Fuel filter unit for diesel internal combustion engines

A diesel internal combustion engine and filter technology, which is applied to engine components, machines/engines, liquid fuel feeders, etc., can solve the problems of increasing the overall size of the filter unit, large cost, and expensive components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

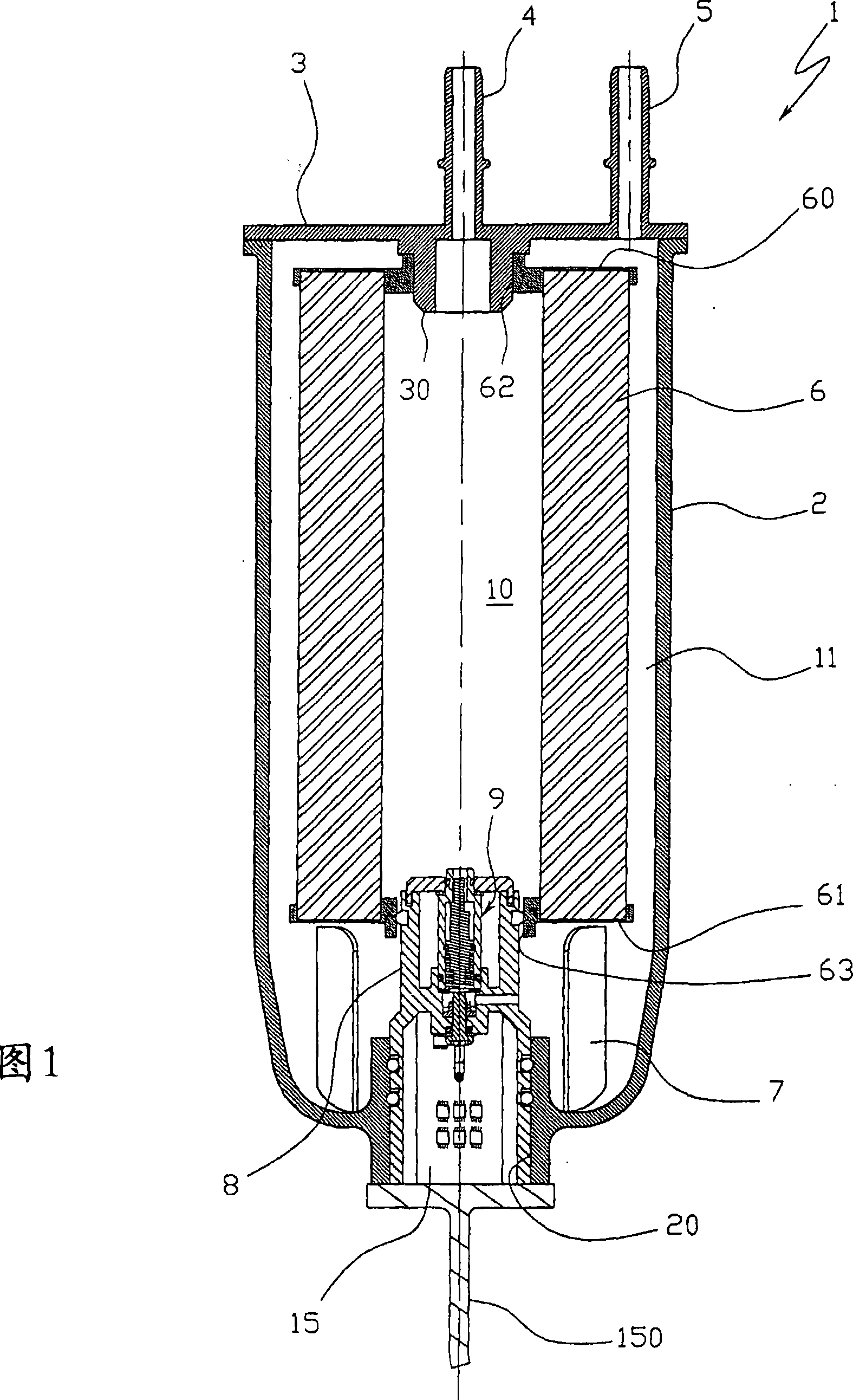

[0016] Said FIG. 1 shows a filter unit 1 comprising a cup-shaped housing 2 closed at the top by a cover 3 on which a fuel inlet pipe 4 and a fuel outlet pipe 5 are arranged.

