Inner rail gauge for scribing large diameter circular arc

A large-diameter, arc-shaped technology, applied in the field of scribing tools, can solve the problems of non-reusable, low scribing accuracy, and inconvenient operation, and achieves the effect of high arc scribing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present invention will be described in detail below with a scribing and positioning tool with a large-diameter arc of a specific structure. Its structure is as follows:

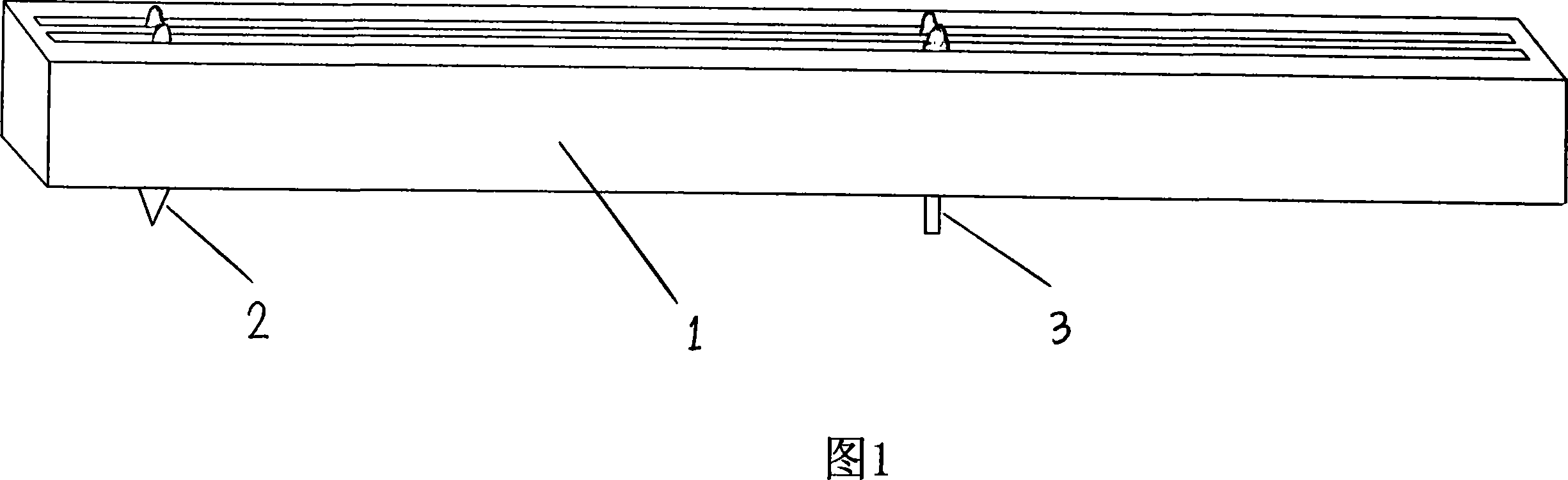

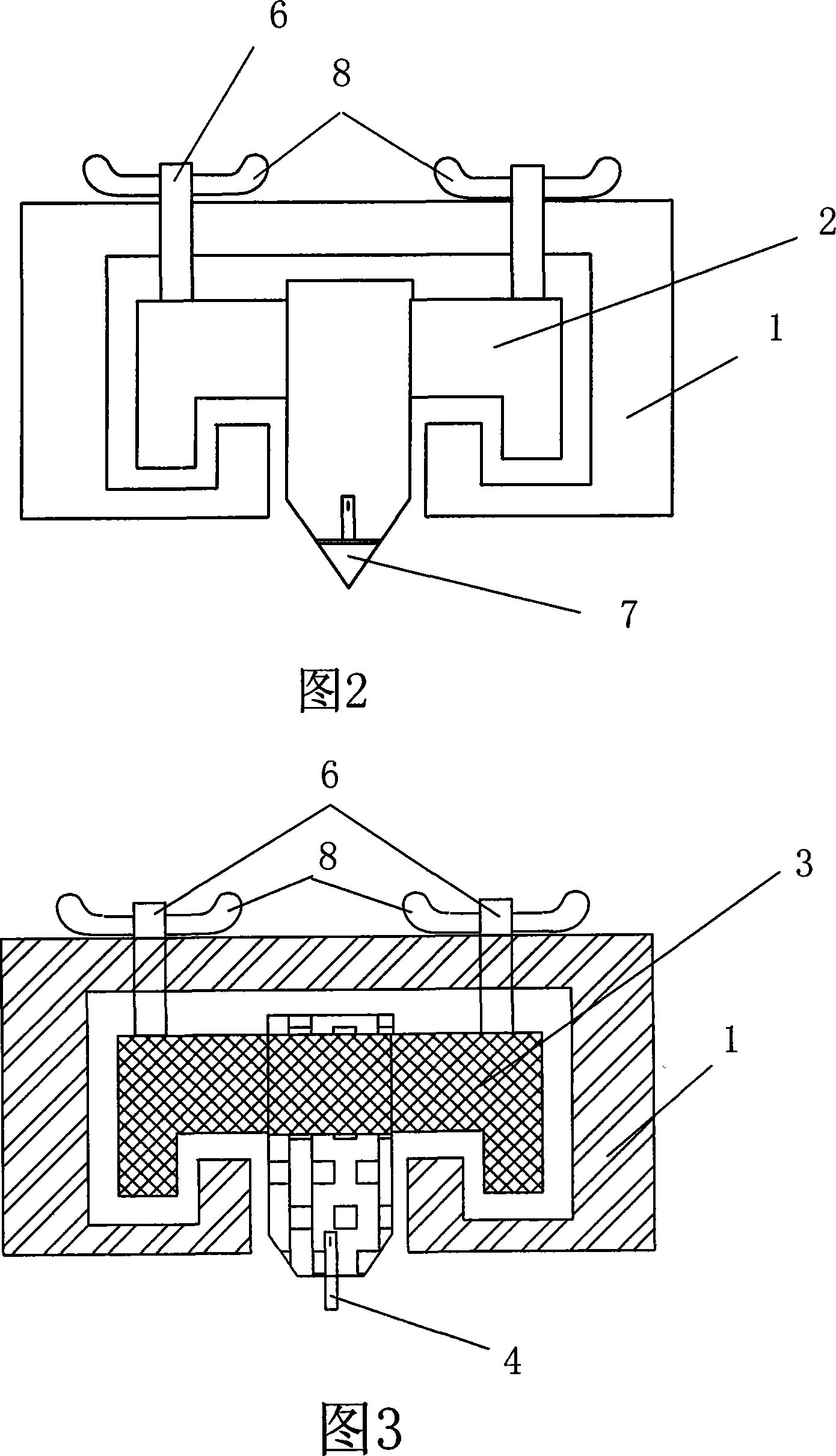

[0034] The inner rail gauge with a large diameter arc, its main structure mainly includes a linear gauge rod 1, a circle center slider 2 embedded in the inner groove of the gauge rod 1, and a center slider embedded in the inner groove of the gauge rod 1 The dash slider in 3. The profile of the center slider 2 and the marking slider 3 is similar to the profile of the inner groove of the gauge rod 1 and slightly smaller than the inner edge of the inner groove, so the two sliders can be embedded in the Slip back and forth in the longitudinal position in the inner groove of the gauge rod 1, but basically it will not affect its transverse position. The inner groove of the gauge rod 1 is larger than the outer contour of the two sliders, so that it can slide arbitrarily in the inner groove, that is, the...

Embodiment 2

[0040] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is:

[0041] First, the scale is engraved on one side of the upper through groove of the gauge bar 1, and the centers of the wing nuts 8 of the circle center slider 2 and the marking slider 3 are respectively set to indicate their positions. Guided by the red line, the precise position of the circle center slider 2 or the marking slider 3 can be known, and then the distance between the two can be accurately determined to realize the precise setting of the radius of the drawn arc.

