Barrel washing machine

A drum washing machine, drum technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of increasing the transportation cost and repair time of washing machines, the difficulty of replacing small parts, and the decline in the reliability of consumer products, etc. , to achieve the effect of reducing maintenance costs, reducing maintenance time, and preventing back and forth/left and right shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

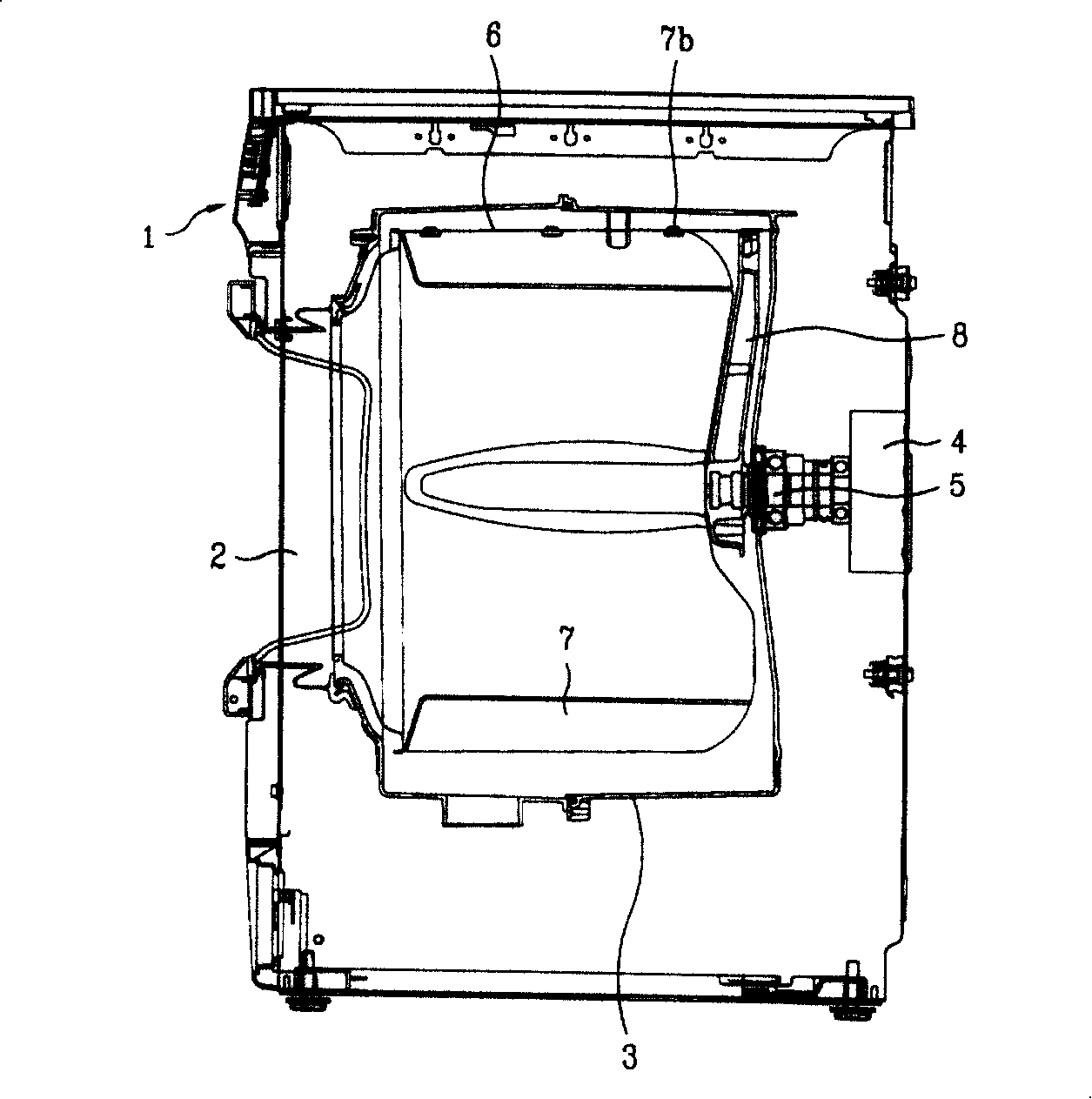

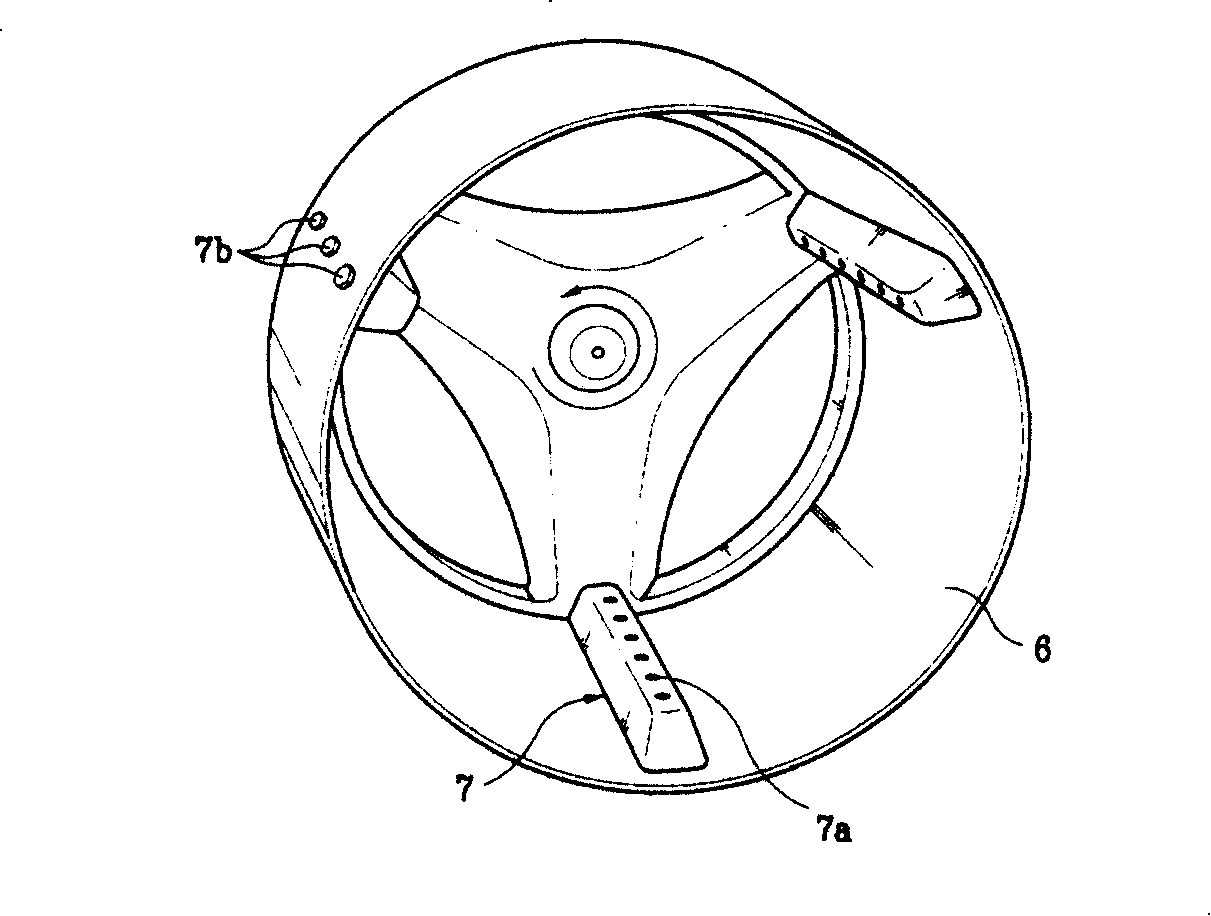

[0043] Such as Figure 4 As shown, the drum type washing machine of the present invention includes a drum 6 and at least one lifting arm 100 , and the lifting arm 100 includes: a cover portion 120 , a bottom portion 101 and a support portion 130 .

