Vertical highway transport vehicle

A technology for transport vehicles and roads, which is applied in the direction of vehicles, etc. It can solve the problems that ordinary vehicles cannot meet the requirements of use and road transportation is difficult, and achieve the effect of meeting high stability, meeting load-bearing requirements, and reducing the quality of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment is illustrated by taking the satellite airtight container (with payload inside) for transporting the CZ-3B launch vehicle as an example. The airtight container has a maximum diameter of 4150 mm and a centroid height of 3100 mm.

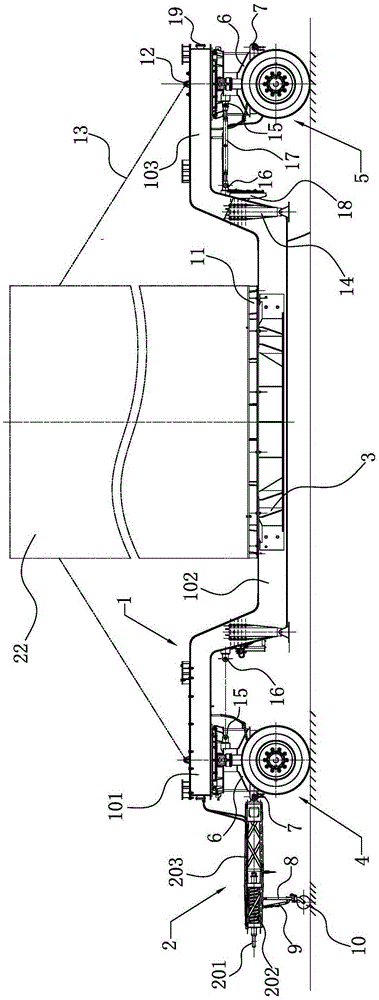

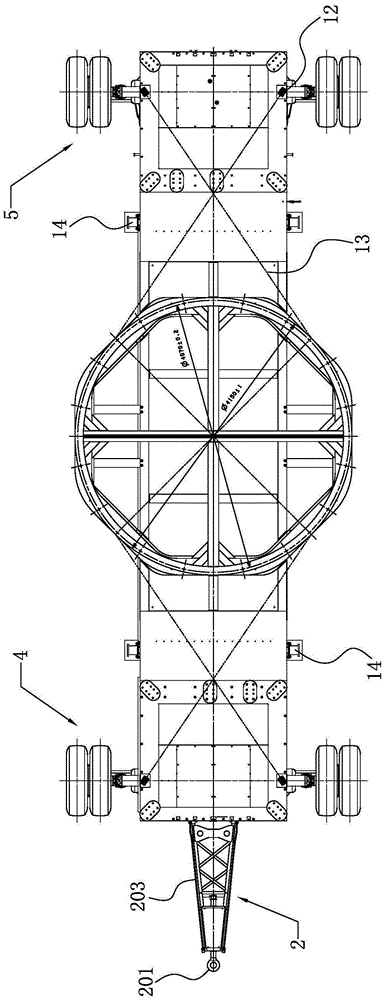

[0022] Such as figure 1 shown, combined with figure 2 As shown, the vertical road transport vehicle of the present invention includes a frame assembly 1 and a traction mechanism 2. The frame assembly 1 includes a frame body and a widened beam 3. The frame body includes front load-bearing surfaces that are sequentially fixed and connected. 101. The middle bearing surface 102 and the rear bearing surface 103. The height of the middle bearing surface 102 is lower than that of the front and rear bearing surfaces 101 and 103. Both sides are respectively provided with a widening beam 3, the front wheel set 4 is installed under the front bearing surface 101, the rear wheel set 5 is installed under the rear bearing surface 103, and th...

Embodiment 2

[0044] In this embodiment, the assembly of the CZ-3B carrier rocket is taken as an example for illustration. The maximum diameter of the assembly is 4200 mm, and the height of the center of mass is 2546 mm.

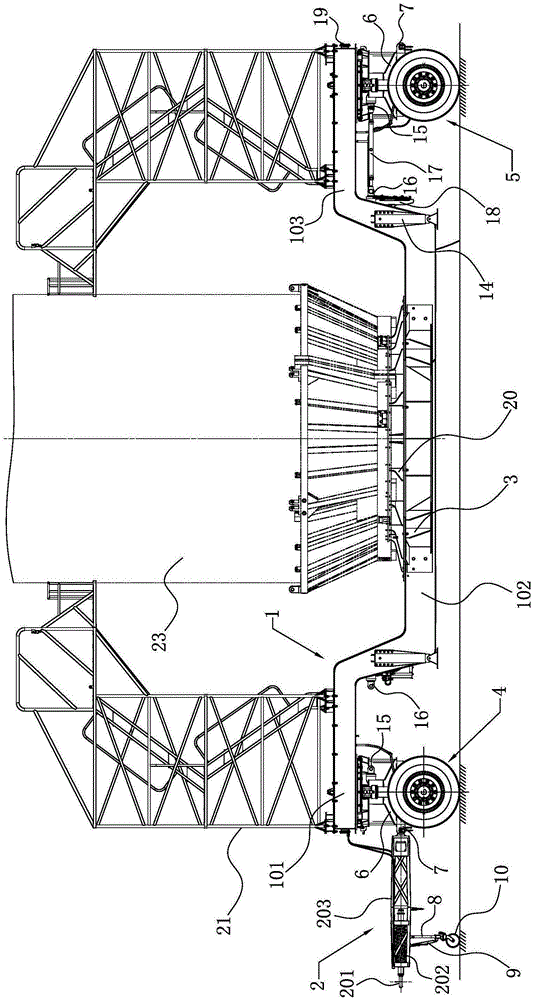

[0045] Such as image 3 shown, combined with Figure 4 As shown, the vertical road transport vehicle of the present invention includes a frame assembly 1 and a traction mechanism 2. The frame assembly 1 includes a frame body and a widened beam 3. The frame body includes front load-bearing surfaces that are sequentially fixed and connected. 101. The middle bearing surface 102 and the rear bearing surface 103. The height of the middle bearing surface 102 is lower than that of the front and rear bearing surfaces 101 and 103. Both sides are respectively provided with a widening beam 3, the front wheel set 4 is installed under the front bearing surface 101, the rear wheel set 5 is installed under the rear bearing surface 103, and the front and rear wheel sets 4, 5 pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com