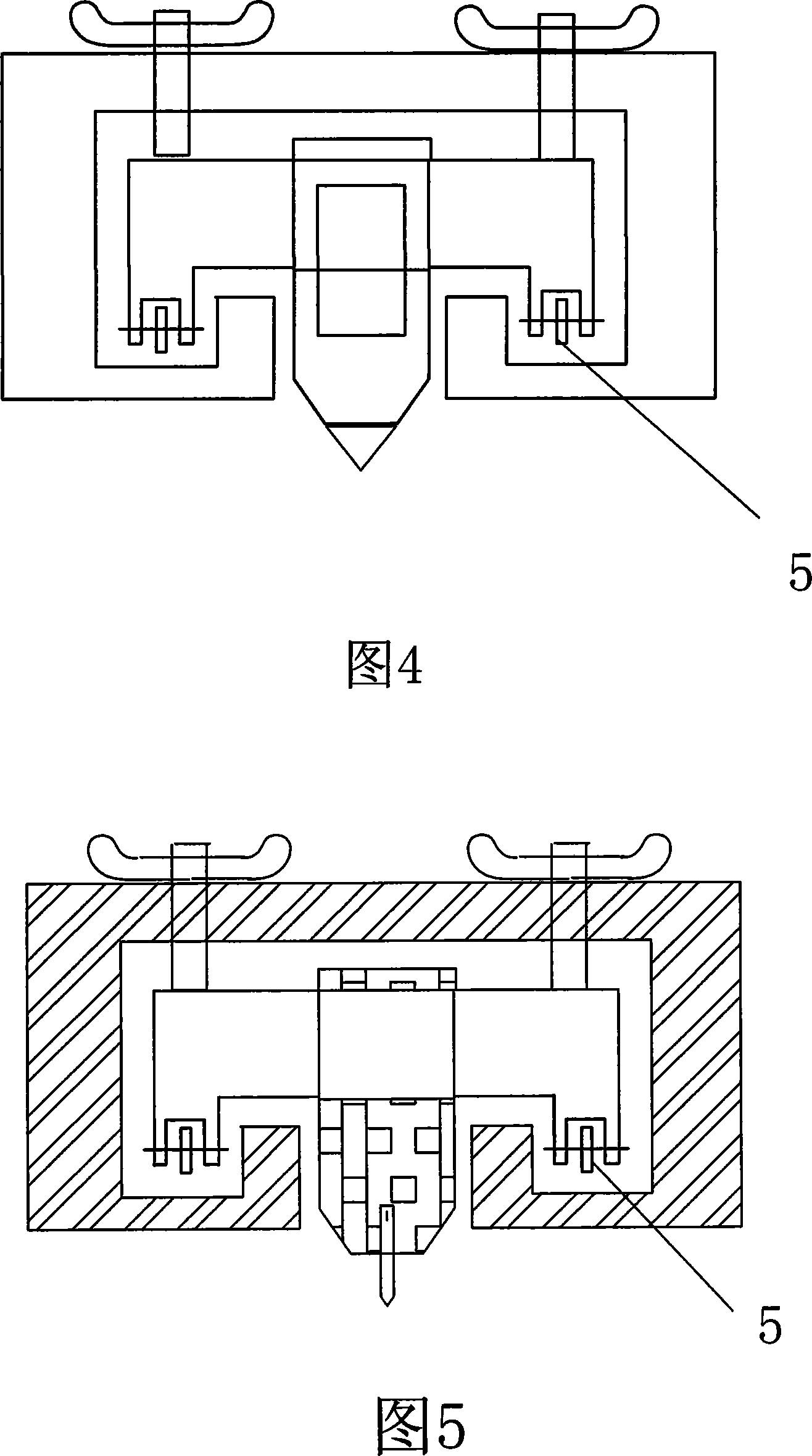

[0042] Second, two pulleys 5 are respectively arranged opposite to the locking bolt 6 on the center of circle slider 2 and the marking slider 3, and two pulleys 5 are respectively provided on both sides of the positioning pin 7, and the both sides of the marking device 4 are also provided with two pulleys 5. Two pulleys 5 are respectively established. In this way, there are four pulleys under each sli...

Embodiment 3

[0044] Embodiment 3 is basically the same structure as Embodiment 2, the difference is:

[0045] A side channel is formed on the side wall of the gauge rod 1, and scales are arranged on both sides of the side channel. Simultaneously, a vertical red line is respectively set on the sides of the center of circle slider 2 and the marking slider 3, and the position of each slider and the distance between the two are precisely determined by the side channel and the red line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com