Mixing device for tub

A bath and fluid mixing technology, applied in bathing devices, applications, bathtubs, etc., can solve the problems of not being able to mix gas, not obtaining a warm bath effect, etc., and achieve the effect of avoiding the decline of the dissolved amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

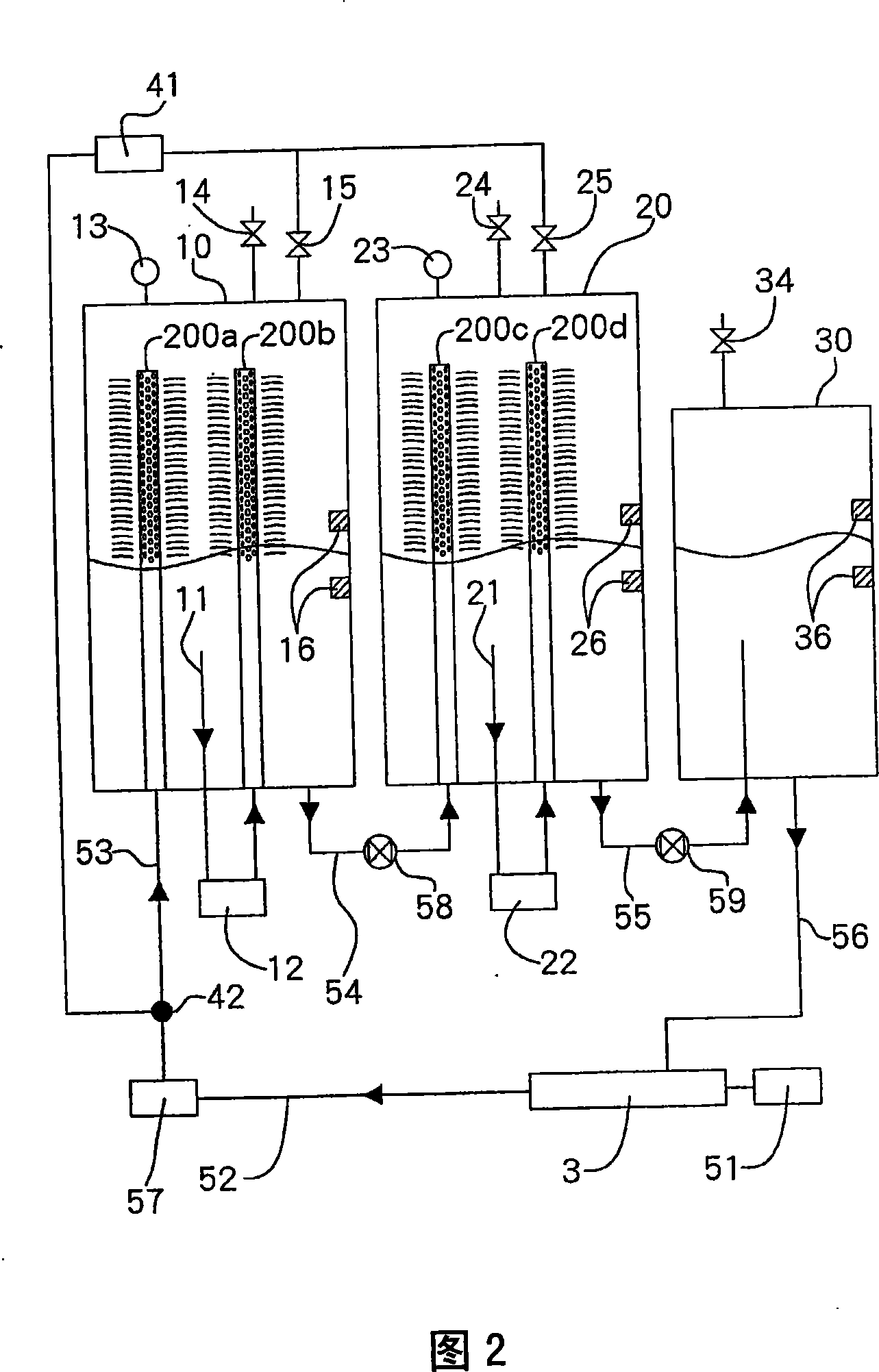

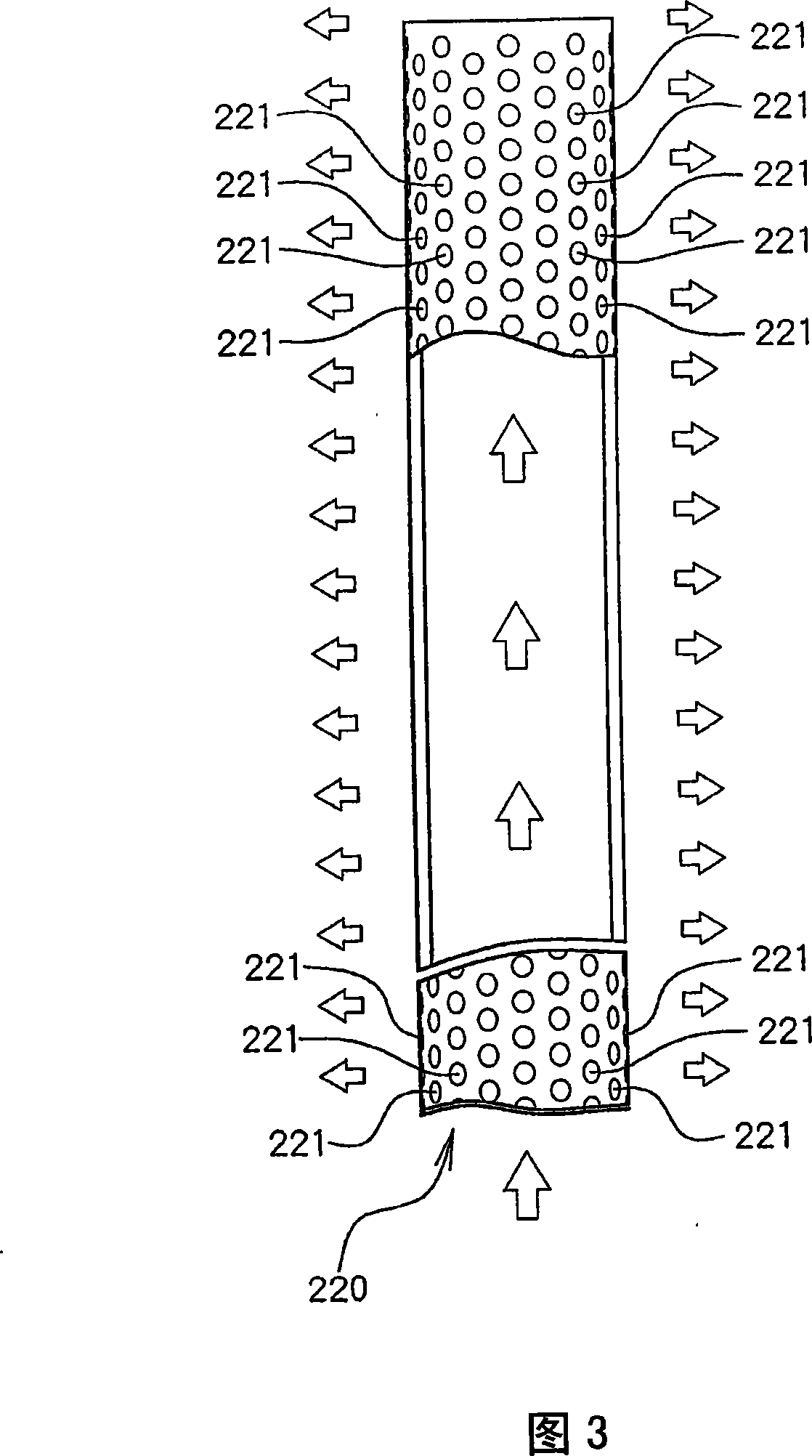

[0150]A bath mixing apparatus for supplying a mixed liquid including a gas-mixed liquid to a bath, said bath mixing apparatus having: (i) a first mixing chamber having a supply line through which the mixed liquid passes a supply line is fed for storing the mixed liquid at the bottom and having a first internal pressure maintained at a level above atmospheric pressure; (ii) a second mixing chamber having a supply line through which the mixed liquid passes A supply line is supplied for storing liquid at the bottom, and has a second internal pressure maintained at a level equal to or higher than atmospheric pressure but lower than the first pressure in the first mixing chamber; (iii) for The mixed liquid is circulated in the order of the first mixing chamber and the second mixing chamber through the chamber, and then it is returned to the bath; (iv) a liquid supply part for supplying the liquid to a tank comprising the corresponding bath, the first mixing chamber and the second mi...

Embodiment 2

[0152] The bath mixing apparatus according to Embodiment 1, further comprising: (I) a gas supply line that connects the first and second mixing chambers to the gas supply part via a valve; (II) a sensor that measures pressure in the chamber; (III) a control part that controls the opening / closing of the valve based on the pressure value detected by the sensor.

Embodiment 3

[0154] The bath mixing device according to embodiment 1 or 2, wherein the metering valve or the choke valve is arranged between the first mixing chamber and the second mixing chamber, and between the second mixing chamber and the bath.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com