Bearing press-in device and method of use thereof

A press-in device and bearing technology, used in measuring devices, workpiece clamping devices, force/torque/work measuring instruments, etc., can solve the problems of uncontrollable press-in force, high product rejection rate, and inability to ensure accurate depth of bearings, etc. To achieve the effect of small positioning error, preventing leakage and misplacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

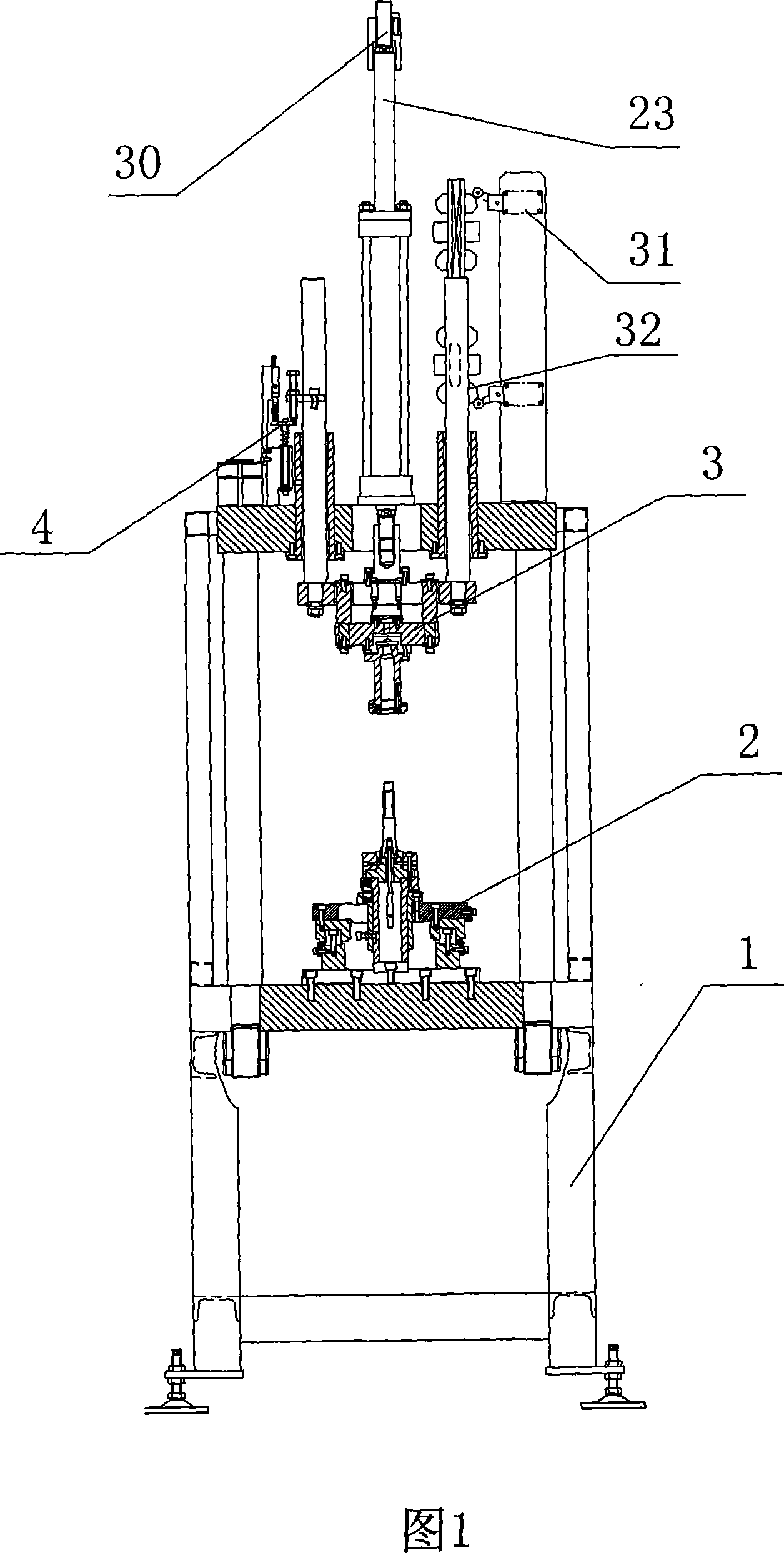

