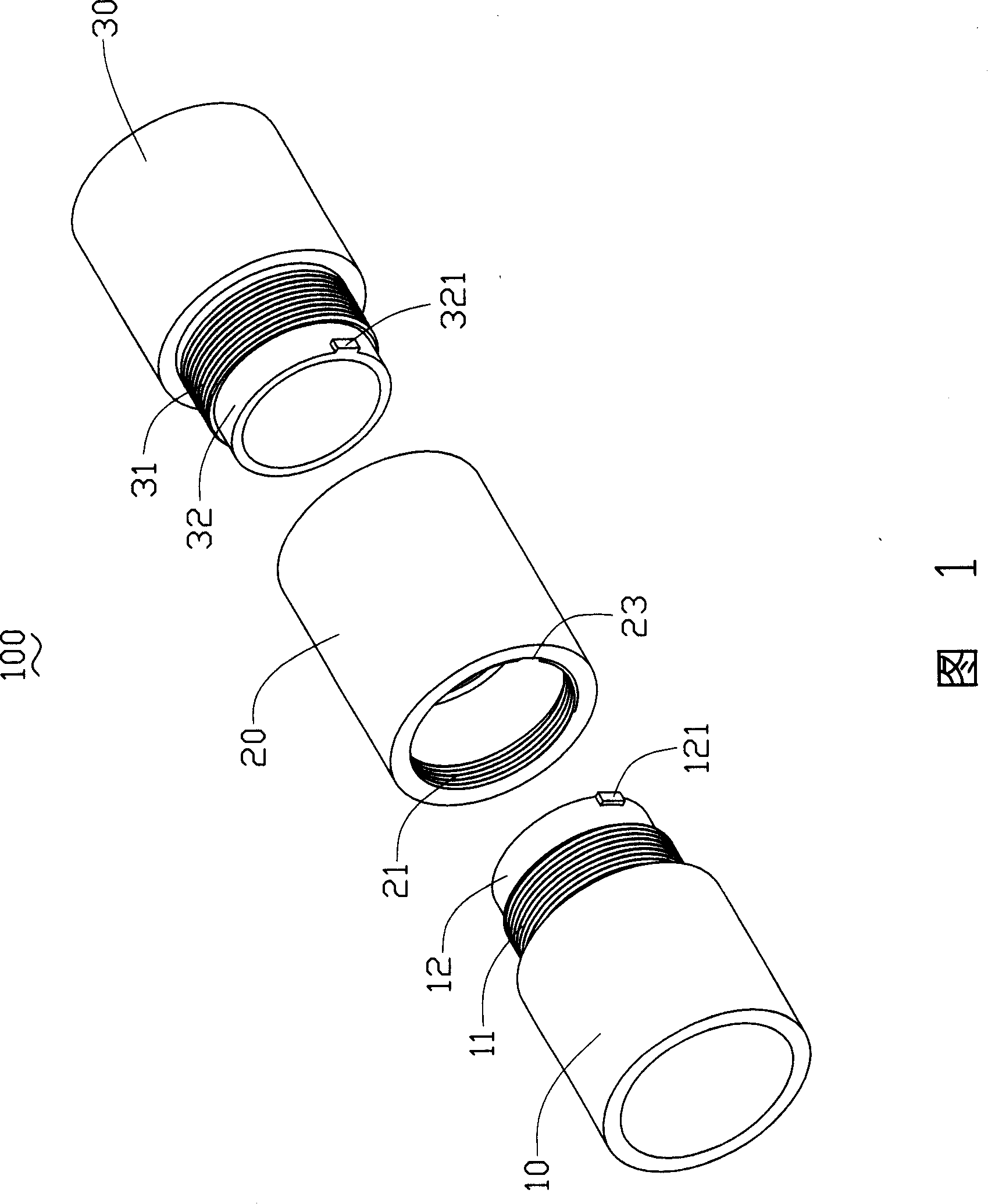

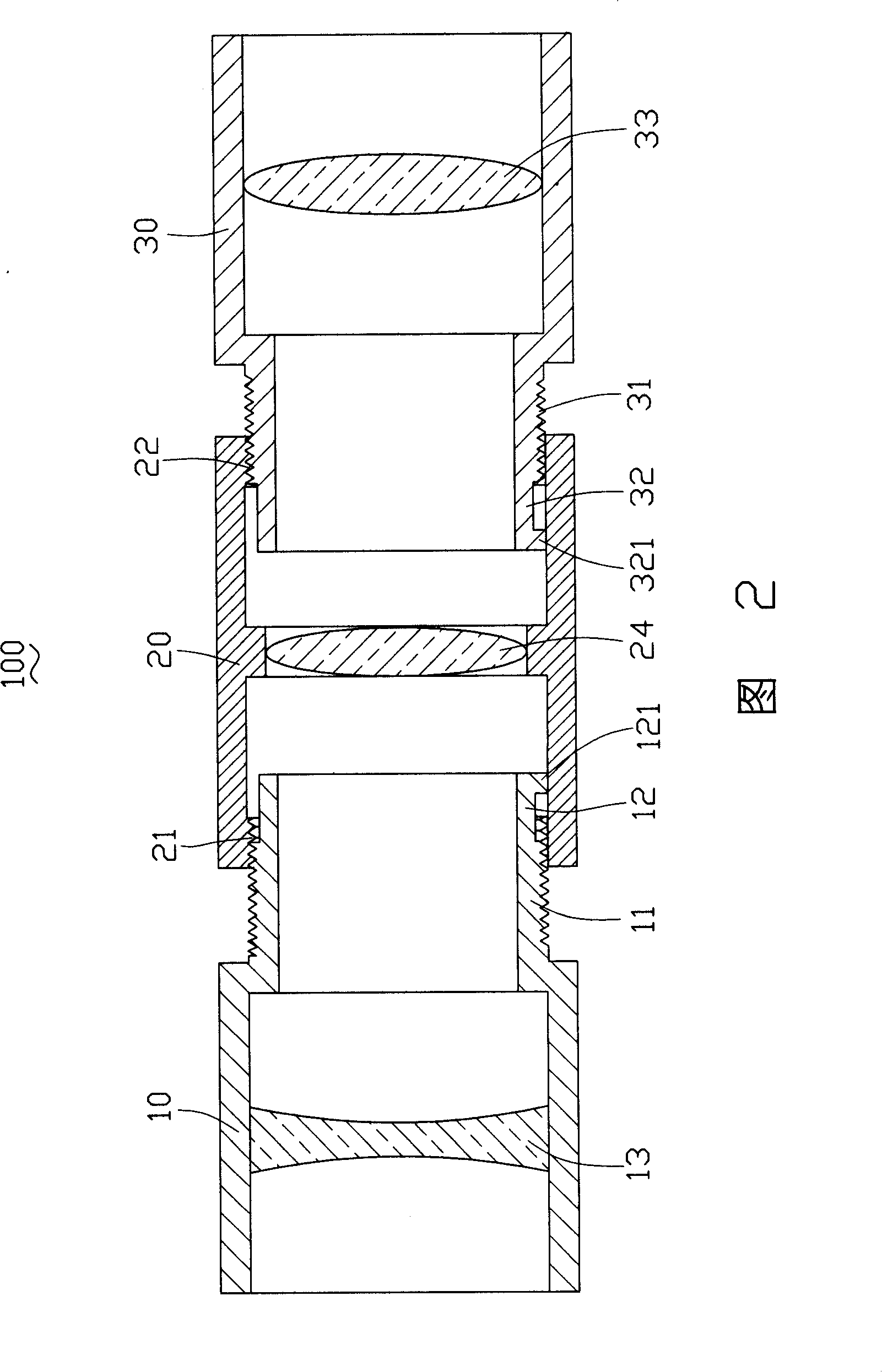

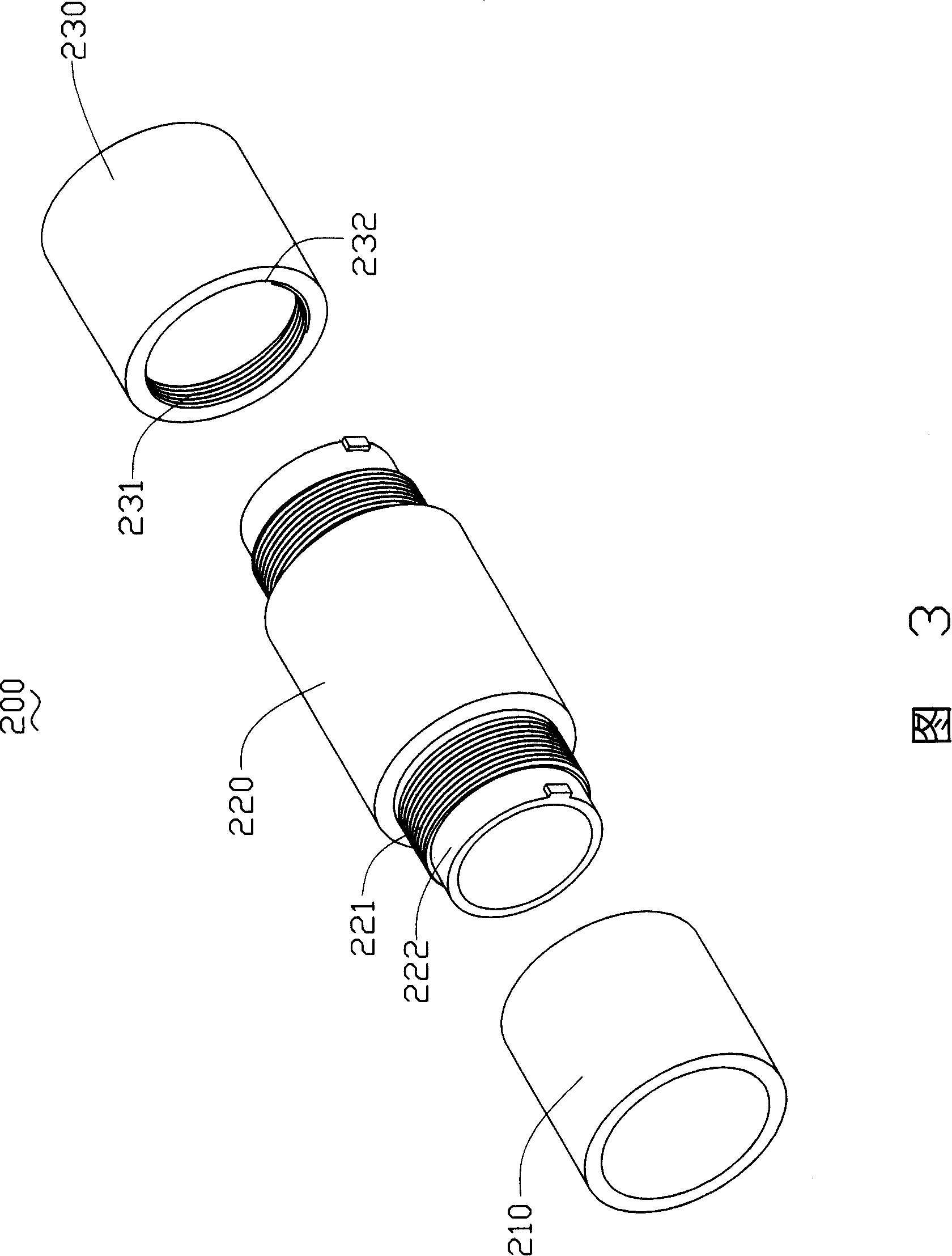

[0014] Referring to FIG. 1 and FIG. 2 , the lens module 100 provided by the first embodiment of the present invention includes a first lens barrel 10 , a second lens barrel 20 and a third lens barrel 30 . The second lens barrel 20 is disposed between the first lens barrel 10 and the third lens barrel 30 .

[0015] The first lens barrel 10 has an external threaded portion 11 and an engaging portion 12 extending from the external threaded portion 11 toward the second lens barrel 20 . The external thread portion 11 has an external thread, and the engaging portion 12 has a protrusion 121 extending radially along the first lens barrel 10 . It can be understood that there may be multiple protrusions 121 .

[0016] The third lens barrel 30 has an external thread portion 31 and an engaging portion 32 extending from the external thread portion 31 toward the second l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com