Materials allocating, storing and outputting equipment

A technology for outputting equipment and materials, applied in storage devices, conveyor objects, transportation and packaging, etc., can solve problems such as material back-blocking, poor processing speed, and limited material storage and output equipment configuration quantity and working space, etc. Achieve the effect of increasing speed and saving configuration space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

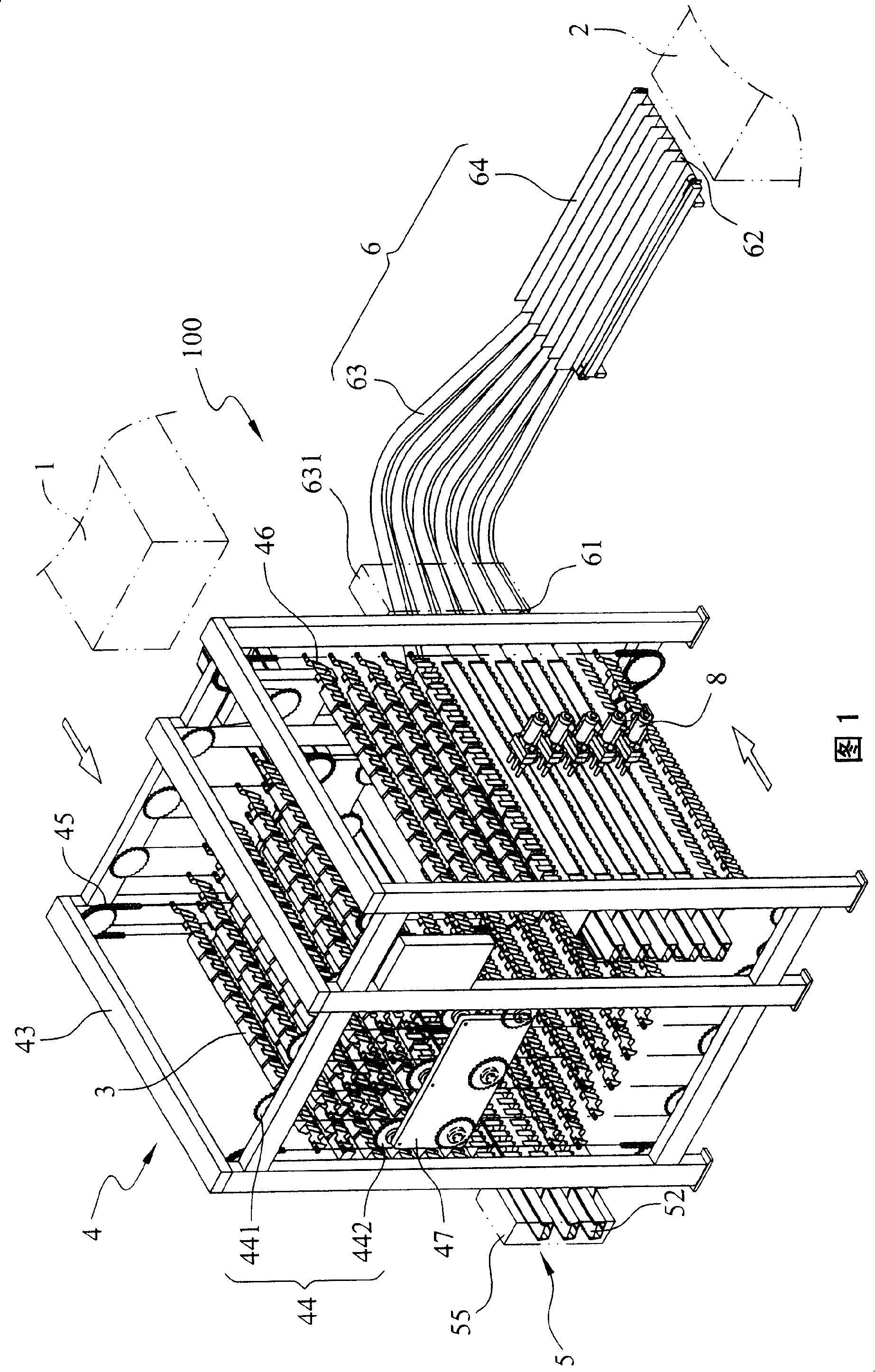

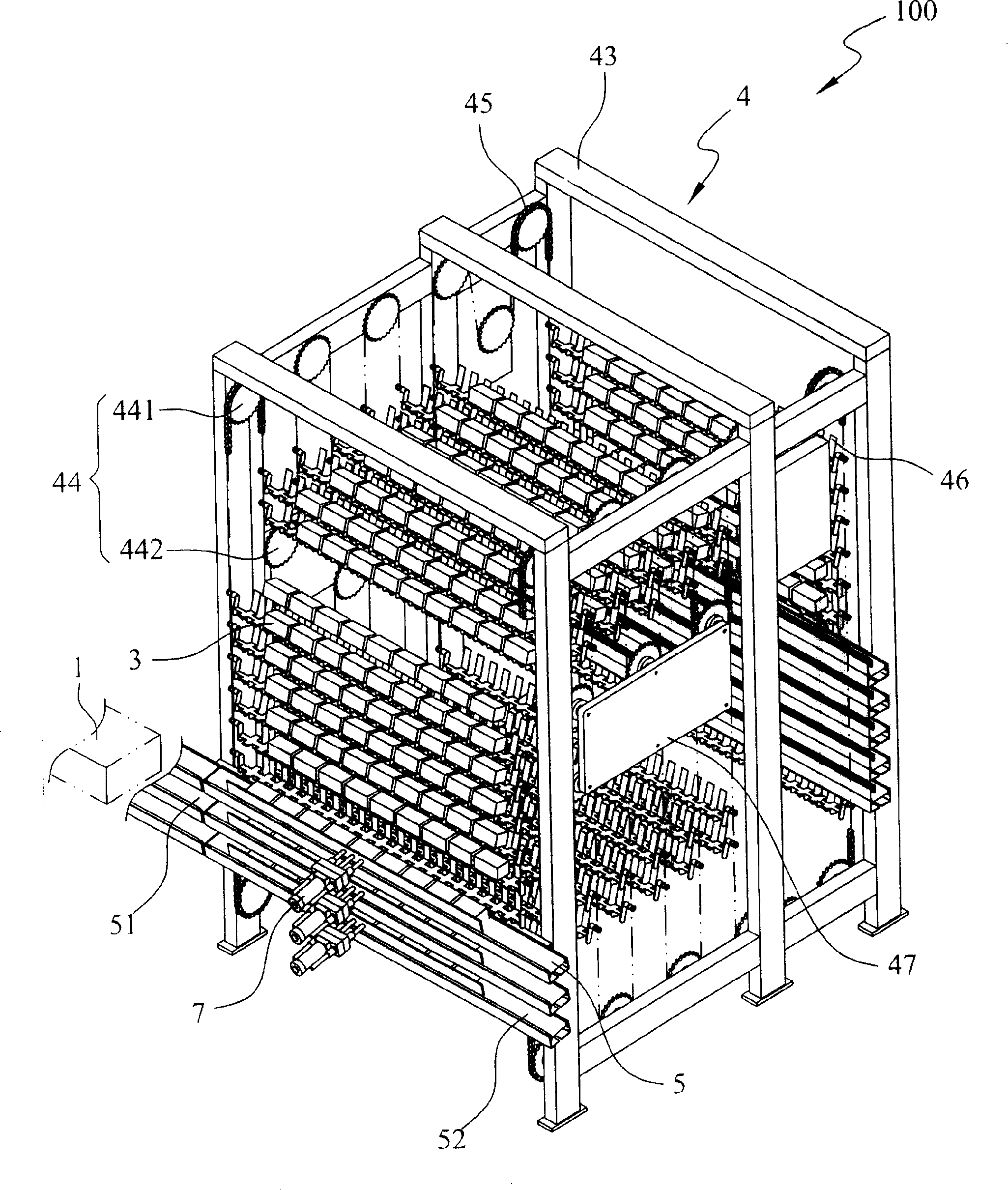

