Fixing structure for slide way type cooker hood

A range hood and fixed structure technology, applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of excessive fixing, inconvenience, troubles, etc., and achieve improved firmness, good stability, and large force bearing surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the technical contents of the present invention more clearly, it is further described as follows in conjunction with preferred embodiments of the present invention:

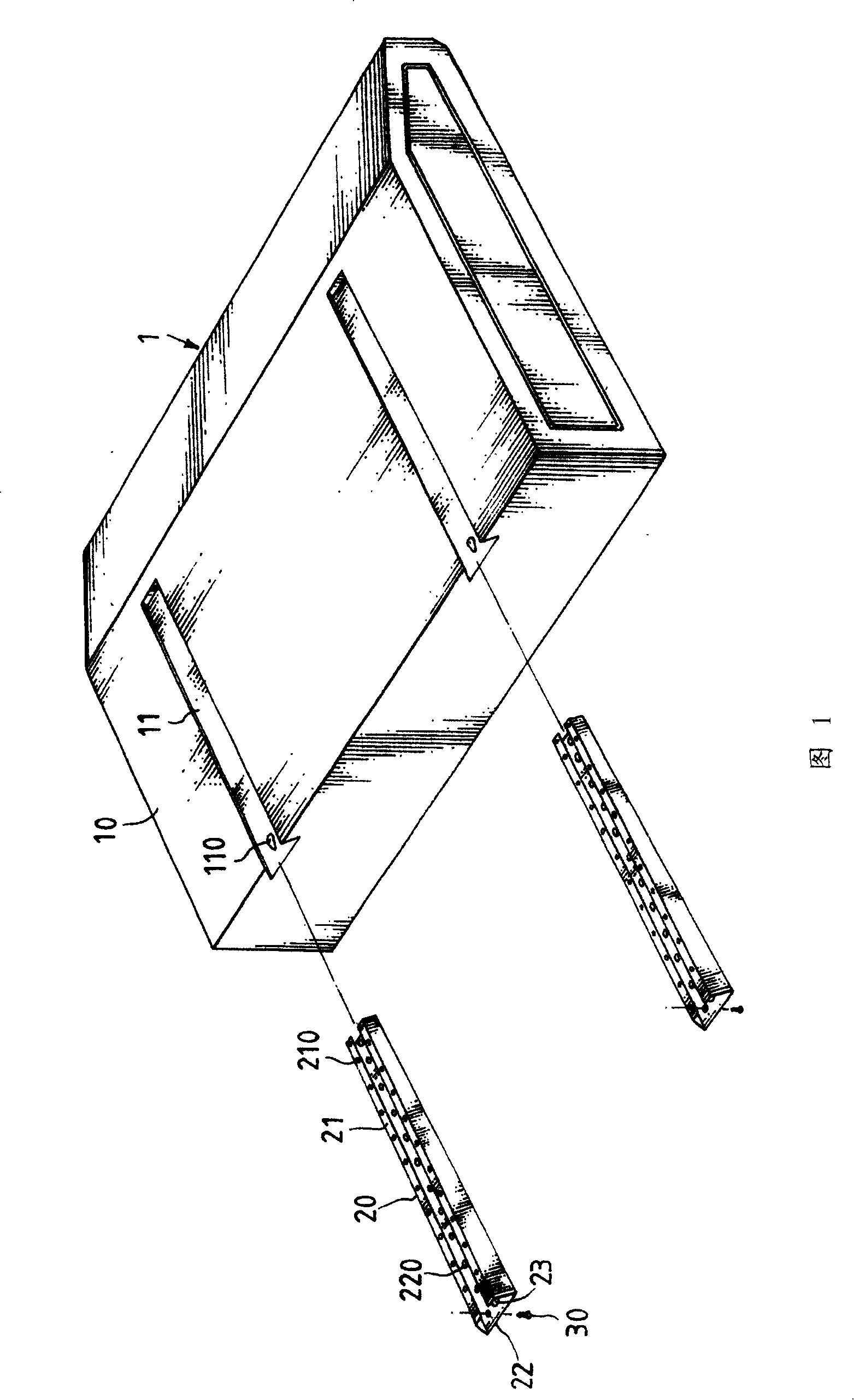

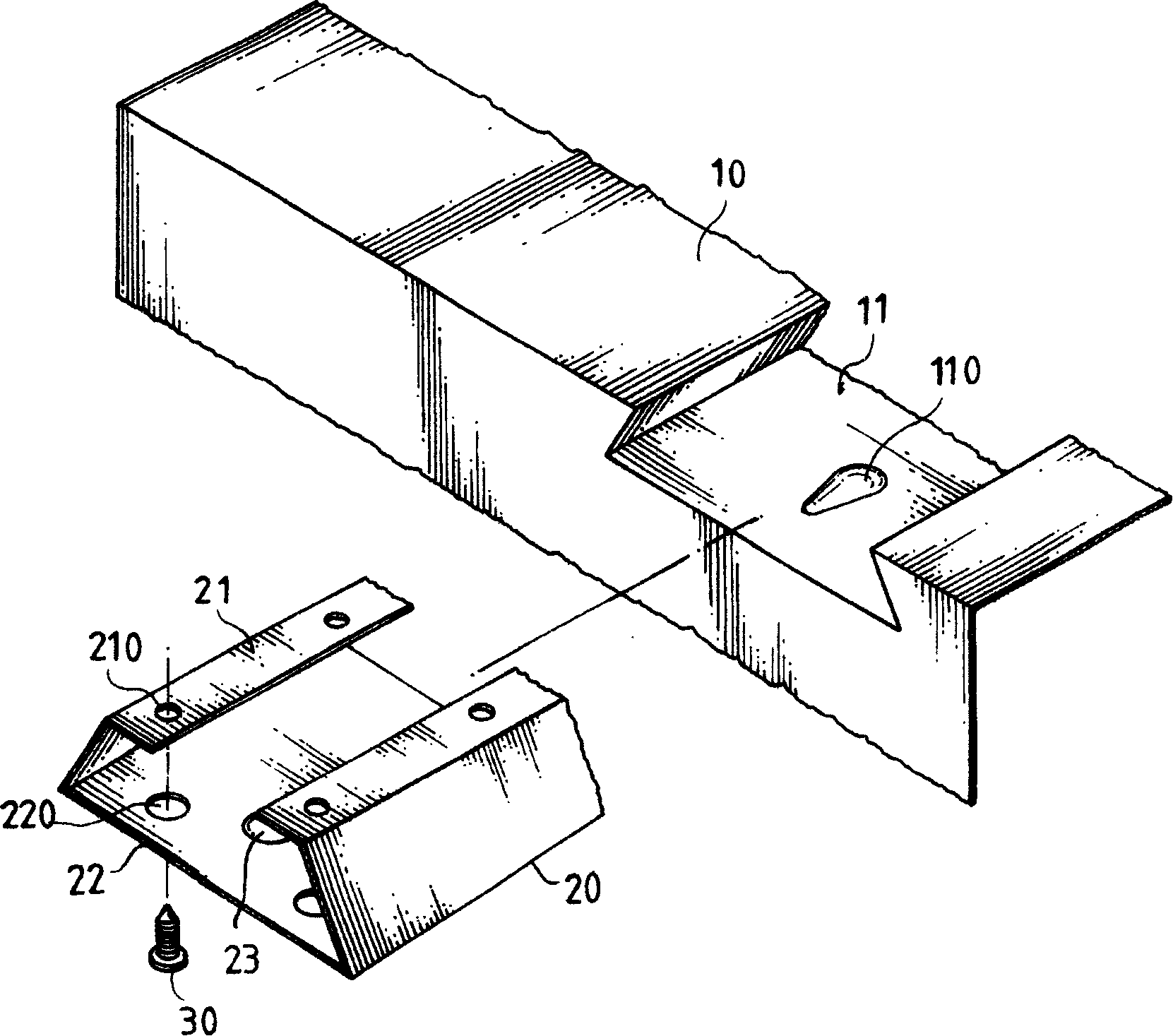

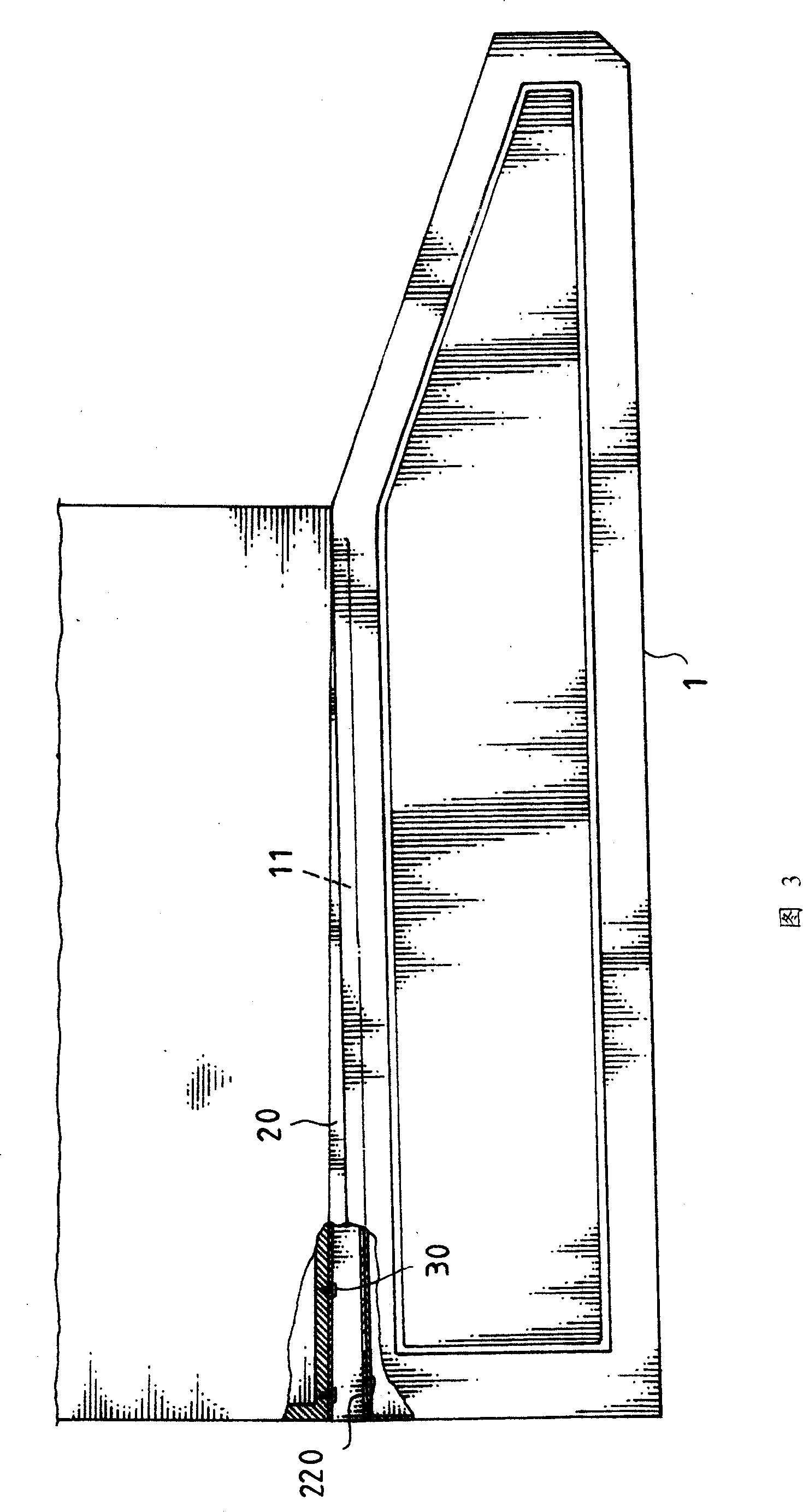

[0029] First, please refer to Fig. 1-Fig. 5, a slide rail type cooker hood fixing structure of the present invention is mainly provided with rails that can be inserted into each other on the top plate 10 of the range hood 1 and the hanging place. Groove 11 and rail 20, wherein:

[0030] The track groove 11 is in the shape of two parallel dovetail grooves with an appropriate depth. The front notch of the track groove 11 is provided with a positioning point 110, and the positioning point 110 can be a groove shape inclined downward from the front edge; The rail 20 is a dovetail-shaped bar body corresponding to the rail groove, and its top surface is provided with a horizontal folding surface 21 facing inward, and a number of rows of holes 210 are arranged on the horizontal folding surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com