Self-discharging semitrailer vehicle frame

A semi-trailer and frame technology, which is applied to vehicle components, tilt-bearing vehicles, and substructures, etc., can solve the problems of trailers easily overturned, high center of gravity of goods, accidents, etc., so as to improve transportation efficiency, reduce the height of the center of gravity, increase the large volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

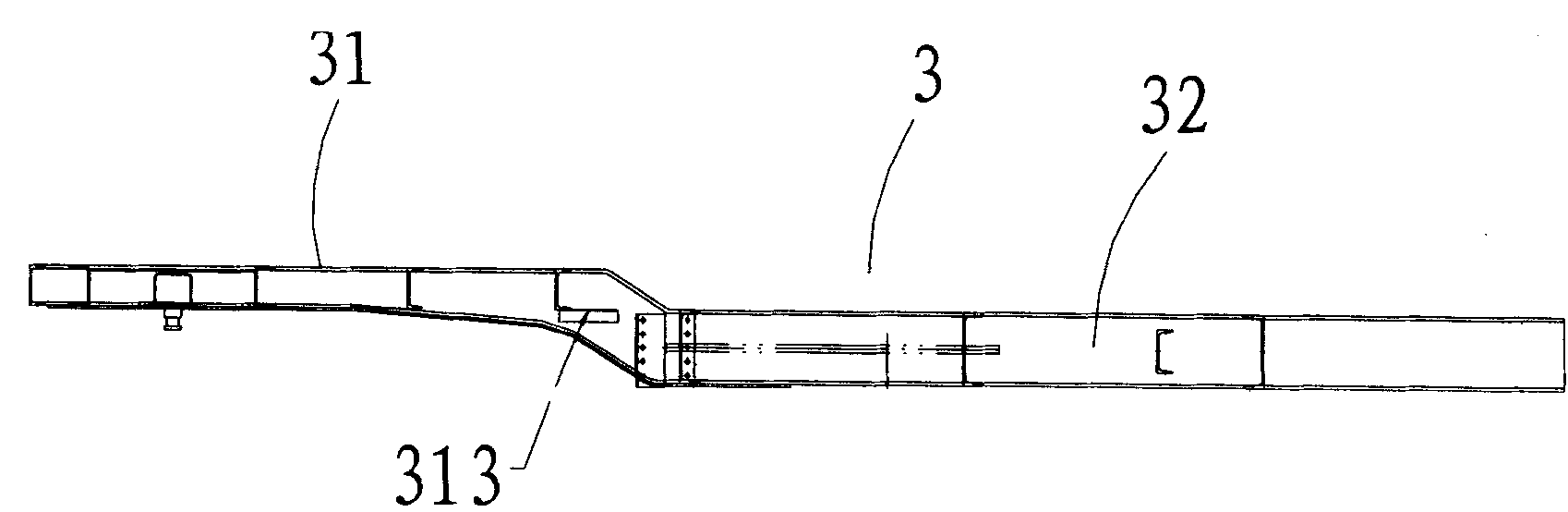

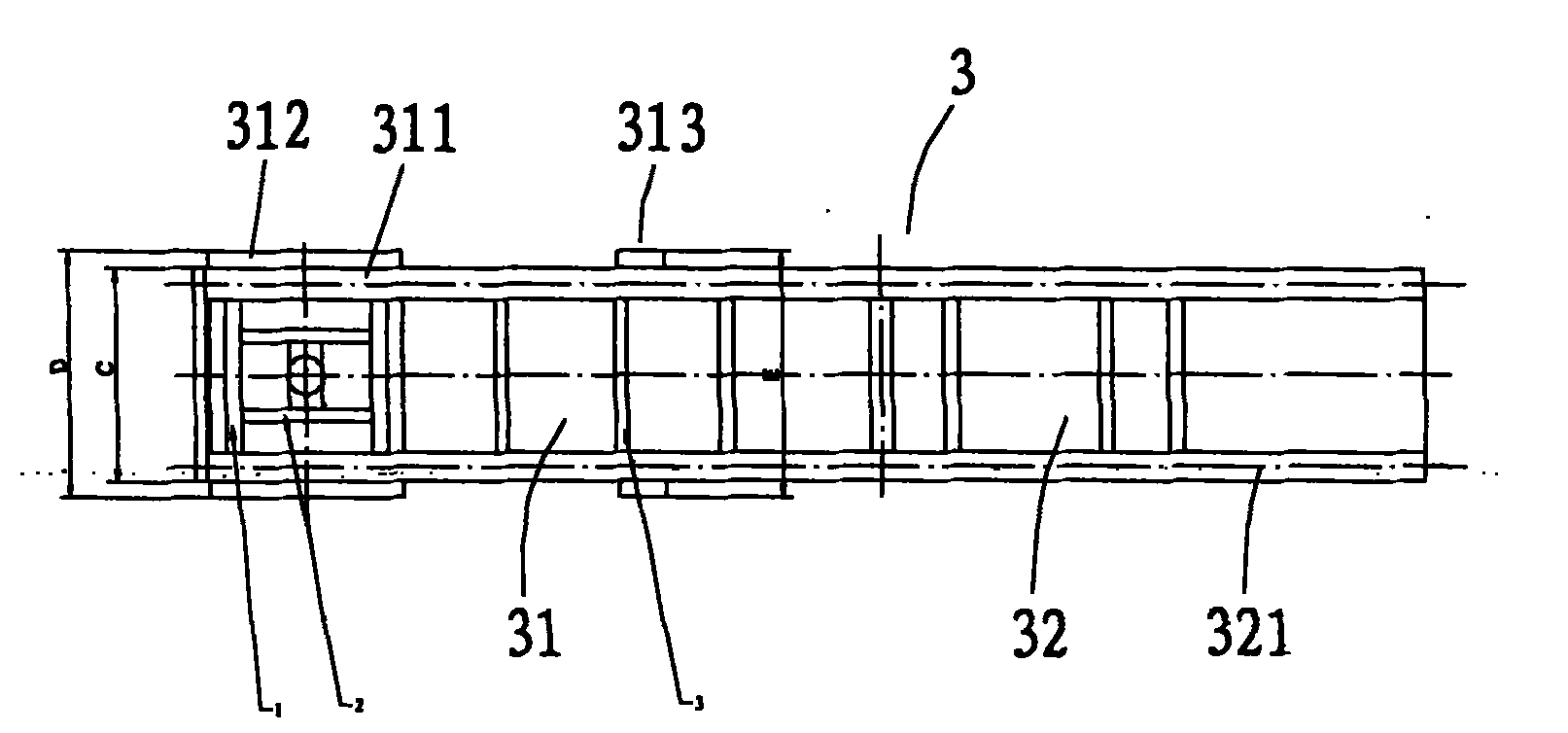

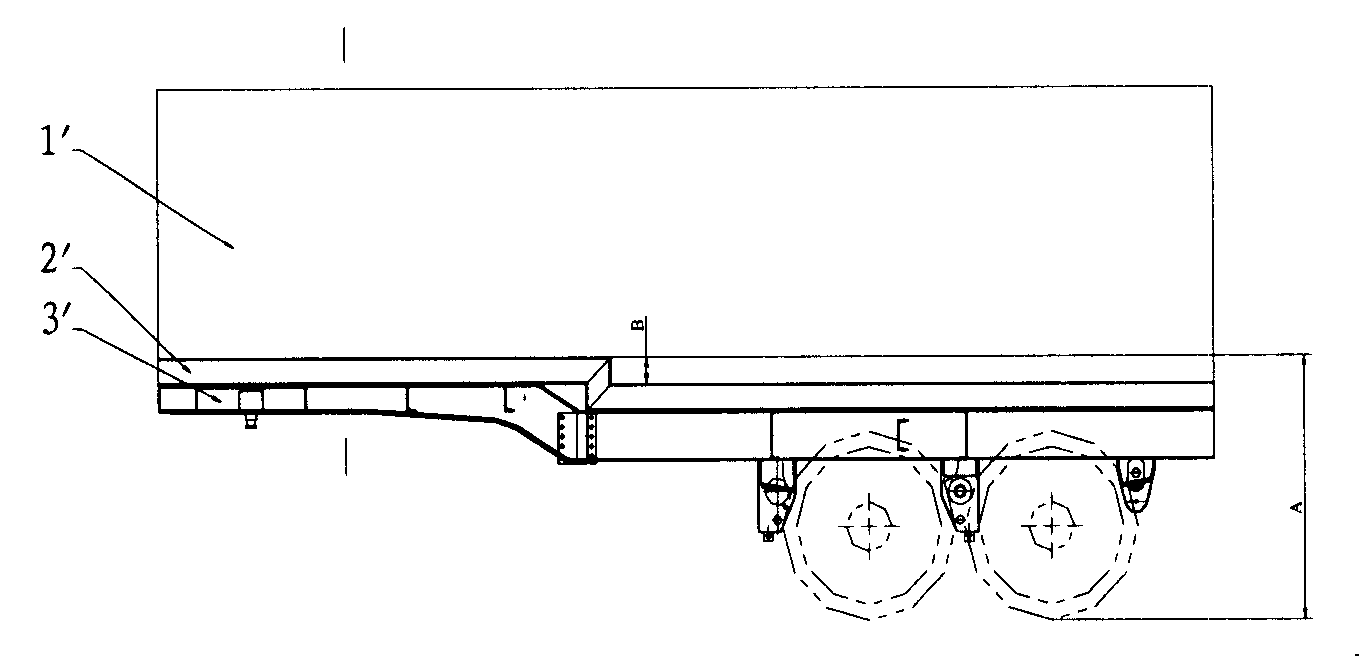

[0046] The self-unloading semi-trailer vehicle frame of the present invention as shown in Figure 2 comprises upper frame 2 and lower frame 3, and the concrete structure of upper frame 2, lower frame 3 is as follows:

[0047] Shelves 2

[0048] Such as Figure 3A , 3B As shown, the upper frame 2 is a load-bearing platform formed by connecting a plurality of transversely extending beams 34 with two longitudinally extending longitudinal beams and two side beams 25, and the upper frame is divided into a gooseneck part longitudinal beam 21 and a rear part longitudinal beam twenty two.

[0049] From Figure 3A , 3B It can also be seen in the figure that the setting of the front part of the longitudinal beam 21, the setting of the connecting cross brace 24, and the setting of the part of the longitudinal beam 22 after the putting on the shelf. details as follows:

[0050] 1. The setting of the longitudinal beam 21 of the upper gooseneck part: its internal width is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com