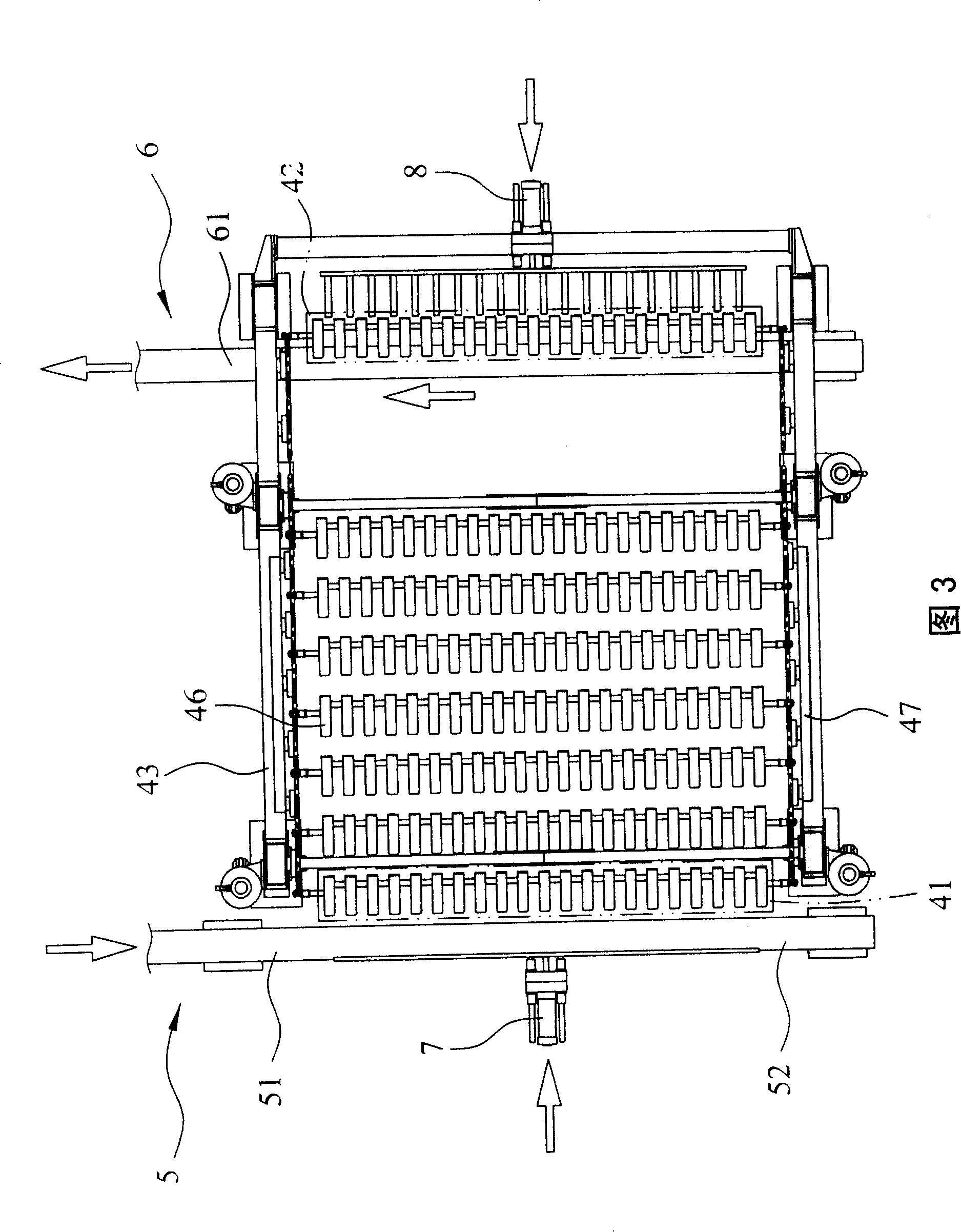

[0057] Refer to Figure 1 to Figure 4 , Figure 1 is a first perspective view of a preferred embodiment of the present invention, figure 2 Is a second perspective schematic view of the preferred embodiment of the present invention, and FIG. 3 is a schematic top view showing the preferred embodiment of the present invention, Figure 4 It is a schematic diagram showing the movement lines of storing and outputting materials in a preferred embodiment of the present invention. As shown in the figure, a material allocation storage and output device 100 is configured between a material input area 1 and a material output area 2, and multiple materials 3 are allocated and stored from a material input area 1 according to the work capacity , And then deploy and output to a material output area 2.

[0058] The capacity deployment storage device 100 includes a capacity deployment storage device 4, a plurality of feeding conveying channels 5, a plurality of discharging conveying channels 6, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com