[0044] The drum 6 is arranged inside the washing tub to be rotatable, and the lifting arms 100 are arranged on the inner surface of the drum at regular intervals along the circumferential direction of the drum 6 .

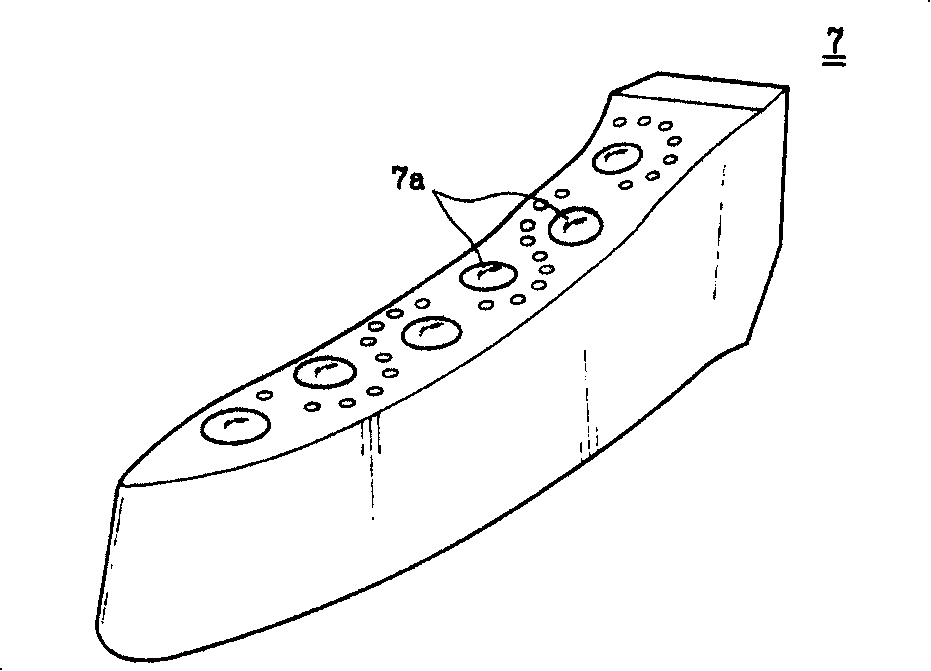

[0045] The lifting arm 100 has the function of lifting the laundry and making it drop when the drum rotates, and at least one protruding washing ball is arranged on the lifting arm 100 . When in contact with the laundry, the washing ball rotates gently to avoid damage to the laundry. The washing ball 103 adopts a ceramic material that can rotate when rubbing against the laundry.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com