Solidified holding tray capable of controlling bonding excursion of center hole of double-layer optical disk

A center hole and tray technology, which is applied in the field of curing trays, can solve the problems of reducing the quality of discs and offset errors, and achieve the effect of ensuring production efficiency and eliminating offset errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

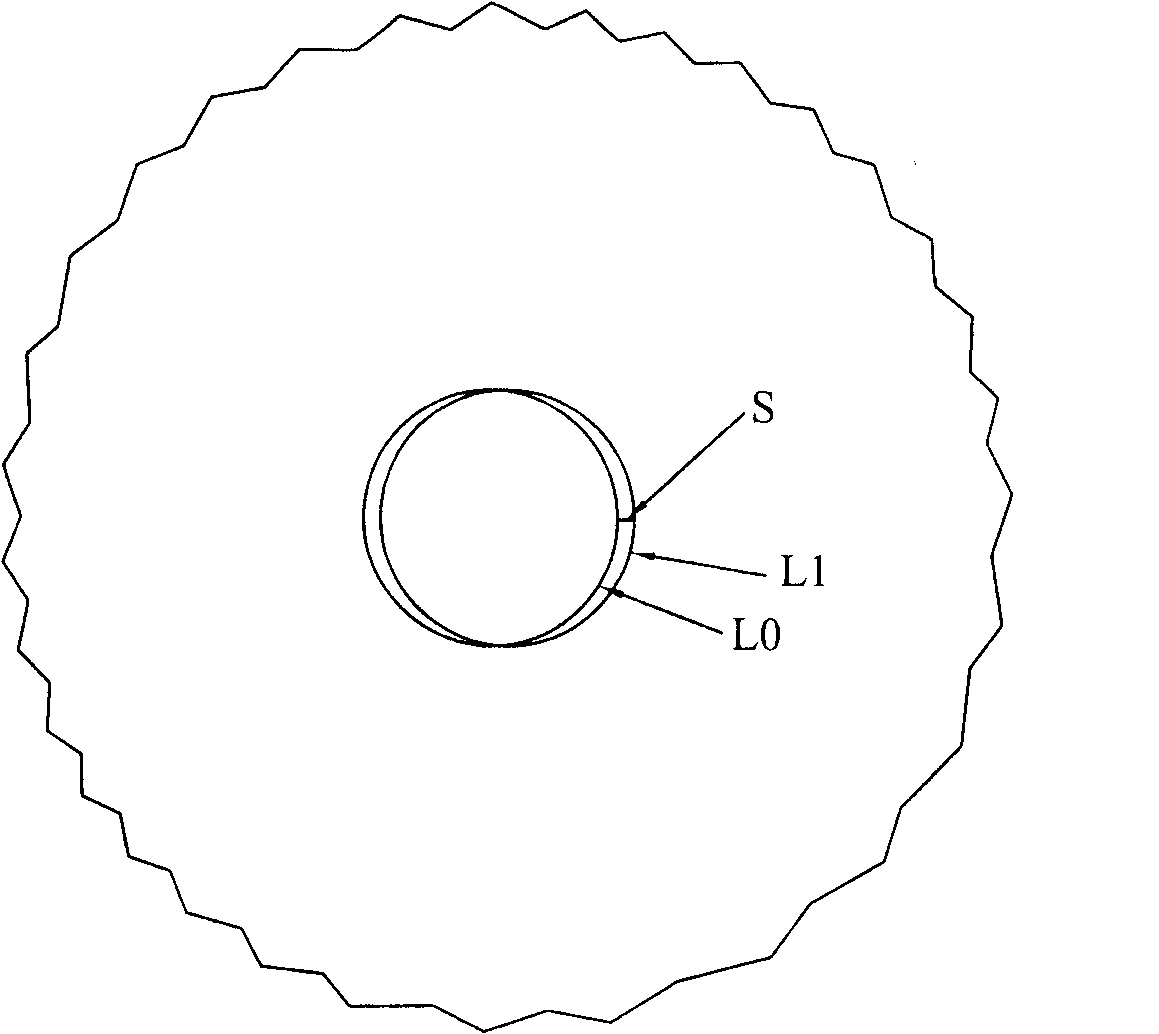

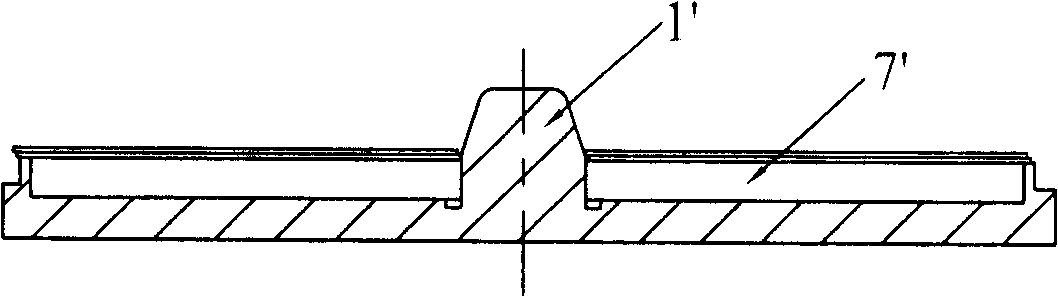

[0030] See figure 1 , which schematically shows the L0 layer and the L1 layer of the disc, where S represents the offset of the center hole of the DVD dual-layer disc. figure 2 The structure of the existing curing tray is shown, which includes a shaft core 1' and a carrier plate 7' for carrying