Screw for use in concrete

A screw and screw rod technology, applied in the direction of screws, nuts, bolts, etc., can solve the problems of increasing the number of threads, increasing the rotational resistance, and damage to concrete screws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following description, while different embodiments of the invention are shown and described, the same reference numerals are used for equivalent parts.

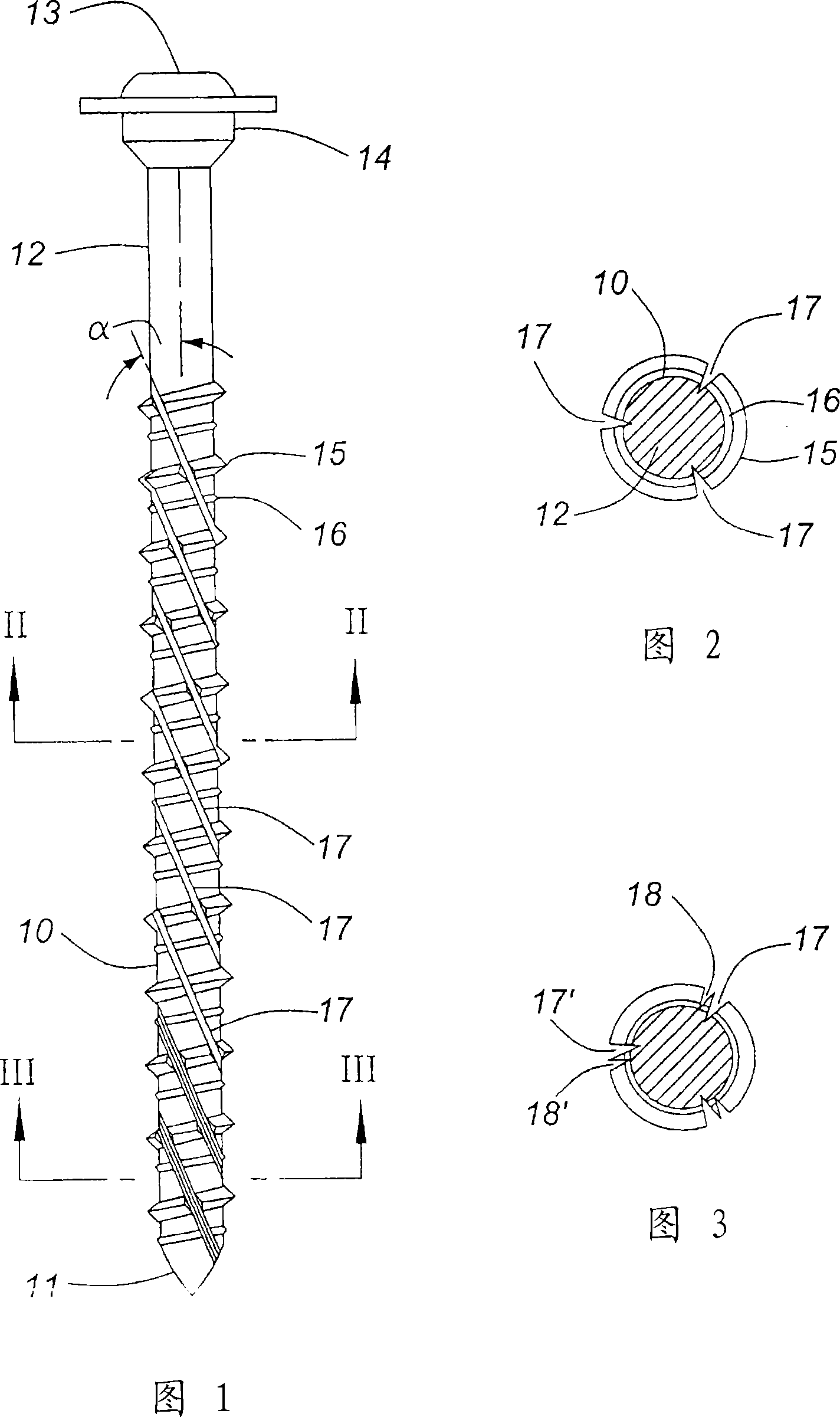

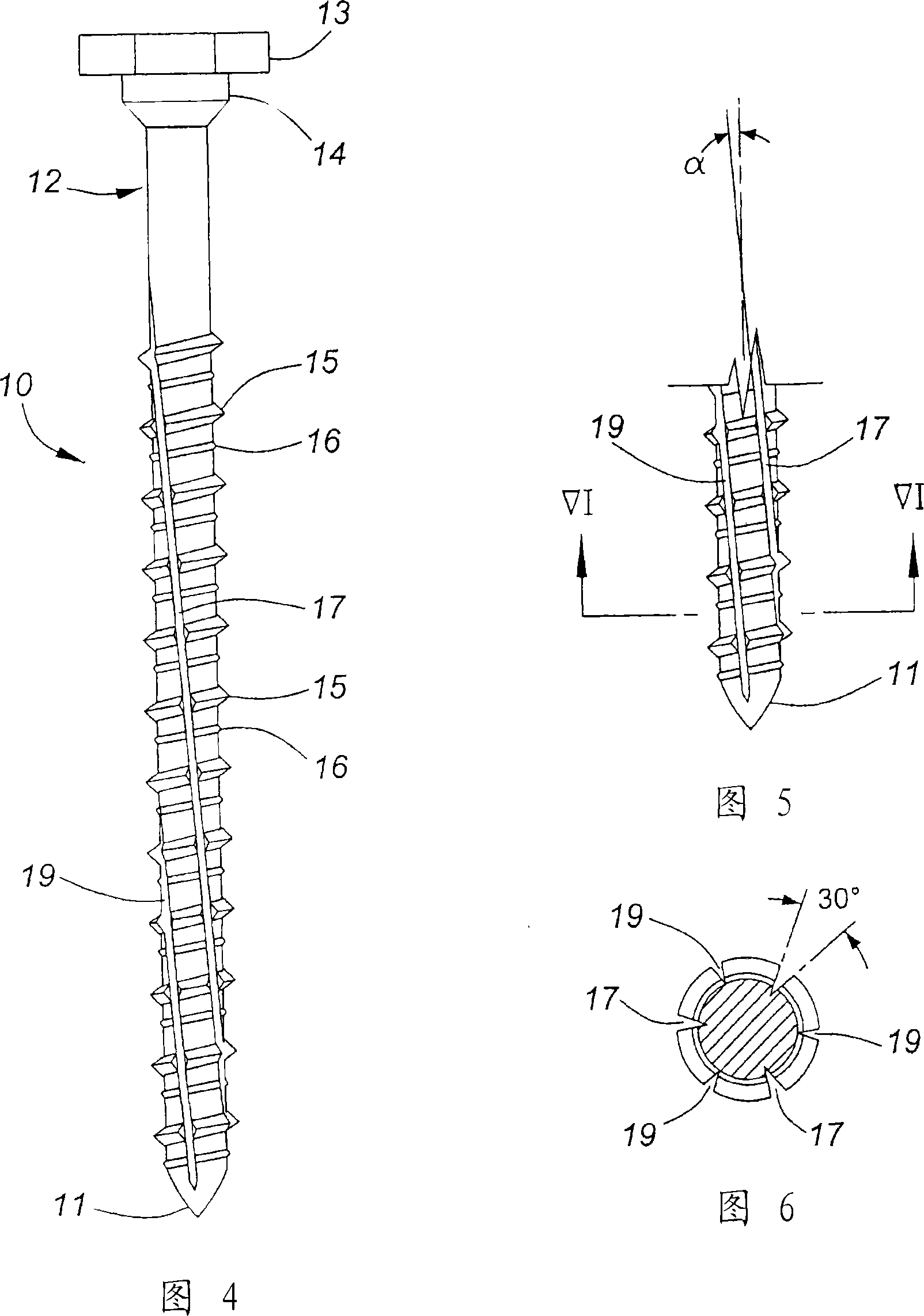

[0016] An exemplary concrete screw incorporating the present invention is shown in FIG. 1 . The screw is integrally formed, preferably from nickel, and comprises a screw shank 10 with a point 11 at one end. At the opposite second end of the screw shank 10 there is an unthreaded screw head end 12 . Preferably, the screw head end 12 has a slightly increased diameter to provide a smooth transition to the screw head 13 , for example by a truncated screw head conical transition 14 . The enlarged transition also enables larger or more powerful screw drivers to be accommodated.

[0017] Between the tip 11 and the screw head 12, the screw shaft 10 has at least two helical threads. The first thread 15 has a crest diameter (the diameter of a virtual cylinder enveloping the outer periphery of the thread) that is larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com