[0017] The interior of the housing 2 houses an annular filter baffle comprising an upper end 60 and a lower end 61 having a central hole indicated by reference numerals 62 and 63 respectively.

[0018] The central hole 62 of the upper end 60 accommodates the rod 30 extending downwardly from the cover 3 at the pipe 4; Angular equidistant fins 7 branched from the lower surface.

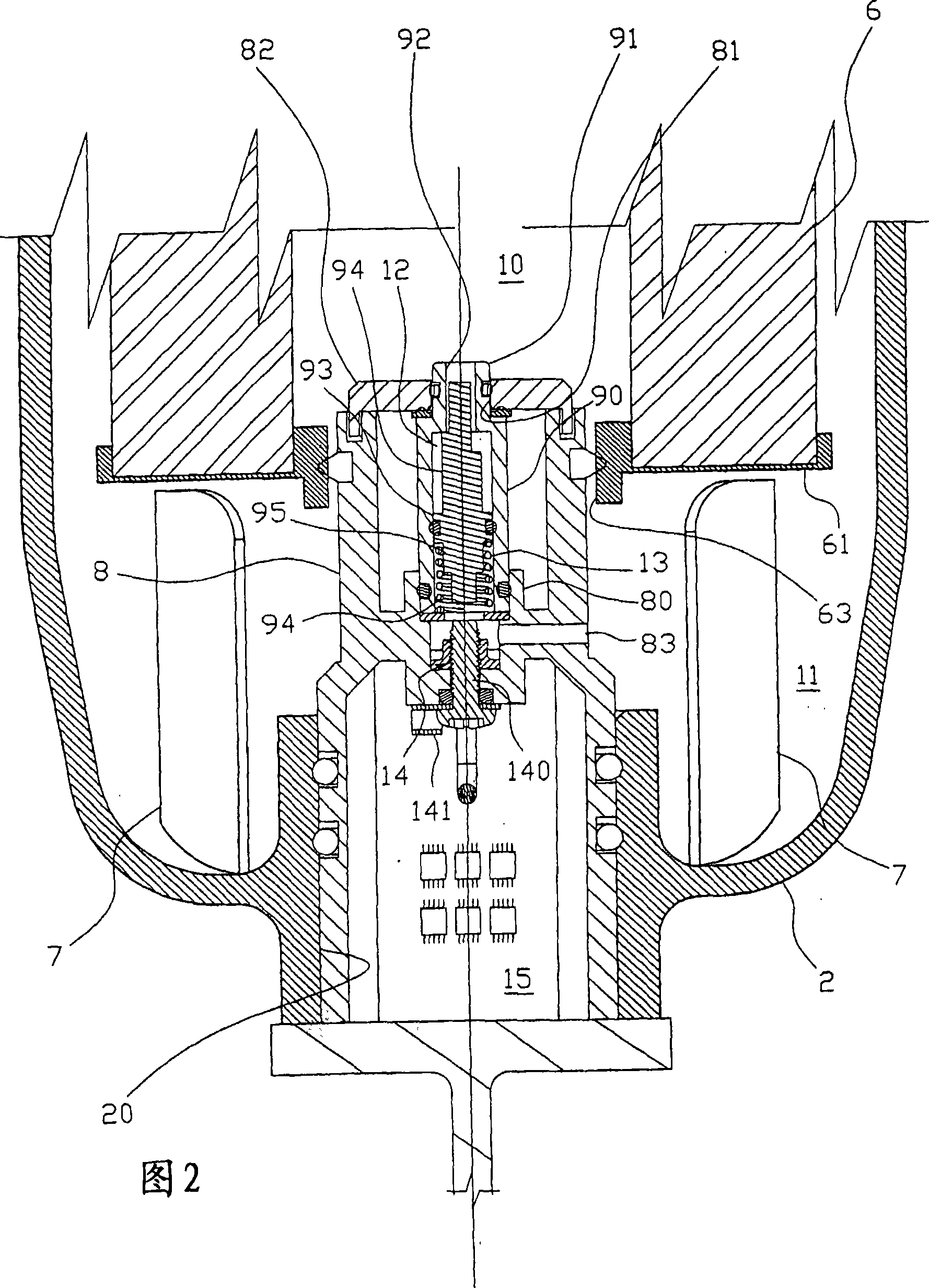

[0019] Said housing 2 is provided in the lower part with a tubular hole 20 accommodating a bracket 8 inserted into a hole 63 extending inside the filter baffle.