an optical disc. The outer diameter of the shaft core 1' is φ14.8mm, and the inner diameter of the central holes of the two monoliths is φ15mm, so the fit between them is clearance fit. In this way, the central holes of the two single pieces will produce offset errors during the bonding process, thereby producing disk eccentricity (ECC).

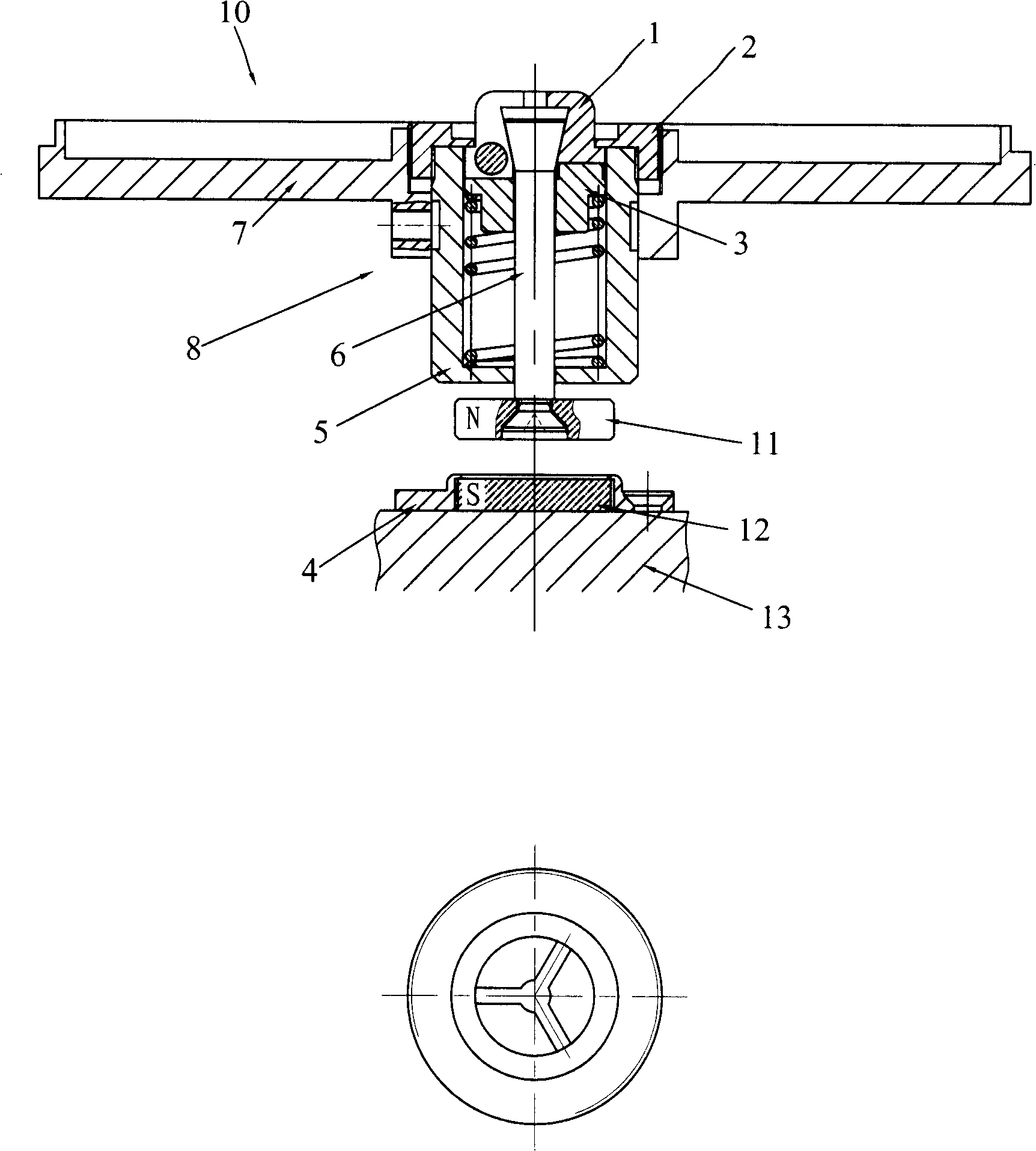

[0031] image 3 A structural sectional view and a partial (deflection control device) top view of the curing tray 10 of the present invention are shown. The curing tray 10 of the present invention is arranged on the curing turntable 9 in the curing device, and the curing turntable 9 is rotatably arranged above the substrate 13 of the optical disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com