Mixed mode shape memory alloy frictional damper

A technology of friction damper and memory alloy, which is applied to building components, shockproof, etc., can solve the problems of low energy consumption, residual displacement of friction damper, etc., and achieve the effect of enhancing survivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

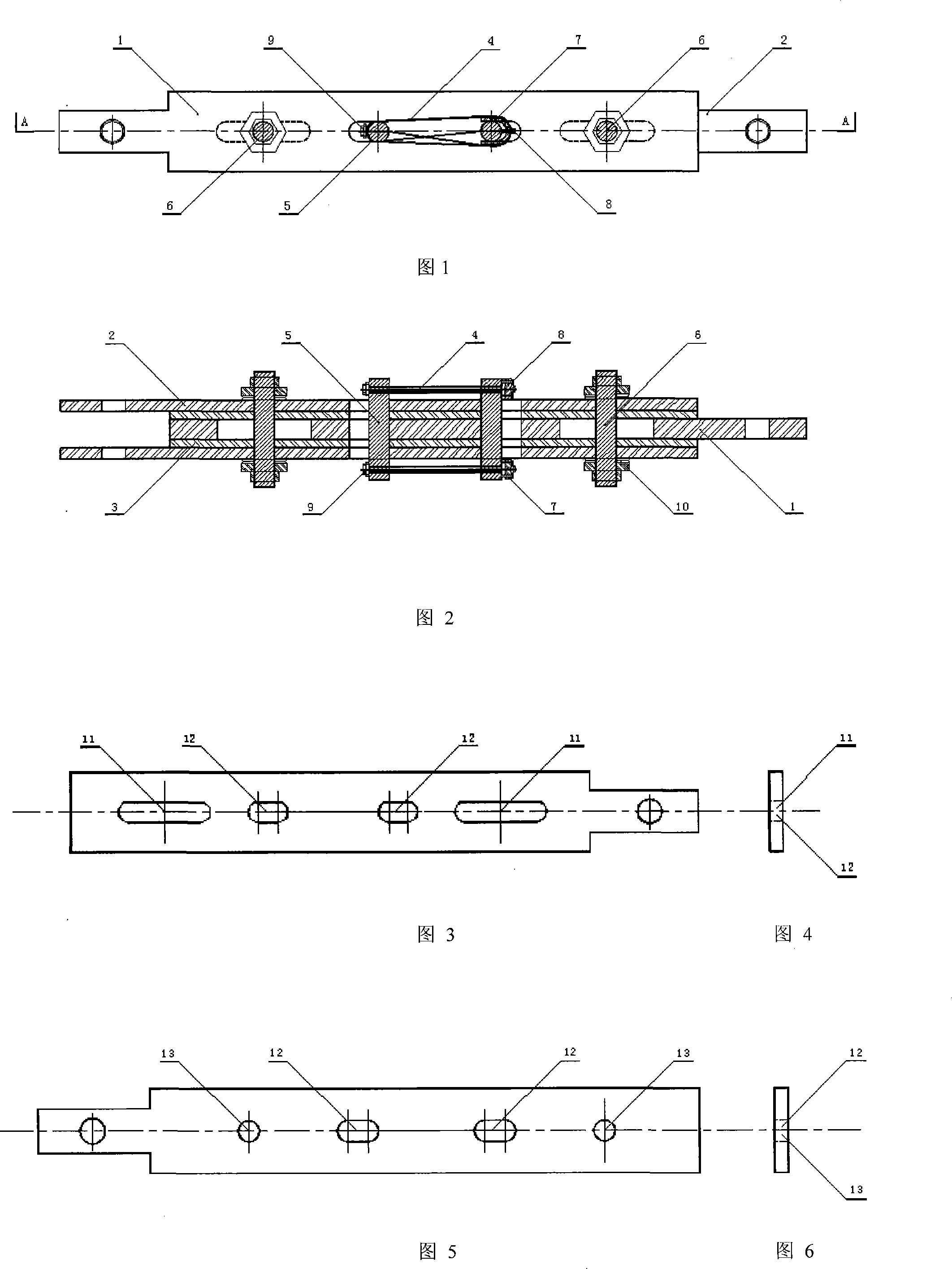

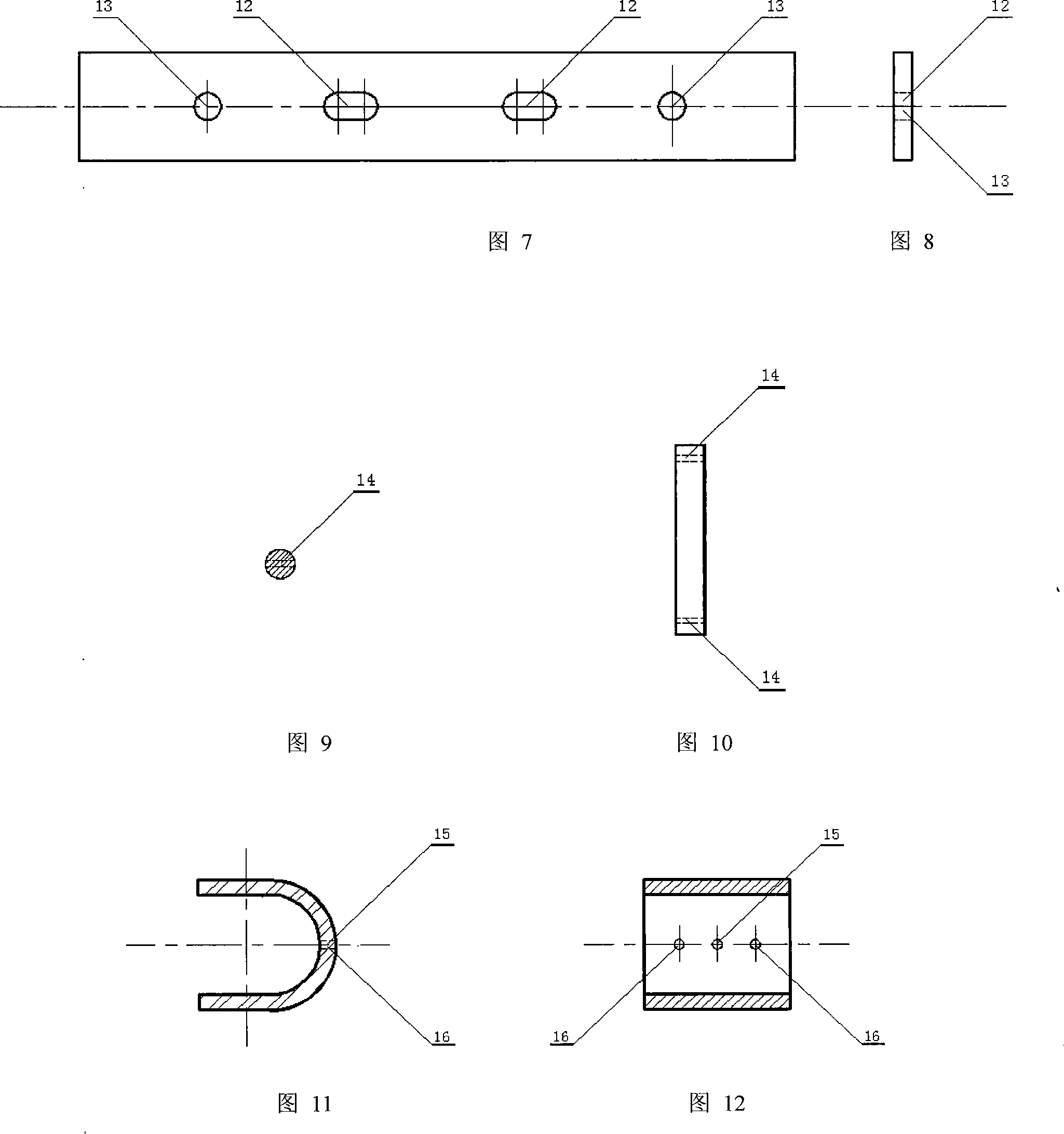

[0026] The implementation steps of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0027] (1) Under the action of small and large earthquakes, analyze the engineering structure, and determine the size and parameters of the damper according to the performance requirements to be achieved.

[0028] (2) Main board 1, auxiliary board 2, friction plate 3, superelastic shape memory alloy wire 4, reset rod 5, high-strength bolt 6, U-shaped pre-strain adjustment plate 7, adjustment screw 8, clamp 9 required for processing or purchasing and gasket 10.

[0029] (3) Adhere the secondary plate 2 and the friction plate 3 with industrial glue, and then assemble them with the main plate 1 through high-strength bolts 6 . When assembling, it is required that the active holes 12 of the tie rods on the main board 1, the sub-board 2 and the friction plate 3 are completely aligned. A washer 10 is added under the nut of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com