Railway large-bore tunnel oval-shaped table-board cap brim bias-cutting type hole-door construction method

A construction method and large-section technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of large number of construction joints, large structural size deviation, complex formwork installation, etc., to achieve less construction joints and small structural size deviation , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

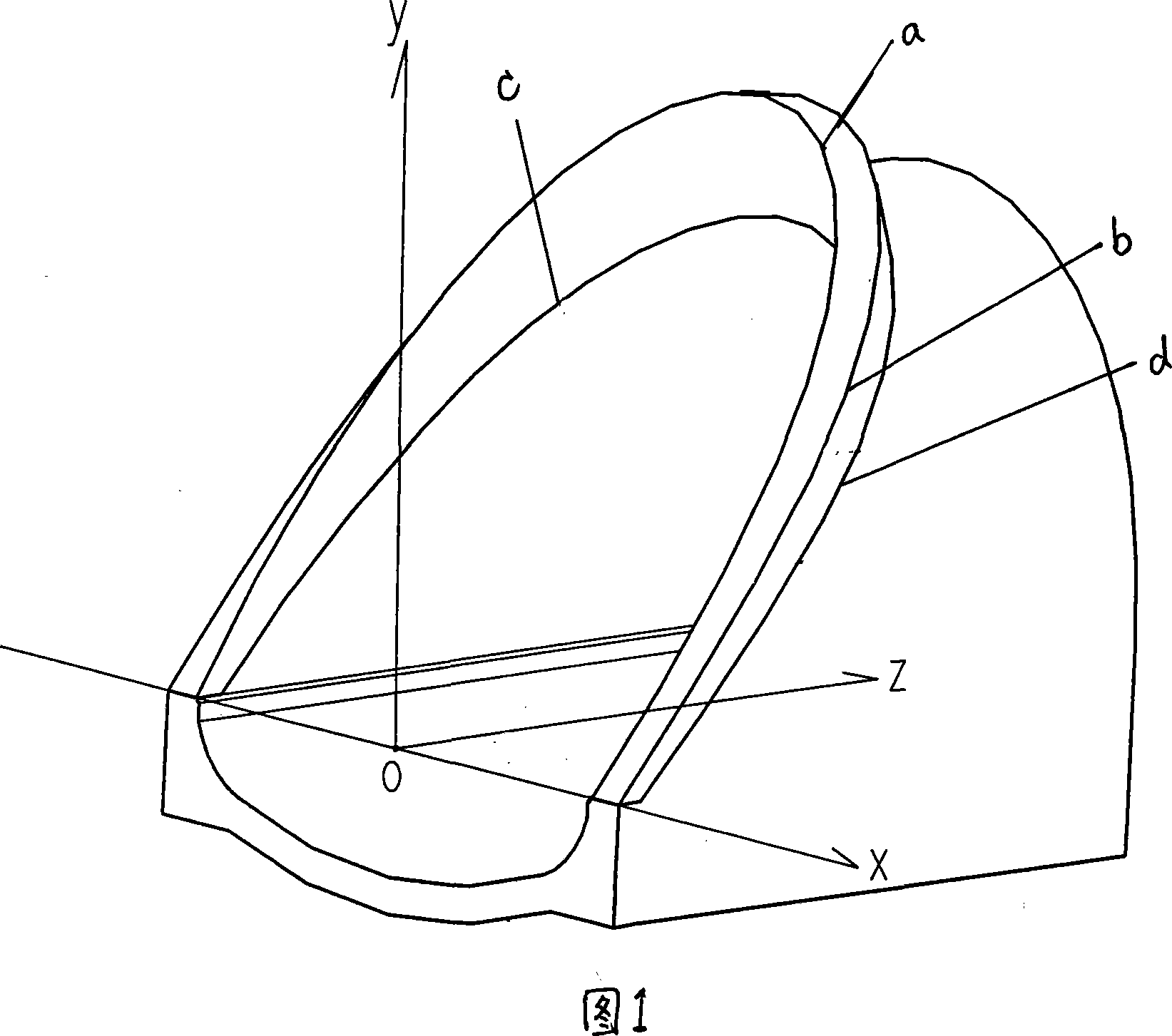

[0015] A method for constructing a large-section railway tunnel with an elliptical platform hat brim obliquely cut type portal, comprising open hole construction, oblique section construction and hat brim construction, the hat brim construction comprising the following steps: (1) making the inner hat brim according to the size and shape of the tunnel section The templates of the contour surface, the outer contour surface and the top surface, that is, the inner mold, the outer mold and the end mold, as shown in Figure 1, the inner mold is composed of elliptical contour lines a and c, and the outer mold is composed of elliptical contour lines b and d. The bottom surface of the hat brim is the oblique surface that has been applied. The hat brim entity is an ellipse platform composed of four elliptic curves. The inner contour surface, outer contour surface, bottom surface and top surface of the hat brim are all curved surfaces. Two elliptic curves and their relative positions are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com