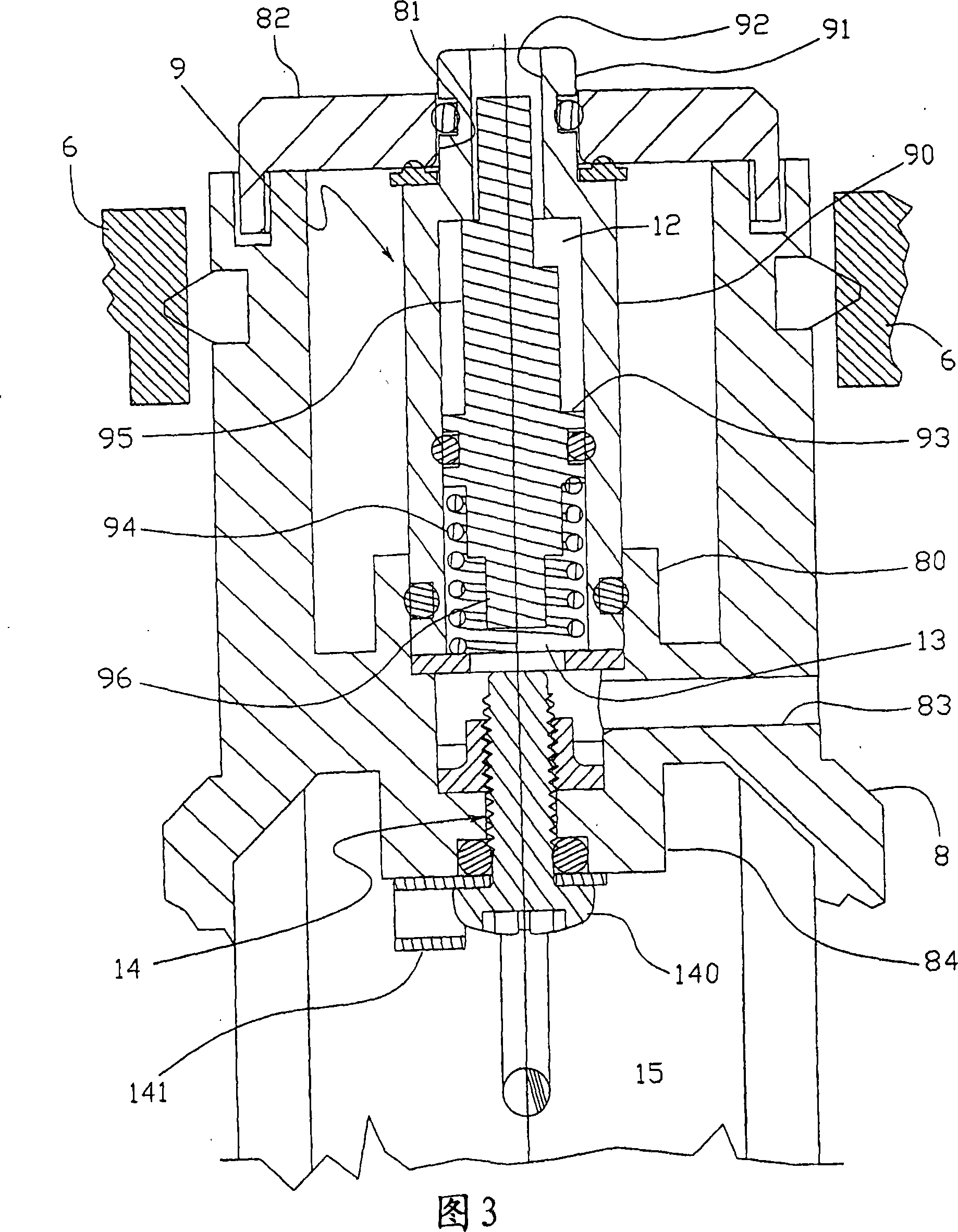

[0020] Said support 8 carries, close to the hole 63 , means 9 for determining a clogging of the filter baffle 6 .

[0021] The filter baffle 6 and device 9 roughly divide the interior of the housing 2 into two independent chambers 10 and 11, wherein the first chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com