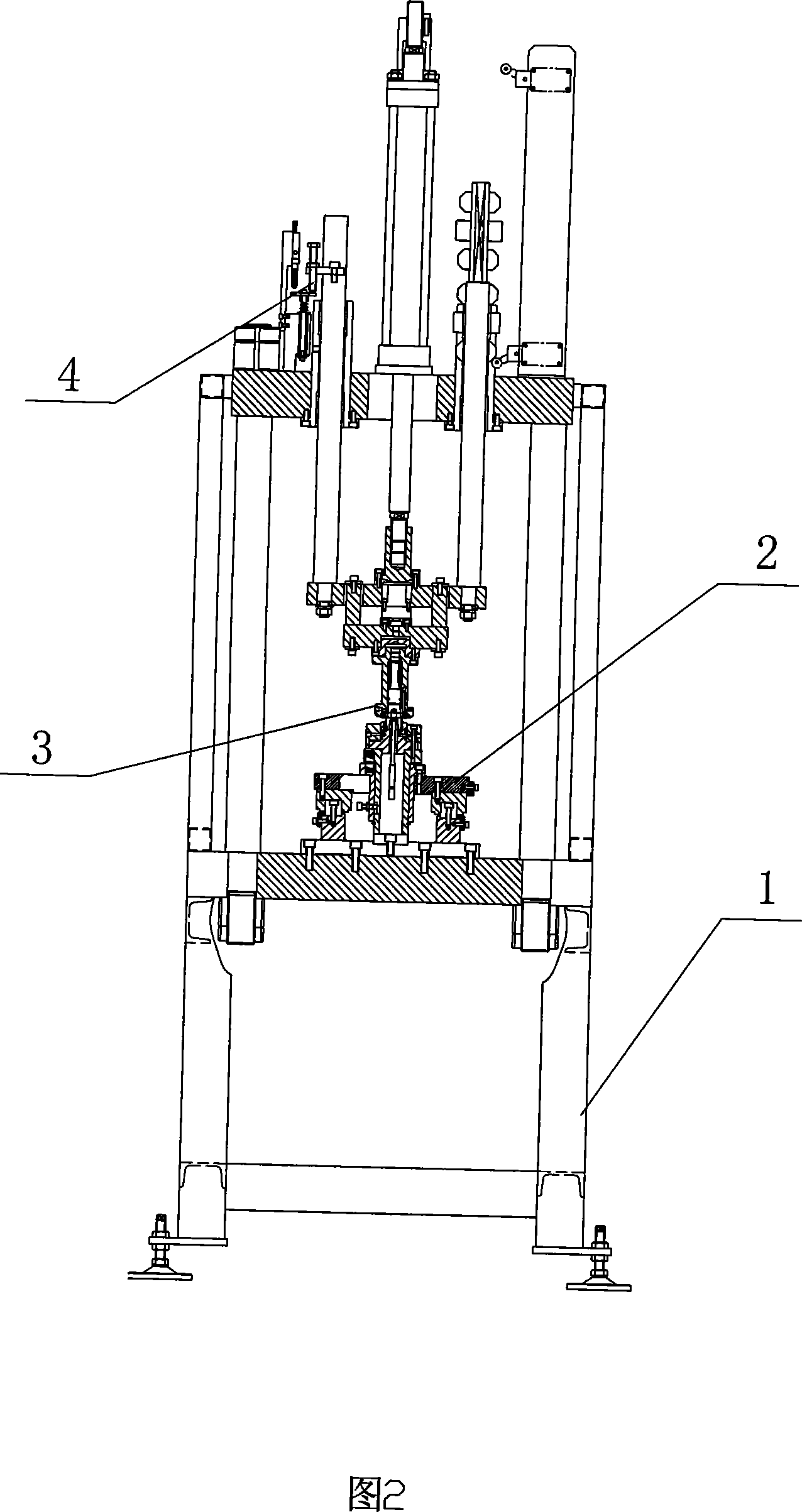

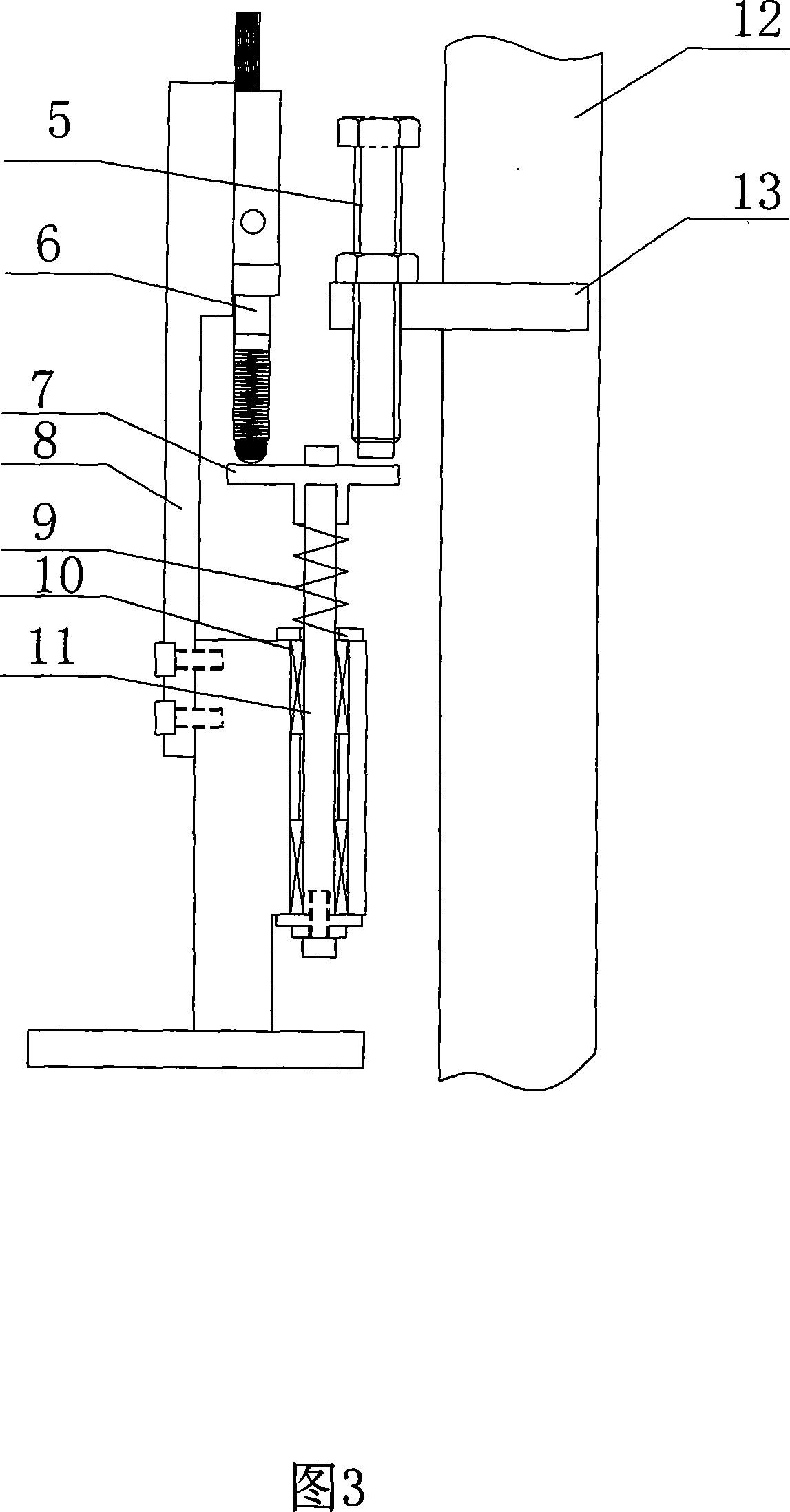

[0024] Please refer to Figures 1 to 5, the bearing press-in device of the present invention can be used to press the bearing 16 into the shaft 15, including the body 1, the hydraulic drive mechanism (not shown), and the oil cylinder installed on the body Guide rod 12, the detection device 4 that is used to detect bearing press-in depth, the force-measuring device that detects bearing press-in force, vacuum generator (not shown in the figure) and the press-in device that bearing 16 is pressed in.

[0025] Wherein, the press-in device includes an upper clamp 3 and a lower clamp 2, and the driving mechanism moves the upper clamp 3 up and down through the transmission rod 23, so that the bearing 16 is pressed into the shaft 15, and the upper clamp 3 and the lower clamp 2 are respectively connected with The vacuum generator is connected, and the vacuum gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com